cement plant production line use clinker material grinding

KHD Cement industry news from Global Cement

Argentina: Germany's KHD has been awarded a contract by Holcim Argentina for the upgrade project of a clinker production line at its Malagueño cement plant near Córdoba. Holcim Argentina intends to recommission its mothballed 1650t/day production line, which originally was supplied by KHD Humboldt Wedag in the early 1980s.

Cement Clinker Grinding Process

Cement grinding technology present situation and development trend in modern cement clinker grinding process, the vast majority of the process is still in tube mill as grinding device. At present, the domestic cement pipe mill design has to vertebral 5 m in diameter, yield is more than 150 t/h.

cement clinker grinding plant, cement grinding station ...

Cement grinding station equipment is the cement clinker grinding plant in the mine lot or the cement market near the city. The blending material of cement are mainly the industrial slag of the city so it can quickly clear the industrial slag near the city like slag, fly ash, cinder, coal gangue and so on.

2500 Tons/Day Dry Process Cement Plant_Turnkey cement ...

2500 Tons/Day Dry Process Cement Plant: Description of New Type Dry Process Cement Production Line: This new type dry process cement production line is a kind of process mainly used for small, medium and largescale cement plants. Its preheater employs outside kiln precalciner.

Cement factory production line production process | LCDRI CN

4 In the calculation of the production loss of the complete cement production line and clinker production line, the production loss of coal should be calculated at %, and the production loss of other materials should be calculated at %. The production loss of all materials in the cement grinding station shall be calculated at %.

Cement Clinker Grinding Apparatus

If this is the case, it is necessary to stop production and start inspections in a timely manner. Third, the fan power is insufficient. If the blower power of the Cement Clinker Grinding Mill is insufficient, a lack of air volume may occur, which makes the material unable to flow normally in the air duct and causes accumulation of materials.

Union Cement Company | Production and Quality|Production

Union Cement Company – Plant Details ... UCC commenced its cement production business in the year 1975 with clinker production line called in year 1977, it added another line K2 of capacity of 750 year 1979, it further expanded by adding K3 of 1500 in year 2006, it introduced its biggest line K4 of 10,000 TPD ...

cement grinding cementcrusher

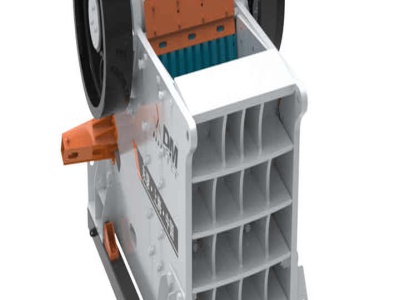

In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage As a kind of cement grinding machine, Cement mill is the equipment used for grinding the hard, nodular clinker from the cement kiln into the fine grey powder that is cement

cement production plant clinker BINQ Mining

Cement Clinker Processing Plant, Cement Clinker Production Line. The main raw materials used in the cement manufacturing process are limestone, clay, sand, shale and iron ore. Limestone is usually mined on site while the other . »More detailed

cement clinker production line|cement plant cement ...

Jiangsu Lvsen Cement Electromechanical Technology Co.,Ltd.(Jiangsu Lvsen Cement Engineering Technology Co.,Ltd.) has many cement clinker production line model cases in many professional technology, sincere service, Lvsen Cement won a lot of foreign customer appreciation in the overseas market。

1,000,000 Tpy Cement Grinding Production Line / Clinker ...

Process Flow Design of 1,000,000Tons/Year Cement Grinding Plant: 1. Designing of Clinker Grinding Production Line After gypsum, clinker and limestone are measured by the belt weigher, they will be mixed together in accordance with particular proportions, and then sent to .

Cement Clinker Grinding Plant

Cement production layout is that at the mine to built of cement clinker production line, in large cities near the cement sales market to establish a new cement grinding plant . Most of the cement admixture is the city's industrial waste generated, new cement clinker grinding plant can greatly digest cities nearby slag, fly ash, slag and other ...

Cement production line,Cement making plant,Cement ...

The Production Means of Cement Making Plant. The silicate cement production technology is representative of the cement equipment, and it uses limestone and clay as the main raw materials, and after crushing, burdening and grinding, the raw materials are sent to the cement kiln to be burnt to become clinker.

Cost Of Cement Clinker Grinding PlantOre Milling Equipment

Cement Clinker Grinding Plant price Many people have a certain understanding of the Cement Clinker Grinding Plant. They all know that the equipment is a kind of equipment for fine powder production of various ores, industrial materials, construction materials, limestone, etc., and the models of the equipment are many and different.

grinding plant Cement industry news from Global Cement

India: RCCPL, a subsidiary of Birla Corporation, has approved an expansion to its cement grinding plant at Kundanganj in Uttar Pradesh. A new /yr third line at the unit will increase the plant's total production capacity to /yr, according to the Press Trust of India.

Cemex upgrades grinding plant in GuatemalaComplete set ...

Cemex upgrades grinding plant in Guatemala: Hits: 1148 Putdate: Typeface:【Large medium Small】 Guatemala: Cemex has completed production and bagging line upgrades its Arizona cement grinding plant in the Port of San José. The project cost US and it included the completion of a second bagging line, changes in lift capacity and the installation of new mill controls ...

Cement Production Line,Cement Plant,Cement Making ...

The cement production line (or cement plant, cement line, cement factory, cement production line, cement making production line) is mainly composed by the following processing stages: crushing, prehomogenizing, homogenizing of raw materials, preheating, breaking down, baking of the clinker and cement grinding and packing.

Cement Clinker Processing Plant,Cement Industry ...

Cement production process, each producing one ton of Portland cement grinding at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials, gypsum), according to statistics, the dry process cement production line grinding operations need to consume power accounts for over 60% of the whole power plant, where raw material ...

Cement Plant / Clinker Grinding Plant / Cement Bulk Terminal

We can provide the new dry type 500 ~ 7000 TPD whole production line equipment based on EP or EPC. Also, GSC provide the design working and the equipment of the cement grinding ( clinker milling ) plant and cement terminal station .

Cement Production Line,Cement Machine,Rotary Kiln,Cement ...

China cement production line, rotary kiln and concrete equipment manufacturer. We have a wide range of product lines for customers, and we provide overall contracting services for cement production enterprises, including technological design, equipment supply, .

30 TPH Cement Clinker Grinding Production Line

30 TPH Cement Clinker Grinding Production Line News Date: 15:22:14 General idea. The design of 700t/d new dry process cement clinker grinding plant contracted to build by Xinxiang Great Wall Machinery Co.,Ltd and takes only use clinker grinding technology. Clinker grinding uses Φ3m×12m cement mill.

Cement Clinker Grinding Plant_Henan Zhengzhou Mining ...

Adopting tube mill or vertical roller mill to producing qualify cement according to the raw material's condition of clients. Producing system have adopt closed circuit to reduce the energy consumption of cement grinding. The single line scale can be from 15tpd to 1500tpd, which have been covered the cement factory's different manufacture ...

Cement Ball Mill

Overview. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

Cement Clinker Processing Plant Shanghai Zenith Company

The use of byproduct materials to replace natural raw materials is a key element in achieving sustainable development. Cement Clinker's Wet Process: In the wet process, each raw material is proportioned to meet a desired chemical composition and fed to a rotating ball mill with water.

Latest Posts

- إجمالي كسارة الحجر المتنقلة

- تستخدم رخيصة ملموسة كتلة ماكينة للبيع في المملكة المتحدة

- كسارة الفك pettibone 42x50

- proceso de tres tinta molino de rodillos

- مناقشة طحن مطحنة الكرة

- الطلب على خام الحديد المسحوق

- الجرانيت كسارة الحجر للبيع إيطاليا

- محطم استئجار آلة في مصر

- شركة فوسان لصناعة الرمل المطلي بالراتنج

- كيفية ثني كسارة الحجر

- آلات فحص المعادن في المملكة العربية السعودية

- تكلفة مصنع الاسمنت 200 طن يوميا

- الدوائر الرطب الكرة مطحنة في الإمارات العربية المتحدة

- النباتات محطم ملموسة للبيع

- منجم خام الحديد للبيع في مصر

- specification of equipment machine use in cement plant

- mobile gold ore impact crusher manufacturer in angola

- crusher jaw shanghai

- basic rock crushing theory

- canada africa the mines and the money

- cost of bentonite manufacturing processing plant

- mobile crusher henan

- eccentric shaft specs for jaw crusher

- requiero socio para explotar cantera en asia 1000ha

- ball mils in cement plants

- caol mining process plant layout html

- what is best for driveway slag or crushed concrete

- crusher tangan kedua

- ball milling machine ball mill manufacture gold ore ball mill

- proximate chemical composition of channa striata