about the process of mixing and grinding of cement

The Process of Grinding Concrete | MVL Concretes' Blog

Apr 02, 2013· The Process of Grinding Concrete. Posted on April 2, 2013 by mlatimer4351. Grinding concrete involves using an abrasive, mostly diamonds to grind the concrete surface down. There are many different grits (the size of the diamond smaller the number the larger the diamond) that can be used to grind concrete depending on how much of the surface ...

Manufacturing Process Grey Cement

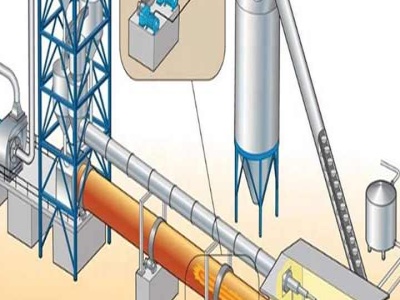

The production process for cement consists of drying, grinding and mixing limestone and additives like bauxite and iron ore into a powder known as "raw meal". The raw meal is then heated and burned in a preheater and kiln and then cooled in an air cooling system .

Why is gypsum added to the cement at the time of grinding ...

Why is gypsum added to the cement at the time of grinding, but not at the time of the initial mixing of ingredients? Update Cancel. a d b y L e m o n a d e I n s u r a n c e. Protect the stuff you love for 5/month. ... What are the process of grinding cement products?

Concrete Grinding, Cleaning Repairs | Detroit, MI ...

CONCRETE GRINDING. Surface preparation is the most important part of any decorative concrete flooring project. For the project to hold up over time, you must begin with a concrete that is clean, dry, and it's a brand new slab, this often means removing tile adhesive, thinset mortar, carpet glue or paint sometimes a combination of these residues.

Raw Materials for Cement Manufacture

The wet process, which was once standard, has now been rendered obsolete by the development of efficient dry grinding equipment, and all modern cement plants use the dry process. When it is ready to enter the kiln, the dry raw mix has 85% of the particles less than 90 £gm in size [2] .

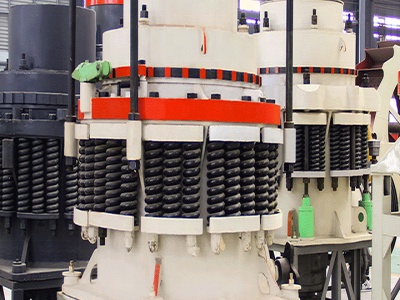

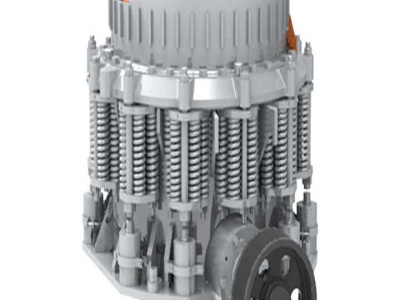

Cement Grinding Plant,Concrete Grinding Plant,China ...

China concrete grinding plant manufacturer. The cement grinding plant mainly used in crushing and preheating of raw materials, and grinding and packaging of cement, it's mainly applied to deal with industrial solid wastes like slag, coal ash, coal gangues, and so on. Therefore, it contributes great to the environment protection industry.

Cement Manufacturing Process: What is Cement made of.

Cement manufacturing process what is cement made of, it can be discussed conveniently under two headings: Selection of Raw materials and manufacturing methods. Raw Materials of Cement. Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method).

"The most important books of the Cement Industry"

Oct 10, 2015· One of the most complete books that can be found about Dry Process Cement Plant, covering the main aspects of it, from grinding to packaging. It shares relevant data .

Ordinary Portland Cement | The Civil Engineering World

Mar 10, 2017· In Pakistan, most of the factories use Wet Process for the production of cement. There are five stages in the manufacturing of cement by wet process: Crushing and grinding of raw material; Mixing the material in proportion; Heating the prepared mixture in rotary kiln; Grinding the heated product known as clinker

Chemical Composition of Cement University of Babylon

grinding. Table shows the approximate oxide composition limits of ordinary Portland cement. ... Setting and Hardening of Cement Setting Process: The process of losing plasticity with time and becoming dense, which is formed by mixing the cement and water. It happened in two stage initial setting and final setting.

Grinding | materials processing |

In cement: Crushing and grinding ntaining a charge of steel grinding balls. This grinding is done wet or dry, depending on the process in use, but for dry grinding the raw materials first may need to be dried in cylindrical, rotary dryers.

No. 1/2004 New cement grinding plant for the Koromacno ...

ty of the cement grinding plant. With the construction of the new grinding plant, the following objectives were aimed at beyond the increase of the grinding capacity:• reduction of the electrical energy •requirement by %, •increased reliability, •high cement qualities, further cement types with finenesses of 3500 to 5000 cm2/g.

Concrete Polishing Wet verses Dry Grinding Debate

Concrete Polishing Wet verses Dry Debate. Here's the misleading part. NO portable available vacuum system I have seen will capture close to 99% of the dust generated by heavy grinding, commonly used in the process of polishing concrete. These heavy initial grinding steps are usually done with large platform (32 Inch ) machines that generate huge amounts of harmful silica dust.

Volume 3, Issue 5, November 2013 Study of Processing and ...

Process of raw mill in grinding of raw material and silo storage 1. This stage continues after crusher lime stone stock pile. A belt conveyor collects the raw material from the stock pile with the help of hoppers below the stock pile. So these belts are fixed under the stock pile to collect the raw material.

OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING: .

In the cement industry, a heavy industry absorb ing extremely high energy, the automatic control of the grinding process remains a challenging issue, due to the elevated degree of uncertainties, process non linearity and frequent change of the set points and the respective model parameters during operation.

Cement grinding optimisation ScienceDirect

grinding the cement clinker nodules to 100% passing 90 μm in a dry circuit. Grinding occurs at the beginning and the end of the cement making process. Approximately tonnes of raw materials are required to produce 1 tonne of finished cement.

CEMENT PRESENTATION |authorSTREAM

THE CEMENT MANUFACTURING PROCESS 1. RAW GRINDING : The raw materials are very finely ground in order to produce the raw mix . 1. RAW GRINDING Raw grinding and burning 2. BURNING 2. BURNING : The raw mix is preheated before it goes into the kiln, which is heated by a flame that can be as hot as 2000 °C.

Cement Clinker Grinding Aids Mineral Processing Metallurgy

The use of a good Cement clinker grinding aid can be vital in today's increasing material demands. Along with the obligation to process increasingly larger quantities of ores containing finely disseminated minerals, our limited energy resources and the rising costs of energy present a challenge to the process engineer. One research route that has been explored for about half a century is the ...

The impact of mechanical grinding on calcium aluminate ...

Calcium aluminate cement (CAC) was ground for 1 and 2 h to investigate the impact of mechanical grinding on CAC hydration at 30 °C and CACbonded castable strength. Phase composition and microstructure of unground and ground cements after hydration for predetermined times and terminated by the freezevacuum drying were compared.

Contrast Between Dry and Wet Concrete Grinding Methods

DRY CONCRETE GRINDING. The dry concrete grinding method is used to polish concrete, whether it is for floors, walls and countertops or something else. While they both are used for the same result, the truth is that their procedures are different. The dry grinding process is usually done using a machine that measures about 32 inches in diametre.

burning and grinding of cement

Step 2: raw grinding and burning Grinding produces a fine powder, known as raw meal,, manufacturing of cement mixing grinding and burning, cement . Inquiry; Coal in the cement industry. Coal in the cement industry Cement manufacturing consists of raw meal grinding, blending, pre calcining, clinker burning and cement grinding Limestone, CaO, SiO2 .

Concrete Ingredients and Mixing of Concrete | CivilDigital

Sep 17, 2013· Concrete Ingredients and Mixing of Concrete . Definitions of Terms Associated with the Materials used in Concrete. Cement: a dry powder made by burning limestone and clay, and then grinding and mixing to an even consistency. : a mixture of stone aggregates, sand, portland cement, and water that hardens as it dries.

The Process for Making Portland Cement Concrete Alberta

The Process for Making Portland Cement. Ingredients used in this process are typically materials such as limestone, sandstone, marl, shale, iron, clay, and fly ash. The kiln resembles a large horizontal pipe with a diameter of 10 to 15 feet (3 to meters) and a length of .

Latest Posts

- إنشاء مصنع إثراء الذهب 1000 طن في اليوم

- شركة مصر الشرقية لتعدين الذهب

- سحق حجر فلوريدا الجنوبي

- موردي معدات تعدين الكروم في اليمن

- قطع غيار مورد كسارة في العراق

- إجراء سحق كربونات الكالسيوم الأردن

- كسارات خام الحديد وحجمها

- منتجات ماكينات زراعية مصر

- استشارة كسارة الفحم

- مطاحن المطرقة للبيع الجزائر

- تستخدم كسارة الحجر في اليمن

- مزدوجة رمح المطرقة محطم الحجر الجيري الحجر

- موقع مصنع كسارة الحجر

- شاشة تهتز منخفضة السعة

- هل لديهم باو إيتي في الجزائر

- crusher dan pabrik yang digunakan

- sand river technologies

- china belt conveyors

- batu biaya mesin crusher di australia

- menghancurkan produsen peralatan di jerman

- pcb milling machine china

- where is fluorite applizenithion

- flowchart of how line ore is processed

- limestone quarry mining procedure dec

- medium milling machine

- crashing machine for stones

- gravel crushing outfit for sale customer case

- cnc caseera marmol

- crusher working demo figure

- gaap akuntansi untuk tambang batu