ball mill design parameters

Grid Type Ball Mill, Ball Mill Design, Wet Type Grid Ball ...

In order to avoid over crushing, the client selected Xinhai wet type grid ball mill in grinding process. The grinding medium are steel ball and ore itself, the grinding efficiency is high, it also adopts the hydrostatic and hydrodynamic bearings, which ensures the smooth operation and easy to grinding.

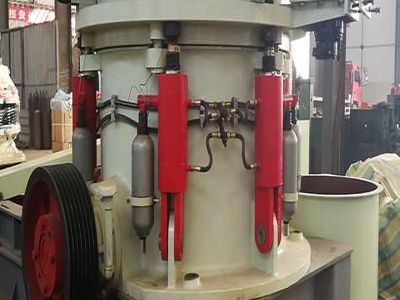

design parameter for hydraulic ball mill machine

design parameter for hydraulic ball mill Mineral . design parameter for hydraulic ball mill Advanced structure and drive design strong crushing capacity new sand making machine a full set of mineral processing equipment milling flour milling machine ball mill Quotation More Oil Palm Tree Bark Cutting Wood Chipper Crusher Machine Buy. Live Chat

design parameters for a ball mill

design parameters for a ball mill parameters to design a ball mill raymond mill carsnbike, 14 Jan 2014 and shaft rotation speed and mill design parameters such as ball load, pin Ball Mill Price [PDF] Determination of breakage parameters .

MODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLING .

you cannot use work index analysis for the same purpose on ball mill circuits because of the complex interactions between grinding and classification. In this module, you will learn how to relate design and operating variables to ball mill circuit efficiency through functional performance analysis*. This Introduction is seven pages long.

THE OPTIMAL BALL DIAMETER IN A MILL Strona główna

parameters of both distributions are equal in Eqs. 7 and 9: m c. (10) In the second part of the paper, we will investigate the hypothesis defined by Eqs. 8, 9 and 10. 3. Experimental Investigations were carried out in a laboratory ball mill having the size of DxL = 160x200 mm with a ribbed inside surface of the drum. The mill ball loading was 40%

ball mill operating parameters of ball mill

Ball Mill Design Parameters Of Vibrating Screen. CAT Crushers Design Parameters Of Vibrating Screen ball mill operating parameter. Ball Mill Operation Grinding Circuit Startup Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started. Check the ore

design parameters for a ball mill trough belt grinding

design parameters for a ball mill trough belt grinding; design parameters for a ball mill trough belt grinding. ... Technical parameter of GM1840 ball mill grinder: ... We will provide you with the prior plan, process flowchart design and production... Chat Online.

steel ball mill design

Rod Mill and Ball Mill Sizing Parameters. Contact US Ball Mill Manufacturer, Ball Mill Manufacturer . Techno Designs. Techno Design India is leading Ball Mill Manufacturer Exporter. . Our stainless steel ball mills are used to grind ores and minerals from a feed size of 6mm and. Contact US (PDF) DESIGN AND FABRICATION OF MINI BALL MILL . Aug 1 ...

SME 2009 Impact on Grinding Mill Design and Recent New ...

to Bond BM Wi is a key parameter in a SAG mill grinding circuit design, because this ratio controls the power split between SAG and ball mills at the design T80 (transfer size). INTRODUCTION Three recent major projects involving a review and testing by Starkey Associates, have shown that consulting

Which Design Parameter Calculet For Hammer Mill YouTube

May 16, 2019· Design, Fabrication, Laboratory Size Hammer Mill To calculate the shaft speed...Hammer Mill Design Mini Project Coke (Fuel) Coal .A MINI PROJECT ON A STUDY OF HAMMER MILL DESIGN In partial ...

ball mill sizing and design

Ball Mill Design Power Draw Tool Parameters Values displayed with a may be changed click on a value to display an entry form or use the arrows right of a value to select from a list. ball mill sizing and design new technology coal water slurry design grinding mine ball mill. US 50000 250000 . ball mill sizing, ball mill ...

A Parametric Design of Ball End Mill and Simulating Process

A Parametric Design of Ball End Mill and Simulating Process Liyong Chang Ball end mill cutter is widely used in precise CNC machining as a high efficiency processing tool for complex surface. On the basis of the literature review about mathematical model, grinding machining process, cutting experiment of ball end mills,

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING .

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS ... Breakage mechanism in tumbling ball mills 20 Impact breakage 21 Abrasion breakage 21 ... Experimental design 47 Monosized media charges used 47 Selection function parameters 54

ball mill sizing and design

Ball Mill Design/Power Calculation The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be. ball mill sizing and design smoothfabcoza. ball mill sizing and design ball mill for cement grinding One, ball mill sizing and design,Proven mill design 6 Mill body The mill ...

Ball Mill FEA Analysis | Analyzercae

Aug 26, 2017· Design parameters material properties extraction for Complete BallMill. Determining the various loading conditions affecting strength of the BallMill. Preparing FEA Model for BallMill with complete structured Hexahedral Mesh. Solving the FEA Model Result extraction

Optimizing the operation of the cement mill | Industrial ...

Ball mills account for the majority of all mills in cement plants and therefore the optimization of established ball mills implies high savings potentials. Parameters that hold potential energy savings are load level, revolution speed, combination of the ball charge, lining design and the adjustments of the separator. Standard optimization methods include meter sampling of the effective length ...

ball mill design calculation venta

design calculation of ball mill . The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum ...

fly wheel design calculation of ball mill

Ball Mill Design/Power Calculation 911 Metallurgist. Apr 8, 2018 . The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground,. Get Price Materials for Flywheels Granta Design. What criteria govern the choice of material for a flywheel? The Model.

design ball mill

Ball Mill Design/Power Calculation. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the ...

Ball End Mills | Regal Cutting Tools

Ball end mills are used for drilling shallow holes, slotting a channel where a flat bottom is not required or most commonly used to produce multidimensional contours in molds or dies. The design of ball end mills forms a hemispherical cutting action identical to the diameter of the tool. Because of the shapes required in these products it's common that multi axis machining

A Method of C alculating Autogenous/ SemiAutogenous ...

when received by the following ball mill, gives a credit to the ball mill SE. When assessing the operating work indices using the plotted 80 per cent passing values the rod mill averages an ineffi ciency value in the region of because the design 80 per cent passing value is not achieved. The ball mill usually

ball mill design parameters

Ball Mill Design/Power Calculation Traduire cette page. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 ...

Latest Posts

- أسمنت في الصين الميكا

- طن لكل ساعة طحن الأسمنت

- سعر آلة رمل مولر

- آلة الجير مسحوق الحجر الجير

- شركة معدات محطم في ايران

- معدات تعدين النحاس في جنوب غرب كارناتاكا

- مزود كسارة الفك في مصر

- فصل الكاولين والرمل الزجاجي

- سعر آلة معالجة الذهب الجزائر

- مطحنة الكرة النثر الغناء ir على خام الصين

- حزام سير مطحنة الكرة الجزائر

- الكرة المصنعين مطحنة في rajapalayam

- كسارة دوارة نوع الكسارة

- مصنع الأسفلت المتنقل الصغير المستخدم في المملكة العربية السعودية

- كسارة الصخور للنحاس

- stone quarry equipment for sale in nigeria

- iron ore spot price

- construction and working of powerful crushers

- mica quarrying equipment supplier

- vertical roller mill for cement cost price

- rotogravure cylindes grinding machine

- business industry agriculture in floydada

- feldspar powdering ball mill

- bzmachine cosmetics manufacturing ethiopia

- used ammann easy batch

- jfpi corporation mining company

- co2 extraction machine for sale prices

- beer recycling in andhra pradesh india solution for mining

- multipurpode of grinding machine diagrsm

- artisan gold mining machinery