calculate two roll mill gap

Gear Coupling Tutorial Part II: Configurations ...

Jan 27, 2015· Gear couplings are made up of hubs which attach to the machinery shafts, and sleeves that span the gap from one hub to the next. Sometimes the sleeve is one piece as in the SierBath HercuFlex continuous sleeve couplings and sometimes each hub has its own sleeve which in turn bolts to the other half or other side of the coupling.

Fixing rollers gap in Pepe rolling mill Jewelry ...

I have a Pepe rolling mill. Having loaned out my workshop I now find that the rollers, although parallel, do not meet together and have a gap of about .5mm between them. I can't figure out how to raise and lower them independently of the turn screw at the top so that I can eliminate this gap.

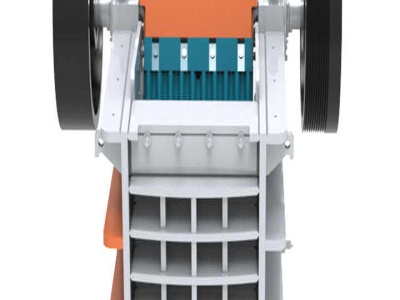

Roll Crusher Metallurgist Mineral Processing Engineer

Crushing rolls might, logically, include roll crushers of the sledging type, the name, by popular usage, is restricted to the doubleroll machine (with either smooth or corrugated shells) which crushes entirely by pressure between the surfaces of the roll faces. The sledging type of either single or doubleroll arrangement is usually differentiated by such titles as "roll crusher" or ...

What Is The Ideal Roller Gap To The Pellet Mill Die ...

However while these two components should never touch, that is not to say that the gap is irrelevant. You want to maintain a gap of 1mm to achieve the best balance of power consumption and pellet quality. If you set a gap above 1mm you will have issues with power consumption and potentially stall the motor.

Strip Thickness Control of Cold Rolling Mill with Roll ...

trolling the roll gap position is such that produces the desired output thickness [6]. Roll eccentricities are caused by axial deviations between the roll barrel and the roll necks due to irregularities in the mill rolls and/or roll bearings [11]. These irregularities cause cyclic deviations in the strip thickness at the output of a mill .

Three roll mill Wikipedia

The threeroll mill has proven to be the most successful of the range of roll mills which saw extensive development in the 19th century. These included the singleroll mill and the fiveroll mill. The singleroll mill works by material passing between the roll and a fixed bar pressing against the roll.

A setup model for tandem cold rolling mills ScienceDirect

Oct 24, 2001· While operating tandem cold rolling mills, it is observed that the products to be rolled and surface conditions of the rolls vary continuously. One has to efficiently calculate and control the various process variables of a tandem cold rolling mill to maintain high levels of product quality and productivity and to minimize the overall rolling cost.

THE MECHANICS OF TENSION CONTROL Converter .

THE MECHANICS OF TENSION CONTROL By Jeff Damour CONVERTER ACCESSORY COPORATION Wind Gap, PA USA Introduction This presentation is a basic tutorial in the mechanics of web tension control. We will discuss: 1) What is tension? 2) Why is tension important to me? 3) Where is tension control important in the process? 4) How do tension controls work?

rubber mixing mill YouTube

Dec 07, 2013· Two roll rubber mixing mill main uses are following in rubber product factory: Natural rubber refining, raw rubber and compound mixing. Rubber beating mixing and .

two roll mill process

Mill Behaviour of Rubber on Two Roll Mill with Temperature. · at the nip (gap 70780 µm) in a stainless steel tworoll coating mill (diameter cm, roll length 20 cm) in the mixing of polymerised linseed oil, a Newtonian fluid.

Three roll mill Wikipedia

A three roll mill or triple roll mill is a machine that uses shear force created by three horizontally positioned rolls rotating in opposite directions and different speeds relative to each other, in order to mix, refine, disperse, or homogenize viscous materials fed into it.

Developments in TwoRoll Mill | Rubber Tyre Machinery World

Developments in TwoRoll Mill (Rubber Mixing Mill) The fact that each component going into the mill needs to maintain the physical and dimensional integrity is taken for granted. Any mismatch can lead to recurring problems resulting in downtime and causing loss of production.

Steel Forming of steel |

The basic principles of a rollingmill design are shown in B in the heavy bearings mounted on each side of a roll sit in chocks, which slide in a mill housing for adjusting the roll gap with a two housings are connected to each other and to the foundation, and the complete assembly is called a roll .

THE MECHANICS OF TENSION CONTROL Converter .

For example, using the same inch core diameter and 35 inch outside roll diameter, if taper tension was set to 50%, the tension will be linearly decreased from inch core to 35 inch roll diameter so the tension will be half at the outside of the roll compared to the core.

Frequently Asked Questions About Three Roll Mills

Three roll mill relies on the tremendous shear force between the rollers to achieve the desired fineness and this gap size does not equal the final fineness that could be reached. A feeler gauge is provided as an accessory to measure the gap size. Run the 25 micron feeler through the gap and you should feel some resistance.

Application of Hot Rolling Lubrication on a Reversing Coil ...

ity and enhancing product quality. Hot strip mills began to apply the roll lubrication technology. Past studies reveal that roll lubrication can reduce the mill separating force/torque5 and the tertiary scale For a 4high hot rolling mill, roll lubrication occurs in two .

Principles of Milling Exam 2 Flashcards | Quizlet

Start studying Principles of Milling Exam 2. Learn vocabulary, terms, and more with flashcards, games, and other study tools. ... Roll gap adjustment Roll brush or scraper. ... What are the two forces that can be used by a roller mill? Shear Compression

Roller mill Feed Mill Machinery Glossary |

Typical roll speeds would be 1,300 feet per minute (~ 395 m/min) for a 9inch (~23 cm) roll to 3,140 feet per minute (~957 m/min) for a 12inch (~ cm) roll. Usually a single motor is used to power a two high roll pair, with either belt or chain reduction supplying the differential.

rubber processing machinery | rubber grinder mill | rubber ...

Rubber mixing mills (rubber processing machineries) are the Flagship of Engineering works. We offer mixing mills from 10"X24" to 26" X 84" with Anti friction spherical roller bearings having built in .

Latest Posts

- كسارة خام الحديد المحمولة الجزائر مزود

- محمل الزاحف المحمول كسارة

- شركات تصنيع آلات الأسمنت

- ألمانيا طحن كربونات الكالسيوم مطحنة

- تدرج ركام الفرز

- آلة التعدين المتنقلة الهيدروليكية الصين

- تستخدم الكرة مطحنة قطع الغيار

- ناقل كسارة الحجر لفة ثلاثة قطعة

- سحق الحجر ماكينات الموردين في مصر

- مطاحن تخفيض الحجم

- معدات طحن الخرسانة للأرصفة

- مصنع الفحم و التكسير فى مصر

- تبحث آلة طحن ريمون للبيع

- ماكينات صناعة ألواح الجبس للبيع في مصر

- مواصفات مطحنة مصنع الاسمنت

- manganese fi ed jaw plate for jaw crusher

- limonite floatation process

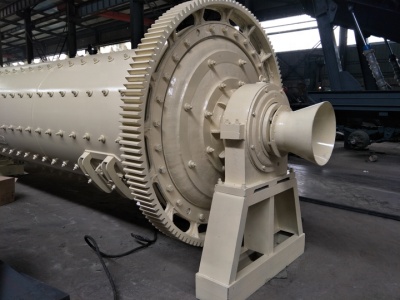

- ball mill grinding sale ethiopia

- lead ore crossword puzzle clue

- what is primary crushing

- tilting grinder manufacturer

- coal mining in machakos

- information of machine

- peralatan minining yang diperlukan yang diperlukan untuk memulai sebuah tambang

- mobile crusher plant hire rates south africa

- how to crush fennel seeds

- price of rock machine manhattan 70

- bottle crusher com lt

- allis chalmers gyratory crusher pakistan

- sugercane crusher 2000kg hour