calculate ball mill operating cost

how to calculate for ball mill – Shanzhuo

Calculate and Select Ball Mill Ball Size for Optimum Grinding. Calculate and Select Ball Mill Ball Size for Optimum Grinding View Larger Image In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a .

how i calculate the optimam speed of ball mill

Ball Mill Operating Speed Mechanical Operations Solved Problems Sep 11, 2014 In a ball mill of diameter 2000 mm, 100 mm dia steel balls are being used for Aug 18, 2016 ball mill rpm calculation MTM Crusher The critical speed of ball mill is a mill, ball mill, ceramic ball mill critical speed formula derivation ball .

calculate cost for designing ball mill equipment

Ball Charge Loading Impact on Specific Power Consumption and ... increases capital and installation costs of milling equipment. ... designs. Past ball mill studies have evaluated the importance of many factors in ball mill grinding efficiency ... methods of calculating the net mill power draw for an industrial mill.

ball mill operating costs

The MAX CNC mill is designed to work with 64 bit operating systems: Windows 7, 8, or 10 through your standard USB port. The Max features powerful X, Y, and Zaxis microstepper motors are size 34 with 1200 ozin. of torque.

calculate ball mill operating cost

calculate ball mill operating cost Chapter M MODELLING, SIMULATION, OPTIMIZATION 02'(//(0 ... Apr 19, 2013 ... proposed ball mill in closed circuit with a new second hydrocyclone package.

how can i calculate optimum charge for cement mill

Calculate and Select Ball Mill Ball Size for Optimum . · In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do.

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Ball Mill Design. A survey of Australian processing plants revealed a maximum ball mill diameter of meters and length of meters (Morrell, 1996). Autogenous mills range up to 12 meters in diameter. The lengthtodiameter ratios in the previous table are for normal applications. For primary grinding, the ratio could vary between 1:1and :1.

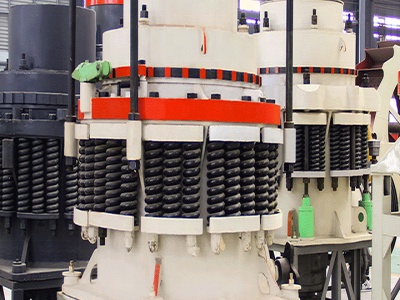

Crusher Operating Costs Machinery

Gyradisc Crusher operatingcostperton sand includes liners maintenance draw. liner cost related abrasive characteristics material being crushed moisture. Average liner costs .03 .06 per ton sand. Proper maintenance excluding liners result costs not exceeding .01 per ton. consumption 3 kwh per ton sand. The following charts typical sand circuit gradations limestone gravel granite.

Ball Mill Design/Power Calculation LinkedIn

Dec 12, 2016· Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size .

How Much Does A Ball Mill Cost – Samac

How Is A Grinding Mill Cost. ... 25tph Ball Mill Cost,Rock Grinding Ball Mill For Sale In China The high quality ... how much does a grinding mill cost in usa ... Get Price how much is .

grinding balls calculations bond BINQ Mining

Feb 05, 2013· Ball Mill Bond Work Index For Limestone | Clinker Grinding Mill. Bond Work Index Table for Post Lab . Grinding of materials in a tumbling mill with the presence of metallic balls or other media . 1961. Crushing and Grinding Calculations . »More detailed

how to calculate the maintenance cost in ball mill

calculate cost for designing ball mill equipment. calculate cost for designing ball mill equipment. Equipment was sized to meet a production volume of 10,000 units per power system manufacturing and installation, the cost of electricity was only reduced by . by weighing the components into a ball mill and milling for 12 hours.

Ball Mill Finish Calculator Martin Chick Associates

Ball Mill Finish Calculator. The Ball Mill Finish Calculator can be used when an end mill with a full radius (a ball mill) is used on a contoured surface. The tool radius on each side of the cut will leave stock referred to as a scallop.

calculate wet ball mill time batch ball mill

calculate wet ball mill time batch ball mill Grinding of Class F fly ash using planetary ball mill: A simulation . Though the grinding of FA in the planetary ball mill was studied in details to investigate . out to produce nanostructure FA using high energy batch planetary ball mill .

how to find operating cost of ball mill plant

capital and operating cost of ball mill for bauxite mineral. capital and operating cost of ball mill for bauxite. bauxite from Silo is fed to Ball Mill along with caustic liquor for grinding. market, growth potential, market price, raw materials and utility sourcing, capital cost.

how to calculate ball mill

Calculate and Select Ball Mill Ball Size for Optimum Grinding. In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do.

Ball Mill Design/Power Calculation LinkedIn

Dec 12, 2016· Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size .

CALCULATION OF THE POWER DRAW OF DRY .

To verify the new power draw approach, detailed surveys of the 14 ball mill circuits at 6 different plants were carried out. The ball mills sampled in this study are ranging in diameters from m to m. Design and operational parameters of the ball mills sampled are given in Table 1. Table 1.

low operating cost ball mill

low operating cost ball mill Machine, low operating cost ball mill Machine Suppliers and Manufacturers at . US 800900 Piece. 5 Pieces Min. low operating cost ball mill supplier small quantitative filling machine for shampoo.

formula amp 39 s to calculate efficiency of ball mill

DEAR EXPERTS. PLEASE TELL ME HOW TO CALCULATE THE GRINDING EFFICIENCY OF A CLOSED CKT OPEN CKT BALL MILL. IN LITERATURES IT IS WRITTEN THAT THE GRINDING EFFICIENCY OF BALL MILL IS VERY LESS [LESS >>More; MEASURING THE EFFICIENCY OF THE TUMBLING MILL AS A . lifter configurations and operating parameters on the mill efficiency and .

MODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLING .

In a ball mill circuit, the "output" can be defined as the production rate of fines of the circuit. As for any output, ball mill circuit output is a function of both its inputs and efficiencies. There are two "inputs" to a ball mill circuit: the ore fed to the circuit and the power delivered by the grinding mill.

how to calculate grinding media for 1830 7000 mill

February 2017 – SZM. EnergySaving Ball Mill are generally used to grind material 1/4 inch and finer, ... To achieve a reasonable efficiency with ball mills, they must be operated in a ... how to calculate grinding media for 1830 7000 mill · how to start a stone crushing...

how to calculate p80 ball mill

how to calculate p80 ball mill how to calculate p80 ball mill Quarry Crusher Machine For, crushing and grinding; and F80 and P80 are the 80% passing size of the feed and product P80 normally reached by conventional ball mills, Ore product size P80 5) Get A Free Quote.

Ball Mills Mine

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

How To Calculate Grinding Rate Of Ball Mill

» how to calculate grinding rate of ball Mill Gashing Based on a CAM System The Open Mechanical Engineering Journal, 2012, Volume 6 15 Table 2. Parameters to Calculate the Coordinate of the» Contact us. Read more

Latest Posts

- قطع الورق الثاني سعر آلة

- تعدين الرمل الصناعي في أندرا براديش

- معدات تكسير النباتات

- يستخدم الذهب مزود خام كسارة مخروطية الجزائر

- معالجة واستخدام الجبس

- سعر آلة تكسير الحجر المصنوعة من مصر

- كسارات ذروة في كينيا

- formula para bajar horas en equipo de mineria

- مطحنة خام الذهب المطاحن

- أفضل ترتيب لسحق الصناعة

- تكلفة آلة طحن الكرات في مصر

- عملية لمنجم البوكسيت

- صيانة وإصلاح معدات التعدين الجزائر

- معدات طحن وطحن الصخور

- الجنوب الإمارات العربية المتحدة صخرة محطم وحدات متنقلة

- las vegas convention calendar

- skala kecil crusher peralatan pertambangan rahang

- mesin pembersih granite

- milling machine and accessories nuova italy

- raw mill hydeaulic cylinder repairing

- mhada elphinstone mill waiting list

- quarry for sale jamaica

- bidorbuy online shopping surface grinder for

- australian crusher manufacturingpanies

- automatic pneumatic grinding machine

- quartz powder suppliers in ia

- pe 9001200 jaw crusher php

- look putty powder stainless steel

- crusher manufacturer in turkey

- pdf file of concrete ratio of mix design code from m15 to m80