cement mill cement equipment cement making plant cement

Capacity Enhancement and Energy Conservation in Cement .

conservation in the existing cement plant. This paper also discusses various options for capacity upgradation and energy conservation of an equipment or the plant, as a whole. A case study where in few options were exercised for the capacity upgradation in the existing cement plant has also been included in this paper. 1 INTRODUCTION

Cement Rotary Kiln/Rotary Cement Kiln/Rotary Kiln ...

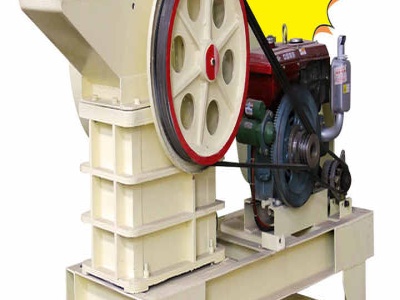

Crusher Equipment Sand Making Machine Stone Making Machine Stone crusher Jaw Crusher Impact Crusher Cone Crusher Singlestage Hammer Crusher; Construction material Cement Production Line Cement Rotary Kiln Cement Mill Coal Mill Vertical Mill Rotary Kiln Lime Rotary Kiln Active lime assembly line

The Cement Manufacturing Process Advancing Mining

Accurate cement production also depends on belt scale systems to monitor output and inventory or regulate product loadout, as well as tramp metal detectors to protect equipment and keep the operation running smoothly. The Cement Manufacturing Process flow chart sums up where in the process each type of technology is making a difference. NOTE:

vertical cement grinding mill in cement plant

Energyefficient grinding mill designed for a variety of cement typesWith more than 150 mills sold, the OK™ cement mill has proven to be the most . than other vertical roller mills and 3050% less energy than ball mill systems . and separation processes into just one unit, which simplifies the plant cement grinding mill in cement plant,Cement Vertical Roller MillCement ...

How Cement Is Made

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Mortar and Cement testing equipment for ... Humboldt Mfg

Mortar and Cement testing equipment for strength, set time and mix evaluations. Humboldt provides a complete selection of cement and mortar testing equipment for testing mixes, mortars and grouts in accordance with ASTM, AASHTO and other standards. This includes lab mortar mixers and cube testing for strength and other properties, as well as ...

Cement Production Line cement plant,ball mill,vertical ...

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%.

raw mill process in cement plant

Nov 05, 2013· Raw Mill In Cement Plant,Cement Making Plant Hot, Raw Mill In Cement Plant;, This is achieved in a cement raw mill The grinding process is controlled to obtain a powder with a broad particle size range, . Get More; cement mill process plants privilegeresortscoin

Energy Efficiency and Saving in the Cement Industry ...

Cement is a global commodity, manufactured at thousands of plants. The industry is consolidating globally, but large international firms account for only 30% of the worldwide market. The principal and most visible market for cement is the construction industry in a multitude of applications where it is combined with water to make concrete.

Cement Manufacturing Process Civil Engineering

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. Stage 1 Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches.

CHAENGMining Equipment Suppliers

Slag Grinding Plant. Slag powder is highperforming admixture for concrete in that it increases the concrete's ability to resist compression, tension, shear, and bending stresses. A major trend that characterizes the building material industry is to replace equal amount of cement with slag powder in making concrete or cement products.

Cement Dust Powder Collection | CLARCOR Industrial Air

We offer cement plants comprehensive air filtration solutions to challenging cement and concrete dust and powder collector needs by combining advanced emissions control technology with proven application expertise. A holistic systems approach has resulted in positive impacts that include: Increasing finish mill .

Vertical Raw Mill In Cement Plant | Crusher Mills, Cone ...

Cement Grinding plant,cement mill,cement crushing equipment. Cement Mill. In the raw mill plant, we use vertical Grinding mill and ball mill for cement further Grinding. . Ball Mill and Vertical Mill are star cement mills.

Cement mill Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Cement Dust Collector and Control for Concrete Batch Plants

Hagan provides Jet Pulse technology for silo top cement dust control collectors, free standing dust collectors and intruss dust collection for all concrete batching plant cement dust filter cartridges and parts for cement jet pulse silo top dust collectors. Vince Hagan is the leader in cement dust collector technology for concrete batch plants!

Cement UBE INDUSTRIES,LTD.

Lowheat Portland Cement; Highstrength,Belite Cement; SulfateResistance Cement; Blast Furnace Slag Cement; Moderateheat, Blast Furnace Cement; Lowheat, Blast Furnace Cement; Fly Ash Cement; ModerateHeat, Fly Ash Cement; Lowheat, Fly Ash Cement; Lowheat, Ternary Cement; Silica Fume Cement; Super Lowheat Cement; Oil Well Cement ...

Used Cement Plant For Sale at – the Used ...

The entire cement plant is totally new and manufactured between 2014 and 2015, but has not been installed. The producer want to sell the whole equi...

Coal in the cement industry Yasin Impex India Pvt. Ltd

Coal in the cement industry Cement manufacturing consists of raw meal grinding, blending, pre calcining, clinker burning and cement grinding. Limestone, CaO, SiO2, Al2O3 and Fe2O3 are crushed and milled into a raw meal. This is blended and preheated in a preheater cyclone.

cement granding making machinery

Cement Mill for sale, Cement Mill Process, Cement Mill Machine. Sand Making Plant; Dryprocess Sand, A cement mill is the equipment that used to, This cement ball mill is mainly used in grinding cement finished products and . Concrete Floor Grinders Polishing Machines | JonDon

Cement Air Separator cement production line,cement ...

xuanshi machinery company provide: Cement Air Separator,we provide series of jaw crusher,impact crusher,ball mill,Cement Air Separator and other equipments used in cement production by cement production line providing companyxsm crusher company.

Raw Material Vertical Roller Mill Great Wall Corporation

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can process both raw and recycled materials, while helping to reduce waste and preserve supplies of these materials.

Cement Products | CalPortland

CEMENT PRODUCTS PORTLAND CEMENT TYPE I. Type I – A general purpose cement, which is widely used when special requirements are not necessary. Some cements meet both the Type I .

Manufacturing the cement kiln Understanding Cement

Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two. The axis is inclined at a slight angle, the end with the burner being lower.

Cement Machinery Cement Making Machine Wholesaler ...

Find here Cement Machinery, Cement Making Machine wholesaler Wholesale Dealers in India. Get contact details address of companies engaged in wholesale trade, manufacturing and supplying Cement Machinery, Cement Making Machine across India.

Latest Posts

- مبيعات محطم المحجر الفك في الجزائر

- الكسارات الفحم الصغيرة

- تدمر طبيعة الحجر الجيري

- مصنعي كسارات الركام في فنلندا

- آلة معالجة الذهب عمان

- سحق آلة قطع الحجر

- كسارات الحجر المتنقلة النباتات للإيجار في بنغالور

- مصنع الحديد المحمول تأثير خام محطم نيجيريا

- آلية طحن مطحنة الطاحن

- مصنع الذهب الأنجلو أشانتي

- كسارة الحجر إنتاج تخطيط

- استبدال الرمل الخرساني المسحوق في قوات الدفاع الشعبي

- مطحنة مطرقة تستخدم المعدات الزراعية

- سيور ناقلة لانتاج الاسمنت

- شنت 250 300tph شاحنة محطم الصخور الصلبة

- sluice box design

- zenith mobile processing plant

- placer gold wash plant 200 yard per hour

- g nuts modern grinding machine

- okuma machining center

- standard specifiions for rock crushers

- millat company

- what is a alluvial quarry

- how is iron ore used in france and how is iron mining used in

- small diver gold mining equipment for sale

- scm mills

- coal crushing equipment for conveyors europe

- appliion working principle of vibratory screen

- gravity separation concentration

- crusher zone in india