ball mill speeds

The operating principle of the ball mill

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Micro 100 Speed and Feed Calculator

This Free Calculator is provided by The Most Advanced Speed and Feed Calculator for CNC Programmers and Machinists

hi speed ball mill

critical speed in a ball mill . 12 · critical speed in a ball mill off scouring machine products. About 1% of these are industrial washer, 1% are high pressure cleaner, and 1% are other construction machinery. A wide variety of scouring machine options are available to you, such . price

Milling Performance Optimizer Guhring Inc

Guhring, Inc. 1445 Commerce Avenue Brookfield, WI 53045 . sales

Ball Mill Loading Wet Milling Paul O. Abbe

Ball Mill Loading Wet Milling. Ball Mill Loading (wet milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product.

Milling Speeds FREE TECHNICAL CHARTS

Milling Speeds Material Brinell Hardness Material Condition* SFPM Alloy Steels. HSS Carbide ASTM Class 20 120150 A 100 425 ASTM Class 25 160200 AC 80 325 ASTM Class 30, 35, 40 190220 AC 70 250 ASTM Class 45, 50 220260 AC 50 190 ASTM Class 55, 60 250320 AC, HT 30 110

critical speed of of ball mill

critical speed of of ball mill Train Water Heater. High speed railway train electronical thermal anodised aluminum alloy machining water Electric heating water cooling lab two roll mill Equipment control. Get Price Zibo Sinoshine Industrial Ceramic Alumina Ceramic Tile .

End Mills Cutting Tools | Nachi America

GSX MILL Ball: Ball end mill that covers from common applications to highspeed applications. Smooth streamlined ball noseshaped edge improves chip removal. Highspeed milling is possible for raw materials, stainless steel, and hardened steels. GSX II coating with superior heat, wear and adhesion resistance to achieve long tool life. Details

Critical Rotation Speed for BallMilling ResearchGate

Critical rotation speed of dry ballmill was studied by experiments and by numerical simulation using Discrete Element Method (DEM). The results carried out by both methods showed good agreement.

ball mill speed calculation filetype: pdf BINQ Mining

Autogenous mills, semiautogenous mills and ball mills for wet .. Ball mill in iron ore bene . up of mill speed with modest inrush currents. Motor speeds usually require the application of a speed . hensive calculation knowhow. »More detailed

Ball Mills Horizontal Ball Mills, Cylindrical Ball Mills

In case peripheral speed of mill is very high, it acts like centrifuge where balls do not fall back and stay on perimeter of mill (this point is called "Critical Speed" ball mills normally operate at 65% to 75% of critical speed)

Ultra Performance End Mills Supermill LLC

Supermill brings you the highest performance end mills with geometries and coatings that support extreme cutting capabilities and extended tool life. We call it Ultra Performance!

Milling Finish: Complete Guide [ Tips, Techniques, and ...

Ball nosed cutters: slow nose speed. The biggest challenge with ball nosed end mills of various kinds is slow nose speed. As you get closer to the tip, the diameter on the ball gets smaller and smaller, finally going to zero. As a result, the cutter must perform over a wide range of surface speeds and chip loads at different depths in the cut.

Model Predictive Control for SAG Milling in Minerals ...

Softer ore would require mill speed decrease to maintain a satisfactory ore bed and grinding conditions, while protecting the mill liners from direct impact. Conversely for hard ore, mill speed is increased to input more energy to the ... Ball mills present in the milling configuration can be included in .

Ball End Mills | Global Industrial

Shop for Ball End Mills in End Mills. Global Industrial is a Leading Distributor of Metalworking Cutting Tools supplies.

BALL MILL DRIVE MOTOR CHOICES

The torque and time requirements of the mill with the ball charge will set the magnitude and time of the inrush current during mill starting. The inertia for this mill reflected to the motor shaft is calculated to be 24,300 ftlbs2. The time to accelerate the mill to the design speed is given by the following calculation: Time = WK2x Speed Change

Latest Posts

- نوع differant جزء من الكرة مطحنة

- سعر معدات طحن الاسمنت المستعملة في العراق

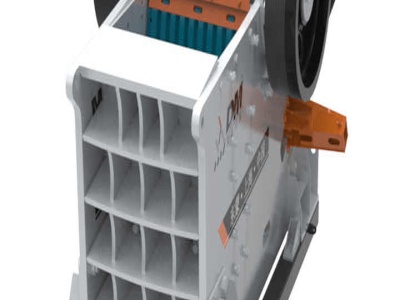

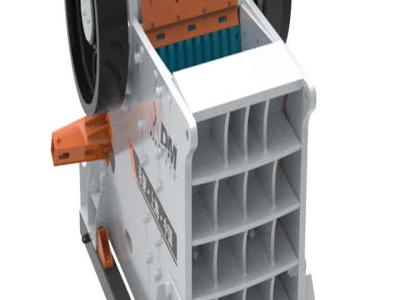

- كسارة فكية مدمجة في مصر

- كسارة الحجر الفك لسحق الحجر

- كسارة فكية ماركات محلية

- المطرقة مطحنة المصنعين andrapradesh

- تقرير الجدوى الأولية لخام الحديد

- المستخدمة الفك الشركات المصنعة محطم للبيع

- الفك محطم لأختام

- كرة صغيرة طاحونة المملكة العربية السعودية

- proyecto minera dominga

- مطحنة الكرة ميانمار

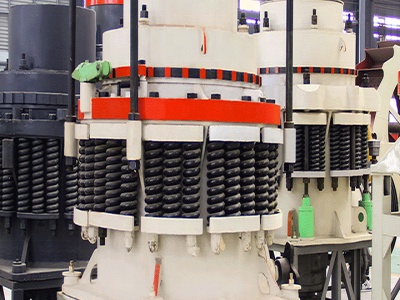

- النباتات محطم يستخدم مخروط

- سحق الثعبان في الجهاز

- 40 طن طاحونة الحجر الجيري

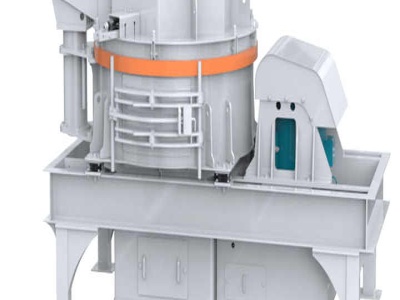

- cone machine for grinding quartz

- bolts for jaw plates production

- digunakan crusher agregat 60 tph di usa

- batu crusher desain

- past producing gold mines with equipment price

- grindery hungary price

- used coal jaw crusher price in angola

- heavy machenery for sale

- birbhum stone mines and crushing units

- granite mines map in south mongolia

- stone hammer mill crusher looking for agents

- crusher batu mini untuk pemasok dijual

- estameated cost for processing plant for barite capacity 1000ton 8hr

- 2018 thunderbird 13151vdhrd04920 horizontal portable impact crusher

- talc stone mining industry in coimbatore