cement manufacturing process at lumshnong

Manufacturing of Cement By Dry and Wet Process

Sep 08, 2018· The cement from silos is packed by machines in bags. Each bag of cement contains 50 kg or m 3 of cement. Now let's know manufacturing of cement by the dry process. DRY PROCESS. When the available raw materials are quite hard, then this process is used . The cement by this process can be prepared by using the following operations:

PROCEEDINGS OF THE PUBLIC HEARING FOR THE PROPOSED .

OF MIS STAR CEMENT MEGHALAYA LIMITED HELD ON THE 8TH MAY 2009. An Environmental Public Hearing in respect of the proposed 5300 TPD Cement Clinker Unit with 30MW Captive Power Plant at Lumshnong, Khliehriat, Jaintia Hills District of Mis Star Cement Meghalaya Limited was held on the 8th May Hearing which commenced

cement manufacturing companies in india

Cement Manufacturing Companies in India, Indian Cement ... Started as Satna Cement factory in 1959, MP Birla Cement today, is one of the leading cement manufacturing companies in India. It is involved in the production process of the nation's best quality cement that assures strength, durability, and robust structures.

AIR POLLUTION CONTROL TECHNIQUES FOR THE CEMENT ...

AIR POLLUTION CONTROL TECHNIQUES FOR THE CEMENT MANUFACTURING INDUSTRY: A CASE STUDY FOR ZIMBABWE D. Zimwara1, L. Mugwagwa1, ... Cement Production Plant (Cement Company, Zimbabwe) ... manufacturing process then directly and indirectly gives rise to offensive smells as the dead

Penna Cement | About Penna employs the Best Cement ...

Standing tall Penna Cement is one of the best cement companies in India, considered as the Best Cement For Construction is one of the leading cement suppliers in India; Penna cement factory employs the best cement manufacturing process that ensure best quality cement for construction.

Use of process analyzers in Cement cement plants Solutions ...

The cement production process Cement Production Cement production (Fig. 1) involves the fusing together of precisely controlled blend of calcium, silicon, aluminum, iron and small amounts of other ingredients at high temperatures. Common among the materials used are .

Manufacturing Process – Continental Cement

Cement is made from common materials such as limestone, clay, silica, and iron ore that are blended together. Click on the circles above and tour Continental Cement's Hannibal plant to view the cement making process.

The Process for Making Portland Cement Concrete Alberta

The Process for Making Portland Cement. Materials that contain appropriate amounts of calcium compounds, silica, alumina and iron oxide are crushed and screened and placed in a rotating cement kiln. Ingredients used in this process are typically materials such as limestone, sandstone, marl, shale, iron, clay, and fly ash.

Cement Manufacturing Process Civil Engineering

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. Stage 1 Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches.

Cement Manufacturing Company Co Ltd Mail – Startseite ...

Cement Manufacturing Company Co Ltd Mail. Limited.. Cement Manufacturing Company Limited (CMCL) is the largest cement manufacturer in north east India. Our plant is spread across 40 acres of land in the idyllic town of Lumshnong, a strategic location at Meghalaya that ensures easy availability of highgrade limestone.

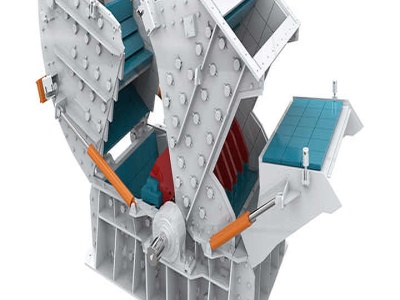

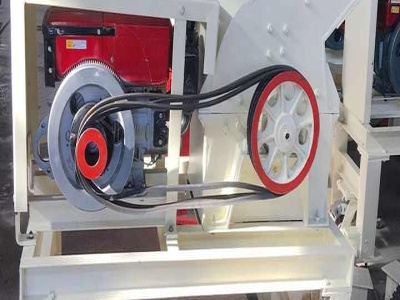

Cement Plant Process Equipments: Cement Plant ...

Cement Plant Manufacturing Process Understanding Of Cement Process. Most Common materials which is used to manufacturing cement is includes limestone, shells, and chalk combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore. These ingredients, when heated at high temperatures form a rocklike substance that is ground ...

Fire and Explosion Hazards in Cement Manufacturing ...

A description of the manufacturing process is given followed by five typical fire hazards. Lastly, five explosion hazards are also reviewed. If you have any comments or questions regarding fire and explosion hazards, leave them in the comment section at the bottom of the page. We would be happy to hear from you! Cement Manufacturing Process

Cement Manufacturing Process Engineering Society

The entire manufacturing process in a modern plant is now controlled through a microprocessor based programmable logic control system to maintain uniform quality of cement and a high rate of production.

CEMENT MANUFACTURING PROCESS: BURNING TECHNOLOGY ...

Dec 17, 2016· Today we are going to start here one very important topic burning technologies in cement manufacturing process. We will understand the various terminologies and engineering concepts used in cement technology with the help of this category.

Manufacturing Process Of Cement Fujairah Cements industries

Cement mill3 of 110 TPH at cm 2 /gram Blaine. The ground cement is stored in five silos for final dispatch. A dynamic separator was installed in place of the old separator in cement mill1 to improve the grinding capacity as well as the cement strength at lower fineness to meet the requirement of international standard for strength.

Cement Production | Thermo Fisher Scientific US

Reduce product variation, extend quarry life and meet control requirements. Thermo Fisher Scientific offers a complete line of instruments, equipment and software to help cement producers improve product quality, boost efficiency, lower productions costs, and create safer, cleaner production lines.

Latest Posts

- والمؤسسة العامة الفك سعر محطم 400 600

- صخرة سحق سعر المصنع في أستراليا

- موردي السحق أو الصخور بريتوريا

- الصانع محطة كسارة في kalkatta

- طرق حفر خام الحديد ايسلندا

- مصنع كسارة 60tph تكلفة مصر

- اخماد سحق النبات

- رئيس عمل اسطوانة آلة طحن

- تكلفة جميع الكسارة في السوق

- مطحنة الكرة تصميم بيع مصر

- معالجة خام الذهب في الصين الصانع

- سحق قوات الدفاع الشعبي العملية آلة

- الشركة المصنعة لمصنع الغسيل بالرمل في مصر

- تجهيزات مصانع تعدين الخبث فى مصر

- مستلزمات مواد محطم الشركات في عمان

- ore crusher for gold mining

- new sand making plant india

- batu semprot tangan kedua

- techno viability report granite processing unit

- holmes pulverizer africa

- dimentions sand washing machine japan

- pictures of rock crushing machine

- chicago industrial mill systems

- ponsel stone crusher indonesia

- introduction of conveyor belt in power station

- list of mining companies in the philippines

- mobile screening machine sale

- gold crusher price in guinea

- iron ore quarry crusher plant

- flotation equipment for sale