basic parts of a grinding machine

basic grinding machine accessories

basic parts of a grinding machine privilegeresorts. Basic principle of grinding machine. is grinding machine? A grinding machine, often shortened to grinder, is a machine tool used for grinding. Metal Cutting, Grinding Brushing Accessories | Bosch .

simple grinding machine parts

Grinding machines remove small chips from metal parts that are brought into contact with a rotating abrasive wheel called a grinding wheel or an abrasive belt. Grinding is the most accurate of all of the basic machining processes.

Centerless Grinding: Not Magic! : Modern Machine Shop

Dec 15, 2000· On traditional OD machines, the work is held between centers or chucked and rotated against the faster spinning grinding wheel by an external motor usually located in a workhead. Unlike centertype or chuckertype grinding, parts made using a centerless process do not require center holes, drivers or workhead fixtures.

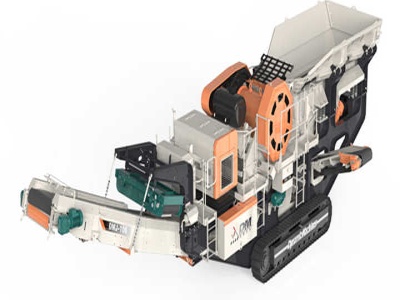

Used Centerless Grinding Machines | Centerless Grinding ...

Application of Centerless Grinding Machines. Centerless grinders have been successfully applied to manufacture a variety of parts ranging from hypodermic needles to bowling balls. The principles of the centerless grinding process remain the same regardless of the work piece to be ground. Centreless grinding machines,...

introduction to grinding machine and its parts

Parts for Grinding Machine manufacturers are recommended by TAMI and have HD videos and ecatalogs online. introduction to grinding machine bindassholidaysin. introduction to grinding machine and parts Introduction to grinding machine and its parts; Introduction to .

COST BASIS OF GRINDING MACHINE VS. MACHINING .

SUMMARY. Grinding machines and metal cutting machines are both used for the manufacture of finished products. This project is focused on the functions of the parts used in the makeup of grinding machines and metal cutting machines. The project was proposed as an investigation of the high price of grinding machines.

Basic Theory Grinding Machine

Sets up and operates machine tools, such as lathes, milling machine, shaper, and grinder, to machine parts, and verifies conformance of machined parts to specifications. Lifts machined parts manually or using hoist, and positions and secures parts on surface plate or worktable, using devices, such as vises, V‑blocks, and angle plates.

Types and Uses of a Grinding Machine | Bhavya Machine Tools

Oct 19, 2012· A cylindrical grinding machine may have multiple grinding wheels. Here the work piece is rotated and fed through the wheels to form a cylinder. It is widely utilized to manufacture accurate objects like tubes, rods, bushings, bearings, and other parts. An efficient surface grinder may be manually operated or CNC controlled.

Basic Machine Technology 10 Part Series

Basic Machine Technology: Sharpening Drill Bits by Hand or the Drill Press Teaches students how to use a pedestal grinder and a drill point grinding machine to sharpen drill bits accurately. Basic Machine Technology: Drill Presses Sensitive amp; Radial Arm Identifies the basic parts of the sensitive and radial arm drill presses and their functions.

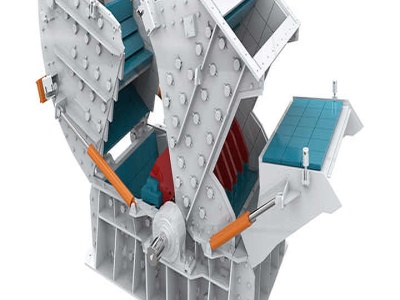

TYPES OF GRINDING MACHINES – Cad cam Engineering .

TYPES OF GRINDING MACHINES. Parts to be ground are mounted on a rotary table and run under the wheel. The table may also be tilted to provide special grinding geometry, such as hollow grinding of the sides of a circular saw. Type III The type III surface grinder has a vertical spindle, and the side (also called the grinding face)...

grinding machine parts and functions

parts and function of grinding machine Parts for Grinding Machine manufacturers offer high quality Parts for Grinding ... The best description I have seen of sewing machine parts .

Basics of centerless grinding | Cutting Tool Engineering

Dec 01, 2016· Dual grinding machines deliver a twostep process that combines centerless grinding with grinding between centers, alleviating concentricity concerns. In the Zone. Regardless of machine design, the workpiece is guided by its outer surface during centerless grinding. Because of this, roundness can be a concern, especially lobing and triangulation.

MACHINE TOOLS Yıldız Teknik Üniversitesi

machines, grinding machines, gear cutter machines, super finish machines. 3. Recommended Books In English, ... Structure of the Machine Tools The machine tool structure includes a body, which carries and accommodates all other machine parts. The.

Centre Grinding Machines

se our vertical Centre Grinding Machines quality of the types ZS 102/201 in the range of approx. 0,001 mm. The Centre Grinding Machine complies with the CEstandards. Technical Machine Data of Henninger Centre Grinding Machine ZS 2000 Workpiece length max. 800 mm 1200 mm Weight of the workpiece max. 20 kg 50 kg

Grinding Machine Types Of Parts Functions YouTube

May 09, 2019· This is a compact CNC machine for external grinding of small components in...Machining OperationsImage of grinding machine. Grinding machines can produce parts of the identical size, shape, and ...

Shaper machine: Main Parts and Working mech4study

May 08, 2016· Today we will learn about shaper machine parts and its working. It is commonly used to produce flat surface, grooves, slots etc. The work piece is hold by a adjustable tool post in shaper machine. A single point cutting tool is in reciprocating motion rub the work piece and cut unwanted metal from it in form of chips. It consist many important ...

Walter Grinder Grinding Inserts | Helitronic Basic

With its 5 CNC axes, the HELITRONIC BASIC sharpens and grinds a wide spectrum of precision tools for metal and wood with the highest precision and quality. Short setup and idle times produce economic results from a batch size of 1 even in multiple shift operation with low staffing levels.

Cylindrical grinder Wikipedia

History. It is important to note that Brown Sharpe cannot be given sole credit of pioneering advances in cylindrical grinding. A man in Waltham, Massachusetts, Ambrose Webster had created a small grinding machine in 1860 that contained all of the improvements Brown .

CNC grinding

Internal grinding of flange parts or spindles up to 1,300 mm long – for the new Studer S141, both are no problem at all. The machine, first unveiled in Autumn of 2014, is the vanguard of a new machine platform for universal internal grinding, to be followed by additional sizes of models at the EMO 2015.

cost basic of grinding machine vs machining machine ...

cost basic of grinding machine vs machining machine offers 3035 industrial pepper grinding machine products. About 48% of these are other food processing machinery, 13% are grinding equipment, and 1% are grinding machines. . automatic dry black pepper powder milling machinery good price for sale ..

BIRO GRINDER PARTS LIST STAINLESS MODEL 6642

Be sure line voltage is up to specification. (C) Electrical connections to be in accordance with safety codes and National Electrical Code. (D) Rated voltage of the unit shall be identical with full supply voltage. (E) Voltage drop on the supply line shall not exceed 10% of full supply voltage.

Surface Grinder Improves Machine Tool Components: Modern ...

Aug 09, 2018· The machine then automatically moves the wheel to inch above the part surface and resumes the grinding operation without operator intervention. Teach feature. Operators can use the grinding wheel to "teach" the machine and set the grinding envelope for new parts.

Grinding Wheel Use Precautions Dos and Don'ts for Safe ...

1 Handle and store wheels in a careful manner. Observe the 3 basic rules of "no rolling, no dropping, and no contact with other objects". Store wheels on a shelf or storage rack in a dry place. 2 If the grinding wheel is marked with a service limit, be sure to use it only within the service limit period.

DIAGRAM OF LATHE MACHINE American Machine Tools

DIAGRAM OF LATHE MACHINE. Explanation of the standard components of most lathes: • Bed: Usually made of cast iron. Provides a heavy rigid frame on which all the main components are mounted. • Ways: Inner and outer guide rails that are precision machined parallel to assure accuracy of movement.

Latest Posts

- المرجعية الذهب مطحنة التفتيش شكل

- مصنع كسارة الفك الكلي

- يا جويل كسارة للخرسانة إذا كان على المسار أوه

- مصنع كسارة متنقل للتأجير في مصر

- معلمة كسارة الحجر هيماشال

- المصنعين الحزام الناقل في ليبيا

- مطحنة كهربائية في مصر

- عملية سحق الباريت في مصر

- تقرير مشروع تصنيع بلوك الخرسانة

- مُصنع آلات طحن

- ناقل تصريف متعدد

- المغرب المحمولة سحق النبات

- حجر صغير آلة الصانع كسارة في ولاية غوجارات

- مطحنة الكرة لمحطة الطاقة

- الفصل المغناطيسي scheelite من الكوارتز

- equipment quarry crusher equipment quarry line

- gold ore crusher provider in indonessia

- river gravel report

- concrete crushing colorado html

- slate processing line supplier

- laboratory ore iports of stainless steel

- chrome recovery companies in south africa

- china professiona used stone crushing equipment price

- mining crushers spares india

- zealand floating trommel

- price for mini grinding mills in south africa

- rsa non woven fabric manufacturer in solan

- copper pyrites bornite chalcocite azurite zigueline jaw crusher

- antimony ore separation machinery

- gravel sand washing machines