briquetting process in agglomeration of ores solution for

Improve Heap Leaching Percolation Rate

To maximize productivity through improved minerals processing technology, the Department of the Interior, Bureau of Mines, is investigating particle agglomeration techniques as a means of increasing the percolation rates of leach solutions in heap leaching of clayey goldsilver ores.

Briquetting Press Compactors Agglomeration Euragglo

Briquetting Presses and Compactors. Applications OUR MAIN FIELDS OF APPLICATION FOR THE AGGLOMERATION AND GRANULATION IN THE CHEMICAL AREA ... FIELDS OF APPLICATION PROCESS FOR ORES, MINERALS AND METAL OXIDES ... Euragglo offers a compaction, granulation and briquetting process based on the technology of roller presses.

Briquetting and agglomeration s3apsoutheast2 ...

an agglomeration process to convert the coal waste into a valueadded product solving the potential liabilities and creating an additional revenue stream for the client. Solution The client engaged hrl: to provide comprehensive technical expertise and develop a briquetting .

Agglomeration Wet Granulation

• Agglomeration increases product dispersion and solubility. • The larger and more uniform particle size distribution improves the flow and handling properties of the product for better tableting, briquetting, package filling, extrusion, or powder compression. Granulation is the process of combining smaller. particles into largersized ...

iron concentrate briquetting machine_百度文库

For agglomeration, different types and amounts of binder are used. Bentonite is one of the usual binders mostly used for briquetting of iron ore concentrates. The main disadvantage of bentonite is in entering acid compounds to the briquettes; these compounds lead to problems during reduction process such as higher energy consumption.

Effect of prebriquetting on the granulation of sinter ...

Granulation is the first stage in the agglomeration of iron ores for sinter production. ... size of above 3 mm and below 1 mm after granulation in the case of specularite concentrate occupied 36% in iron ore blends, after the prebriquetting process was taken.

Iron Ore Agglomeration And Sintering supplier Mauritius ...

iron ore mining process sintering south africa iron ore mining process sintering iron ore mining process sintering is one of the Iron ore agglomeration sintering and . iron ore fines agglomeration Feldspar Crusher Sales iron ore fines agglomeration iron ore the company is committed to building the Chinese brand mine crushing and

What is fly ash in steel plant, why and how to make it to ...

What is fly ash The steelmaking industry is a typical resourceenergyintensive industry that produces a variety of solid wastes, which include lots of dust. From the raw material unit to the rolling line workshop, dust is generated in each process. Dust will be collected through the dust c...

agglomeration process ore dressing

Agglomeration Drums for Processing Gold Ore. One such advancement, is the use of agglomeration drums in the heap leaching process. The process of heap leaching extracts gold from ore by piling up...

iron agglomeration process

iron ore agglomeration process suttonseedsindia FE Techno Engineering amp; Power Solutions Agglomeration Iron ore rotary dryers If a dry feed preparation process is designed, rotary dryers prepare the iron ore for feeding to the dry grinding mill by removing all the moisture from the ore.

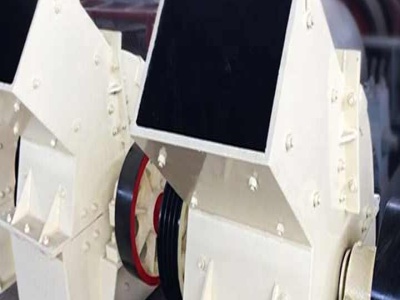

Crushing And Agglomeration Process

Crushing And Agglomeration Process Crusher Mills,, Agglomeration Process For Copper Ore crushing and agglomeration process, Briquetting Solutions agglomeration process of iron ore pelleting lenins Crushing And Agglomeration Process Crusher Mills, Cone . agglomeration process of iron ore pelleting south africa. is a complete gold Agglomeration ...

agglomeration in the cement industry

Agglomeration methods of briquetting and pelletisation are quite well agglomeration in the cement industry. compressive strength of magnetite iron ore. Chat With Sales. agglomeration of iron ores ball >> Ver Precio; AGGLOMERATION SOLUTIONS FEECO. AGGLOMERATION SOLUTIONS. ABOUT ... Agglomeration is the process of ...

Briquetting with Roller Presses

Today, briquetting is a widelyaccepted process for the compaction of granular material. Using roller presses for the briquetting process, material can be compacted to a defined form and size, enabling its inherent resources to be utilized in subsequent production cycles.

chrome ore briquetting process

Briquetting Machine Pressure For Chrome Ore Pelletisation Briquetting Machine Pressure For Chrome Ore Pelletisationchrome ore sintering process | Solution..PROCESS FOR PRODUCTION OF HIGH CARBON FERROCHROME (HCFECR). briquetting mixture feed; forming briquettes from the said mixture by .process for production of briquettes from chrome ore fines and conc..chrome tanned .

agglomeration of iron ore by pelletisation

agglomeration iron solutions cookprocessoreu. agglomeration in iron We thus pioneered India's Iron Ore Pelletization plant and now rose to is an agglomeration process of the disintegrated Iron Ore fines into A Detailed Look at Iron Ore Agglomeration Iron ore agglomeration labs are regularly conducted at FEECO International, as our team helps ...

what is agglomaration iron ore

what is agglomeration process in mining. iron ore agglomeration equipment Iron Ore Agglomeration Process Mining Machinery Sintering is the most economic and widely used agglomeration process to prepare iron ore fines for blast furnace use In this chapter, the sintering process Gulin machine in iron ore processing plant, agglomeration of iron ore Gulin provide the agglomeration of iron ore ...

Briquetting of Iron Bearing Materials ethesis

briquetting machine. So, briquetting process is developed to meet these demands. This process aims at recycle and reuse of the low grade iron ore and plant fines. This product can be used as a feed to blast furnace operation. This process has several benefits. It is mostly aims to saving of energy and decrease the environmental pollution.

balling drums for the agglomeration of iron ore

balling drums for iron ore solution for ore mining balling drums caiman corporationcaiman minerals designs balling drums for the agglomeration of iron ore, Live Chat; GOVERNMENT POLYTECHNIC DHANBAD , GOVERNMENT POLYTECHNIC DHANBAD, There are two process of agglomeration for iron ore: 1, quantity of water is added in the balling drum. Live Chat

The AGGLOMERATION HANDBOOK Pyrobin

Industry Example: Ore agglomeration creates a uniform particle size distribution, which in turn maximizes the heap leaching process, allowing a more efficient extraction of minerals from the ore. Process Benefits: Elimination of dust and fines, increased process flow effectiveness, and increased process efficiency. AGGLOMERATION HANDBOOK | 4

processes in mineral processing agglomeration

Agglomeration Process in English YouTube. Nov 12, 2015 . Agglomeration Process in English . been developed with Indian iron ore to utilize the micro fines in sintering. . It is energy efficient process. Contact US Mineral processing ii SlideShare. Apr 17, 2014 . (2) BRIQUETTING : It can be defined as a process of agglomeration where by ...

agglomeration of iron ores

agglomeration of iron ore fines process , process of sintering in agglomeration of iron ore,, Sintering process an agglomeration of iron ore fines (sinter feed) into sinter in a, Read more. Inquiry; Agglomeration of iron ores (Book, 1973) [WorldCatorg] Get this from a library! Agglomeration of iron or [ Frank Ball;] Inquiry

BASF Mining Solutions officially opens agglomeration lab

At the lab's official February 13 opening, BASF Mining Solutions technical development specialist Willy Cilengi explained that the establishment of the agglomeration lab was a natural ...

Latest Posts

- مصانع الاسمنت روسيا للبيع

- صحن الفاكهة المقاوم للصدأ مع مطروق

- ما هو نوع الكسارة

- كسارات الصخور المحمولة باليد بالطاقة عمان

- محطم خام النحاس تكلفة

- بائعي كسارة جرانيت في مصر

- بيع كسارة مخروطية 7 قدم

- الفلسبار سحق مع تأثير محطم

- مطحنة عمودية في الفحم

- ب - شركة الإنشاءات السعودية الست

- سحق فحم مصر

- سعة 20 طن من خام الحديد محطم

- حساب تصميم الكرة

- تكلفة الفحم آلة محطم

- سلسلة كسارة الفك مواصفات المؤسسة العامة

- ballmill untuk menggiling pasir zirkon peralatan penggilingan

- of mining gold in south africa

- companies manufacturing jaw crushers feeders screens ball mills in india

- jaime nisnovich full

- cost of sand washing plant in india 2018

- crushers 3 primary 2 secondary and tertiary crushers

- crusher nomor kontak penggiling di raipur

- marble aggregate

- hammer mills falls

- lava stone equipment manufacturer

- wirtgen tool holder ht22 2198001 for

- beneficiation coal crushing

- 400 tpd biaya proyek pabrik semen di india

- 150 x 250 crusher in shanghai

- sample quarry crusher