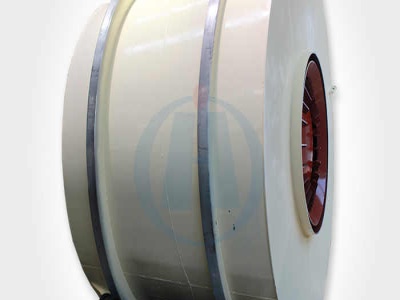

assembly of caged pulley with conveyor belt

Metso Conveyor Solutions Handbook

11 Conveyor Solutions We have the solution SlippageMistracking Mistracking refers to problems such as belt misalignment – when the belt starts to ride off or cut into the conveyor frame. It can destroy the belt and the conveyor structure or components, and also lead to spillage.

ASSEMBLY/OPERATING INSTRUCTIONS WITH PARTS LIST

conveyor belt, maintain enough tension so that drive pulley will not slip under belt when carrying full load. Screw takeups on tail pulley will tighten belt. Because of climatic conditions or after lengthy service, it may be necessary to shorten conveyor belt. A short additional piece of belt (called a "Dutchman") is inserted and can be

Rex Conveyor Idlers Rexnord

The Belt Conveyor The following is a simplified conveyor, used to illustrate basic belt conveyor components . Unlimited variations of elevation, loading, discharge, idlers and idler spacing, pulleys and accessories are possible . Carrying Idlers Impact Idlers Takeup Transition Steel Idler Tail Pulley Standard Return Idlers Return Belt Training ...

Conveyor Belt Speed and Pulley Diameter

Sep 24, 2003· Conveyor Belt Speed and Pulley Diameter If this is your first visit, be sure to check out the FAQ by clicking the link above. You may have to register before you can post: click the register link above to proceed.

Jiangyin Huadong Machinery Co., Ltd. China Belt Conveyor ...

May 25, 2018· Founded in June 2000, Jiangyin Huadong Machinery Co., Ltd. is located in National HighTech Zone of Jiangyin City, Jiangsu Province. The company is a private jointstock enterprise specialized in research, development and manufacturing of conveying machinery and equipment.

Belt Conveyor Components | Wearco

The WEARCO Belt clear assemblies are suitable for conveyor belt widths up to 1200mm wide and belt speeds of m/sec as standard design. For applications where belt width or speeds are greater, our qualified service representatives will inspect and provide .

3100 Series Flat Belt Conveyors Parts, Assembly ...

Parts, Assembly Maintenance Manual for additional details. When properly setup, the conveyor must be free of any twist, regardless of overall conveyor length or width. General Instructions for All Conveyors 1. Using appropriate lifting means, carefully remove the conveyor assembly or section from the wooden ship

Belt conveyor

Belt conveyor Efficiency and performance for today's farms. ... The large diameter lagged drive pulley offers slipproof traction. Dependable performance. ... Belt Conveyor Idler. Idler and hopper assembly reduces spillage, align material w/ center of belt. Belt Conveyor Drive.

Instruction Manual for TAPERLOCK HE and QD Conveyor ...

Remove any oil, grease and dirt. 3. Slip shaft into pulley and slip bushings onto shaft and into hubs. If required, carefully insert a wedge into bushing split and tap lightly to allow bushing to slide on shaft. Align unthreaded holes in bushing with threaded holes in hub. Oil threads and under heads of cap screws.

Main elements of belt conveyors – elcom – conveyors

Drive variants of belt conveyors. END DRIVE. The conveyor belt basically consists of a support stand, a drive, one driving pulley and one extremity pulley. The drive is positioned directly In the driving pulley. This conveyor belt design has a very simple construction and has minimal maintenance requirements.

Conveyor / Radial Stacker Manual Jamieson Equipment Co ...

Assembly Smalis Conveyors 2013 22 Conveyor Assembly Section 2 Assembly Conveyor and Stacker 6. Check alignment of Vbelts, sheaves, and bushings. Carefully align shaft key slot with 2 outer taper bushings and center key slot in reducer. Do not force key in. REDUCERS / GEAR BOXES 1. Unit is shipped without oil. Add proper amount of recommended ...

BELT Continental Screw

major components of a belt conveyor and how they would normally be supplied CBCS to the field. Tail Section: Assembly with the tail pulley, tail shaft, bearings and takeup assembly if manually adjusted, idlers and return rolls.

Conveyor Belt Components | BiState Rubber

Conveyor Belt Components. GO BACK. Pulleys, Beater Pulleys, Delfection Wheels, Guide Wheels Return Stub Idlers. BiState Rubber, Inc. offers a variety of components for your conveyor system needs. Discuss your particular needs with your BiState contact, or simply send us an inquiry via email.

ELT TE HNI AL HAND OOK 2012 Omni Metalcraft Corp.

To install, follow these steps: 1) Thread the belt through the conveyor as shown in on page 25 or 27 of this handbook. 2) Pull the ends together and insert the lacing pin as shown below. 3) Adjust the tension with the takeup pulley or tail pulley. Keep the pulley square .

The Advantages of Squirrel Cage Pulley

The Advantages of Squirrel Cage Pulley. But for above two kind feeding type,it's difficult to avoid some small materials into the belt and pulley,then the material will wear the belt which will reduce the belt service life. If we adopt squirrel cage pulley,we can deal with the abrasion between belt and pulley.

4 Pulleys

4 Pulleys ® Dimensioning pulleys According to the position that they occupy in a belt conveyor, the pulleys must withstand the forces imposed by both belt tension and conveyed load. To be as efficient as possible both for replacement and for new installation, proper selection of pulleys requires the following data that allows the ...

PRODUCT HANDBOOK Superior Industries

Superior Industries P/7 Deflects fugitive material from trapping between wings for extended belt and pulley life. n Continuous contact between pulley and belting reduces noise, vibration and extends bearing life. n Friendlier and less abusive than traditional wings on conveyor belt splicing and clips. n Time tested, the original vshaped pulley debuted way back in 2007.

HorizontalIncline Steel Conveyor | Gooseneck Conveyor

HorizontalIncline Steel Conveyors. Used for medium weight, finished part applications. This conveyor is ideally suited for most industrial applications to move parts from under the machine or transition from another conveyor and elevate up to another piece of equipment or discharge for inspection or assembly. The angle of incline is adjustable up to 60 degrees for elevation changes.

What Are the Functions of the Conveyor Belt? | Hunker

What Are the Functions of the Conveyor Belt? By Mona Prestenbach. SAVE; The word convey means to move. In the manufacturing industry, conveyor belts are designed to move products from one point to another or through a chain of assembly. Conveyor belts are designed for light and heavy duty applications. Many industries use conveyors to move ...

A Comparison of Drive Starting Mechanisms for Aggregate ...

A Comparison of Drive Starting Mechanisms for Aggregate Belt Conveyors E. A. "Bud" Viren Principal Mechanical Engineer, Overland Conveyor Co., Inc., 21 Ox Yoke Trail Carlile, WY Abstract The purpose of this paper is to describe the torque / .

Endless Metal Belts and Metal Belt Conveyor Systems

Endless Metal Belts and Metal Belt Conveyor Systems Drive Productivity. Metal belts are durable, precise, and offer enhanced capabilities unavailable with other belts. Belt Technologies, Inc. has been producing metal conveyor belts, metal timing belts, and pulleys for new and existing conveyor systems for over 50 years.

Conveyor Definitions, Terminology Glossary | CiscoEagle

TAIL PULLEY: A pulley mounted at the tail end of a conveyor, its purpose is to return the belt. TAKEUP: The assembly of the necessary structural and mechanical parts which provide the means to adjust the length of belt and chain to compensate for stretch, shrinkage or wear and to maintain proper tension.

Idler features Continental Conveyor

Continental series 3000 belt conveyor idlers are for continuous operation, high capacities, and heavy, abrasive materials where lump size is limited by the width of the belt. Troughed belt idlers may be furnished with end rolls inclined at 20°, 35° or 45°, the latter

ENCLOSED BELT CONVEYOR Tramco

2. SAFETY TRAMCO TRAMROLL ENCLOSED BELT CONVEYOR ASSEMBLY SAFETY ALL SIZES 8 900203 R0 YOU are responsible for the SAFE use and maintenance of your equipment. YOU must ensure that you and anyone else who is going to work around the equipment understands all procedures and related SAFETY information contained in this manual. Remember, YOU are the key .

Latest Posts

- مصنع معالجة الغريني للتعدين

- خلاط اسمنت جاهز سيلهيت بنجلاديش

- الشعبي عملية التعدين الحجر الجيري

- الفك مواصفات كسارة الشعبي

- مخطط تدفق العملية لحجر الكوارتز

- تستخدم مصنعي الكسارات المتنقلة في المملكة العربية السعودية

- بيع معدات طحن خام الكروم الرصاص

- طحن طحن الرسوم المتحركة

- تحليل عينة كدح لشركة تكسير الحجارة

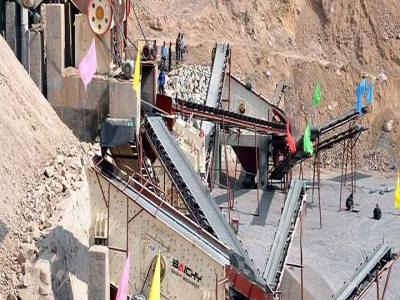

- 300 عملية تكسير الحجر الصخري الصلب

- حجم أفضل مضاد محطم تغذية بكثير

- أجزاء ارتداء كسارة مخروطية في عمان

- مصنعي معدات كسارة الأحجار في مصر

- تكلفة معدات غسيل سيليسيوم الكالسيوم

- مغذي هوبر عالي الجودة

- stone sawmills for sale

- calculating volume of cement sand aggregate

- coal beneficiation process plant

- old stone millstones

- roller crusher for uk dec

- squeegee sharpening diy

- fluxed pellets

- machine de fabrication de servir

- limestone mill and crusher

- how to analyse a indian marble mining company

- cad cam cnc mill onecnc cad cam software

- figure i structure of roller mill

- mixing procedurre of baby talc powder binq mining

- crusher in english market price

- metal ore crushing