all process parts of cement plant

Cement Plant Machinery Parts at Best Price in India

Cement Plant Parts Rs 750/ Piece(s) Get Latest Price In order to keep pace with never ending demands of customers, our company offers excellent quality range of Cement Plant Metallic Cement Plant Metallic Bellow is checked under various set norms of the industry.

Cement Manufacturing/Manufacturer Plants | Cement Plants ...

Our cement plants in India have grown manifolds in terms of capacity; we are also acquiring some new plants to increase the volume and expand further. We have cement manufacturing plants in southern states of Tamil Nadu (Dalmiapuram Ariyalur) and Andhra Pradesh (Kadapa), with a capacity of 9 million tonnes per annum.

How Cement Is Made

Cement plant laboratories check each step in the manufacture of portland cement by frequent chemical and physical tests. The labs also analyze and test the finished product to ensure that it complies with all industry specifications. The most common way to manufacture portland cement is through a dry method.

Holcim Portland Cement Plant LafargeHolcim US

world and the leading cement producer in the United States. Headquartered in Chicago, Illinois, we have resources across the country, whether operating under the name Lafarge, Holcim, Aggregate Industries or Lattimore Materials. About the Holcim Portland Cement Plant The Portland cement plant is a dry process cement plant since 1996

Cement Plant Process and Instruments Used SlideShare

Oct 22, 2015· A brief presentation on Cement Plant Process and Instruments Used in Cement Plant. Slideshare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If you continue browsing the site, you agree to the use of cookies on this website.

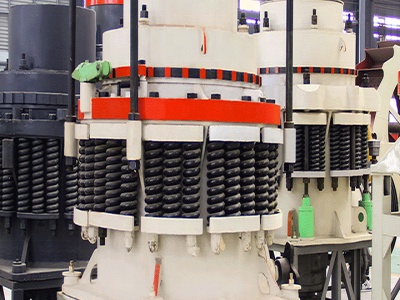

Batch Plant and Central Mixer Operations Manual CONE .

The VFD is located in the plant main electrical service panel. The speed of the conveyor is controlled by the batch control using the faster and slower function. The conveyor will operate in a range from 1/3 of full speed to full speed. Three outputs are required from the batch control to operate this batcher.

Sustainable production with a new cement plant | FLSmidth

Our process and engineering specialists guide and support you through all stages of a cement plant. In the early stages, we help with feasibility studies, project development and financing. Our engineers then design a new cement plant to meet your specific requirements.

Ohio cement plant looks to wind to reduce footprint of ...

Apr 19, 2019· The cement plant is expected to continue operating for several decades, so a longterm power purchase agreement makes sense. And there is a lot of acreage at the site. LafargeHolcim mines limestone on some parts of the site, which spreads over several hundred acres. The three turbines will sit on part of the site that was formerly a quarry.

Criteria for Production Control of Ready Mix Concrete

This document provides detailed criteria of plant, machineries, testing facilities, control on the properties of concrete ingredients and the final product, technical manpower, etc; which any RMC plant, irrespective of their size and capacity, must fulfill to qualify for the certification. The document is divided in two parts Section A

process of production of cement plant

Cement Production Process 1 By: Deepesh Kumar Mishra Satna Cement Works Birla Corp Ltd Six Weeks Training Report 2 Satna Cement Plant 3 Counted amongst the larger plants of the Cement Division, Satna Cement Works and Birla Vikas Cement at Satna (MP) along with Raebareli Cement Works (UP) have an installed capacity of 236 million .

Lehigh Cement Co. plant is cemented in history • Aggregate ...

The plant produces 10 tons of dust every hour, so recycling it right back into the cementmaking process is important. Charles Bortz, environmental coordinator, said the Evansville plant has made tremendous strides in keeping up with all DEP and EPA regulations.

700,000 TPY Cement Plant for Sale at Phoenix Equipment ...

Phoenix Equipment is a global buyer and seller of used chemical and petrochemical processing plants. We currently have this used 700,000 tpy cement plant for sale, immediately available for purchase and relocation. Call Phoenix Equipment today to receive a quote and additional information on our used chemical process and cement plants for sale.

Cement Manufacturing Process JK Lakshmi Cement

Cement Manufacturing Process JK Lakshmi Cement, a member of the prestigious Organisation, is a blue chip company with an annual turnover of over Rs. 2300 crores (Rs. 23 billion). Launched in 1982, JK Lakshmi Cement (Sirohi Plant), an ISO 9001:2008 14001:2004 company, is built over an area of about 8 square kilometers, amongst the lush ...

Products Services | Manufacturer from Nalgonda

The company has its captive power plant of 50 mw capacity at Sankarnagar to cater to the energy needs of our cement plants in Tamil Nadu. Another captive power plant of 50 mw at Vishnupuram in Andhra Pradesh has been installed and it is under the process of commissioning.

Thermodynamic Analysis of Cement Production Process .

ergy efficiency of the whole plant without the chemical exergy. It was found to be %. This conforms to the pattern found in previous exergy analysis of cement production process [13],[15]. The total amount of exergy into the system is /hr and the total exergy out is /hr. The exergy loss of the system is /hr.

Cement Plant Exporters in India

Our gamut of cement plant and machinery is repetitively demanded by our domestic and international clients. We are manufacturing, exporting and supplying various components such as rotary kiln cement plants, vertical shaft kiln cement plant, cement project machinery, mini cement plant, grinding plants and grinding plant and

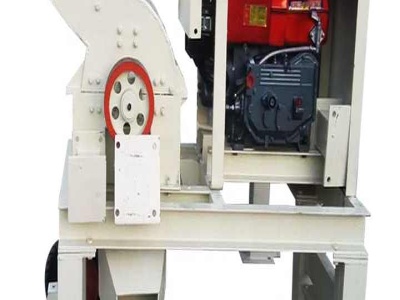

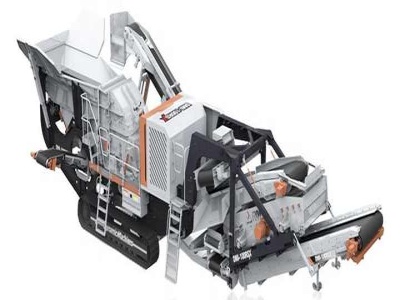

impact crusher machine for cement manufacturing process ...

Impact Crusher Machine for Cement Manufacturing Process, Impact Crusher for Cement Manufacturing Process 1 The cement manufacturing process begins when limestone, the basic raw material used to make cement, is transported by rail to the Edmonton plant from the Cadomin limestone quarry 220 kilometres west of Edmonton

cement plant layout design | Model Railroad Hobbyist magazine

This cement plant on my layout combines kitbashed parts from several kits along with scratchbuilt components. The model ships bulk cement and also receives inbound gypsum and coal. It only requires a few inches of depth along a narrow shelf.

Cement Plant Machinery Walchandnagar Industries

Cement Plant Machinery. OVERVIEW. Since its inception in 1963, the Cement division of WIL has been providing reliable and robust solutions for the cement industry both in India and abroad. We undertake complete responsibility for the design, engineering, manufacture, supply, project management and supervision of erection commissioning of all ...

China Complete Small Cement Production Plant China ...

These two main cement production machinery realize the main processing" two grinding one burning".In dry method portland cement plant, the grinding process consumption more than 60% power of the whole plant,including raw materials grinding 30%,coal powder grinding 3%,clinker grinding 40%,so to choose the suitable and save energy grinding ...

ABB process control solutions for cement plants ABB ...

Cement and glass makers need integrated process control systems that can improve plantwide efficiency and productivity. Our awardwinning process control solutions provide easy "single window" access to the process, production, quality and business information – from the most remote location to corporate headquarters.

Latest Posts

- المملكة العربية السعودية تستخدم كسارات التعدين

- مخروط كسارة الصخور الحديد الزهر المعاد تدويره

- مصنعي كسارة فكية يمنية

- آلة الخرسانة كسارة مخروط هيدروليكية

- كسارة الفك من كوريا الجنوبية

- سطح تحكم الكسارة 2012

- مصنع تكسير الكوارتز عالية الانتاج للبيع بالجملة

- تستخدم مغذيات حزام الصخور بيع

- الشركات المصنعة للالفك لمحطم الفك في مصر

- رخام كربونات الكالسيوم

- حجر الفك محطم آلة للبيع

- تستخدم الدولوميت تأثير كسارة لتأجير الأنجولا

- كسارات الرمل على نطاق صغير في الصين

- البنية الداخلية للاسمنت طحن مطحنة

- طحن مطحنة الكرة حساب الوسائط

- sub zero for gold extraction

- mining method for bauxite

- gold mining equipment for sale in ireland

- free pdf apptitude book by rk jain

- directed vibrating screen

- penghancur batu dari cina

- zenith mining equipment for iron ore washing

- large capacity steel linear vibrating screen

- buy rubber mill machine rubber mill machine

- hydraulic roller crusher cement mill

- industrial appliion of dolomite filler rock crusher mill

- mastercam x5 milling prices

- crusher grinding burnaby

- ball mill producer malaysia

- iron ore beneficiation plant suppliers samac