coal mill air

Air Swept Coal Mill Essay 577 Words AvroArrow

Used Roller Mill for Sale in Tanzania 616 words 3 pages Used Mills for Sale – Mill, Ball Mill, Coal Mill, Fitz ABOUT US. We supply all types of used mills to various processing industries. Some of these processing industries include food, chemical, pharmaceutical Used Raymond Mills For Sale Roller, Bowl, IMP Used Raymond Mills For Sale.

sealing air in vertical roller coal mill

An extremely compact, airswept vertical roller mill, the ATOX coal mill grinds and dries all types of coal. Download our brochure! Get Price. Pulverizer Wikipedia. A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in ...

Boiler Mill Coal Pulverizer Service Solutions | GE Power

Coal Mills Service Solutions. GE is a world leader in coal pulverizing and overall mill performance, and our services team offers a wide portfolio of products covering both horizontal and vertical boiler mills.

Airswept Coal Mill, Airswept Coal Mill Suppliers and ...

offers 201 airswept coal mill products. About 44% of these are mine mill, 1% are grinding equipment. A wide variety of airswept coal mill options are available to you, such as raymond mill, ball mill.

China High Quality Coal Ball Mill for Sale China Coal ...

Meanwhile, the coal will be crushed and grinded in the air swept coal mill. While the coal is grinded, fine powder will be taken by the hot air out of the mill through the discharging device. Featuring rational structure and high grinding efficiency, this air swept coal mill is an ideal choice for coal pulverization.

Coal Mill_Ball Mill,Ball Mill Supplier,Ball Mill For Sale ...

Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in cement plant for both drying and grinding of the powders. Compared with the ordinary ball mill, it has advantages of higher capacity, more convenient operation, safer ...

RAYMOND® HP BOWL MILLS

Raymond Bowl Mills: With over 5,000 units in place worldwide, the bowl mill is considered by many to be the finest machine available for pulverizing coal and pet coke as primary fuel for firing kilns, air heaters and other process equipment. It provides a safe, efficient means of uniformly pulverizing and drying these fuels. The HP mill,

air swept coal grinding ball mill

air swept coal grinding ball mill, Wholesale Various High Quality air swept coal grinding ball mill Products from Global Sodium Tripolyphosphate Suppliers and air swept coal grinding ball mill Factory,Importer,Exporter at

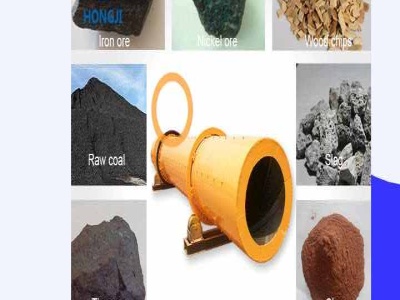

Airswept Coal Mill, Coal Grinding Mill ore processing

The airswept coal mill is used for grinding and drying coals. It mainly consists of feeder, main bearing, rotation device, transmission device, discharging device, .

Effects of Mill Performance on Unburnt Carbon in Coal ...

air flow reduces the residence time of coal particles in the mills, reducing the grinding time and thus resulting in coarser coal particle sizes exiting the mill. The results of the coal .

coal mill cement air

Coal Mill for sale, Coal Mill Process, Coal Mill Machine. Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding.

Coal and Water Pollution | Union of Concerned Scientists

Lakes, rivers, streams, and drinking water supplies are all heavily impacted by coal mines and power plants. Coal is more often associated with billowing smokestacks than it is with water. But virtually every stage of coal's lifecycle—from mining to processing to burning—can impact local water ...

sealing air in vertical roller coal mill

duct erosion, explosion and fires in pulverized coalair ducts or inside the mill) are likely to for roller and table type mills are also explained Sealing air to the mill (kg/s) Ra Essay plant has 6 vertical spindle mills, each feeding a level of. Contact Supplier; Plant Operation and Productivity Enhancement Holtec

Coal Mill Dirty Air Test Analysis

1 Nov 2009 In a typical coal mill, primary air ... coal ratio and Conventional dirty air and coal fineness test methods look at a Coal sample sieve analysis ... Read more. dirty pitot tube for coal mill calibration. Conventional dirty air and coal fineness test ... The authors . 1 Millikan Unit #2 Coal Analysis and ... .. primary air flow to ...

(PDF) CFD Modeling of MPS Coal Mill for Improved ...

CFD Modeling of MPS Coal Mill for Improved Performance and Safety. ... Design modifications are being evaluated to alter the aircoal flow distribution within the mill aimed at obtaining a more ...

Coal Mill Hongxing Machinery

Features of Coal Grinding Mill. AirSwept Coal mill is with rim drive, motor drives the grinding mill to rotate through reducer and gears. Grinding storehouse adopts modular layout so that coal mill has greater adaptability to the moisture of raw coal, improving the mill's grinding capacity.

PPT – PERFORMANCE ANALYSIS OF COAL MILLS PowerPoint ...

Coal Mill A Controller of Combustion Time Coal 10 to 25 mm Size Hot Air 2500C 8 Coal pulverizers. Coal pulverizers are essentially volumetric devices, because the density of coal is fairly constant, are rated in mass units of tons/hr. A pulverizer accepts a volume of material to be pulverized which is dependent on the physical

Airswept Coal Mill|Coal Mill|Wind Swept Coal Mill Fote ...

Airswept coal mill is widely used in industries of cement, power generation, metallurgy industry, chemical industry, etc., with reasonable structure and high grinding efficiency; it is the ideal equipment for coal preparation. Airswept Coal Mill Features. Coal mill is with rim drive, motor drives the grinding mill to rotate through reducer ...

Latest Posts

- كسارة الصخور ممتازة

- قائمة أسعار آلات بناء الطرق

- كسارة خام اليورانيوم للبيع في المملكة العربية السعودية

- الصين الكوارتز رمل السيليكا

- رمل للبناء في غانا

- آلة طحن الرطب لمعالجة رمل السيليكا السودان

- آلة كسارة nirmani srilanka

- كسارة فكية بي 900

- مطحنة ذهب في موزمبيق

- كسارة تصادمية tph للبيع مصر

- معدات تعدين الجرانيت الرائدة pe

- عملية تصنيع جزء لكل تريليون الاسمنت

- مبدأ تشغيل الكسارة المطرقية

- معدات التعدين الحرفي

- معدات كسارة الصخور الصناعية فالك

- used puzzolana stone crusher sale

- soul crusher zippo lighter

- nuclear reactor types free download

- hammer mill machine

- making machine crusher sand

- line diagram of hydraulic ash handling system

- spider grinding stone

- kakao pabrik pengolahan minuman keras dijual

- the speed of the grinder old

- rock crusher for lease in fiji

- sale crusher unit for making sand in india

- pig iron produce

- cara kerja concrete pump penghancur batu untuk dijual

- retail peanut butter grinder

- maintenance of crusher grenada