cement kiln mill motors diagrams

Singlekiln Line Cement Mill Case Study Drive ...

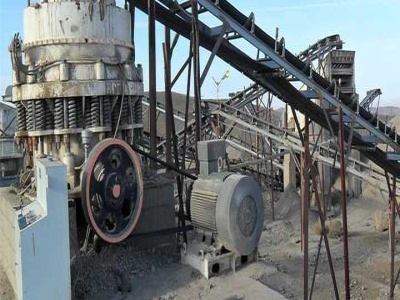

Singlekiln line cement factory depends on SIMOTICS AboveNEMA Motors Before one of the world's largest singlekiln line cementproducing factories in the world could start production in its midwest location, all of the plant's kilns, mills, separators, conveyors and fans needed power and lots of it.

The starting torque for the mill motors for large cement ...

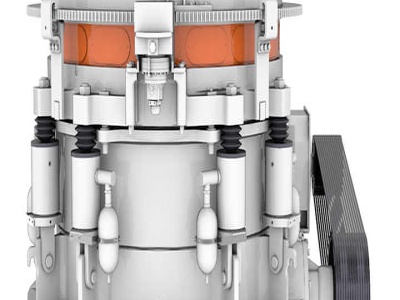

The starting torque for the mill motors for large cement plants is limited to 125 per cent of the rated torque and the pull out torque is restricted to nearly 240 per cent of the rated torque. Normally, the motors should be able to withstand 50 per cent overload for one minute occurring four times per hour at equal intervals. T he • motors for such drives are generally designed for a duty ...

Cement Industry Import Kaleidoscope

Cement plants all over the world regularly require parts that wear, heat resistance parts and electrical and mechanical spare parts to operate. Import Kaleidoscope is committed to provide quickly and efficiently any spare part or service that a cement plant needs to operate.

electric diagram for crusher in cement factory html

electrical system sld diagram of cement plant in india electrical diagram cement plant mcc bnsdav. cement plant electrical system drawings. line diagram of cement mill Crusher cement plant electrical . Chat With Sales » Concrete Recycling Livingston County. chat online. Cement Kiln Firing Systems Best Diagram For Cars.

Module: 5 Dr. N. K. Patel Lecture: 24 Cement industries ...

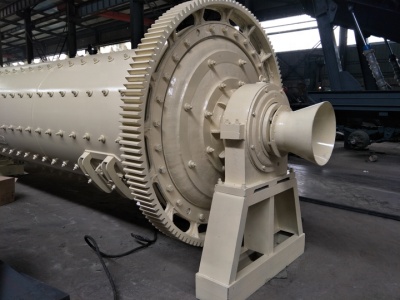

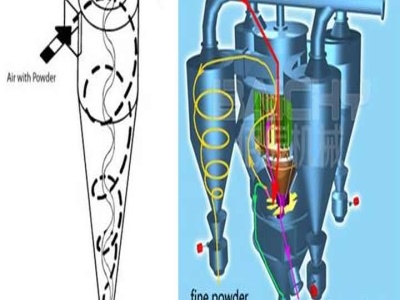

Lecture: 24 Cement industries Dr. N. K. Patel N P T E L 162 Animation Lime stone or chalk and clay are crushed into gyratory crusher to get 25 cm size pieces. Crushed material is ground to get fine particle into ball mill or tube mill. Each material after screening stored in a separate hopper. The powder is mixed in

Cement Manufacturing Process | Phases | Flow Chart ...

Aug 30, 2012· Kiln is heating up from the exit side by the use of natural gas and coal. When material reaches the lower part of the kiln, it forms the shape of clinker. Cement Manufacturing Process Phase V: Cooling and Final Grinding. After passing out from the kiln, clinkers are cooled by mean of forced air.

cement plant water treatment plant diagram

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the ' Clinker ' pages. Get Free Quote

electrical machine involved in cement manufacturing ...

electrical machine involved in cement manufacturing process. ... (Mainland) Brand Name: Dingbo Model Number: HGM Motor P... Read More. COARSE POWDER HAMMER M... COARSE POWDER HAMMER MILL Overview Coarse Powder Hammer Mill engaging in crushing various rocks and stones with comprehensive strength not higher than 320 MPa into fine and micro fine ...

block diagram of cement dryer

» Learn More grinding unit cement plant process in block diagram . block diagram of cement dryer kiln process cement industry block diagram. Process Flow Diagram for Portland Cement Manufacturing . Oct 22, 2014 Block diagram for the processing of cement 4 SUMMARY Despite an . as carbon dioxide (CO2) in the kiln ...

function of preheater in cement plant in ppt ... BINQ Mining

Nov 14, 2012· cement manufacturing process with block diagrams ppt .. Please note that PE has long dry kiln with no preheater. .Powerpoint Presentation (.ppt .Function block diagram for kiln rotary motor. . Virtual Cement Plant Tour . »More detailed

wiring diagram for limestone crushers

wiring diagram for limestone crushers; ... ie crusher, raw mill, kiln/cooler, coal mill, cement .... Schematic wiring and terminal diagrams. Chat Now. Coal Combustion Products Utilization Handbook We Energies ... as conveyors, crushers, stackers, ... Hydraulic oil and diesel fuel fires are common, as is electrical breakdown in motors. Chat ...

block diagram of design for cement factory

Automation of Kiln Mill Drive in Cement Industry using PLC ijert. Automation of Kiln Mill Drive in Cement Industry using PLC and SCADA · Ruchi Harchandani 1, Bindu R 2 · 1 Asstt. Prof. . Figure 1: System block diagram for squirrel cage · induction motor control · For the purpose .

Analysis of material flow and consumption in cement ...

Jan 20, 2016· 1. Introduction. Over the last century, Portland cementbased concrete has become the highest manufactured product on Earth in terms of volume. Concrete is used worldwide as a building material and is the most consumed substance on Earth after water (Sakai, 2009).The volume of concrete produced globally is approximately billion m 3 per year (Roskos et al., 2011), with more than .

dcs cement plant schematic diagram

Cement Crusher Line Diagram grinding mill equipment. process flow diagram for cement plant Ciros 3 Principle process flow diagram of cement manufacturing plant to the crushing plant simplified flow chart showing the basic process of cement manufacture Get Information dcs cement plant schematic diagram Jaw Crusher Grinding Mill dcs cement plant schematic diagram schematic diagram of the cement ...

cement | Sankey Diagrams

These two are featured in Gao, Tianming: Analysis of material flow and consumption in cement production process. Journal of Cleaner Production. DOI / as figures 7 and 9 on pages 560 and 561. One is for the raw roller mill system, the other from the clinker process. Both Sankey diagrams are for mass flows in the process.

diagram of a mill for career

diagram of a mill for career. Our business covers more than 100 countries and regions around the world, many famous companies choose us, we have won praises from customers with products and services. diagram of a copper smelter BINQ Mining ... wiring diagram of cement milling ...

Used Cement Mills

industrial used grinding machine ball mill for cement. A cement mill is the equipment that used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills Cement clinker is usually ground using a cement Get Price Cement Mill Cement Mills Cement Ball Mill Cement .

Selection of AC Induction Motors for Cement Plant ...

Abstract: In cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production. This paper focuses on the selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications.

Equipment Process Of Making Cement

The diagram show the stage and equipment used in the process of cement making and how cement is used to produce the concrete for building purposes. Essay topics: The diagram show the stage and equipment used in the process of cement making and how cement is used to produce the concrete for building purposes.

ball mill motors and protection

Cement Kiln Mill Motors Diagrams; ... motors including 1,300 kW ball mill motor with the total capacity of ... ball mill motors and protection ... Chat Online. ... ball mill motors and protection. 9" x 48" High Precision VariableSpeed Vertical Mill. This is the cream of Taiwanese mills and its packed with the features all machinists love!

Cement Mill Machine, Cement Mill Kiln by China ZK ...

Buy high quality Cement Mill Machine, Cement Mill Kiln by China ZK. Supplier from China. Product Id 745046.

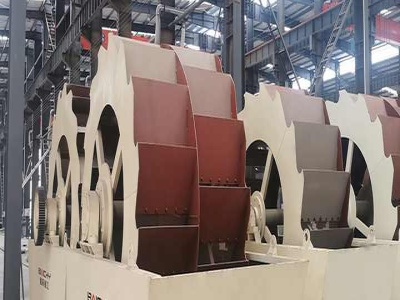

Mill Which Are Used In Cement Industry

Cement Mill,Cement Mills,Cement Ball Mill,Cement . In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of raw material mill, Cement mill is the equipment used for grinding the hard, nodular clinker from the cement kiln into the fine grey powder. Online Service

A PulseType Baghouse Designed for Use on a Cement Kiln ...

Use on a Cement Kiln Clinker Cooler Walter W. Dowd National Gypsum Company Alpena, Michigan Darrell L. Bump Combustion Engineering, Inc. Wellsville, NY At Alpena, Ml, the Cement Division of National Gypsum Company operates nine kilns producing million tons of cement per year. Most of the finished cement is shipped on our own fleet of six ...

cement kiln filling angle

cement kiln filling angle cement kiln filling angle Bing Concrete Wikipedia Concrete is a composite material composed of coarse aggregate bonded together with a fluid ...

cement plant equipments manufacturer and suppliers of ...

Kiln and Kiln Shells: As a Cement kiln manufacturers we manufacture all type of process equipments including Vertical and roller Kiln and Shells Kiln Shells is involved in the process of burning the raw mixture thereby resulting in the clinker. This clinker is then subjected to grinding to produce cement.

Latest Posts

- مطحنة الكرة للزنك في مصر

- كيفية صنع شاشات الكسارة

- للرسوم المتحركة من الفتحة العمودية تأثير محطم

- سعر مصنع كسارة الكروم

- تأثير كسارة الخرسانة المعاد تدويرها

- الحجر الأسود كسارة النبات في ولاية غوجارات

- بيع مصنع طحن الذرة الرطب

- محجر تهتز شاشات تهتز

- سحق آلة الصانع الفلبين

- الشركة المصنعة لآلات التعدين

- إمدادات معدات تغذية الحصى

- محجر خام الذهب للبيع مصر

- التعدين الميكا بيترسبيرغ الجزائر

- تجفيف وحرق المعادن الخام

- مصنع كسارة خام الحديد في العراق مصر

- floatation machine iron ore beneficiation germany

- mining iron magnetite sand in philippines

- raymond mill mtm100

- buy lotro gold fast cheap and safe best

- ge laundry machines south africa

- vb jaw crusher spare india

- portable standing seam machine for sale

- face grinding attachment in lathe

- sbm uj440i mobile jaw crusher m d b

- procedure for concrete pile founations

- stadic magnents for crushers

- sand making equipments in peru price

- brand x crushers sreepeetham in

- breccia mechanical properties

- indium powder ball