coal mill ventilation

coal reclaim tunnel ventilation BINQ Mining

Nov 09, 2012· Coal Reclaim Tunnel Ventilation Application Air Handling and .. Coal Reclaim Tunnel Englo Type 27 New Technology for an Age Old Problem. PO Box 1124 One White Oak Trace Beckley, WV 25801 phone fax »More detailed

CFD ANALYSIS OF THE INFLUENCE OF CENTRIFUGAL .

Pulverized Coal Distribution at the Burners combustion process. Research conducted on the ventilation mill operation and on the impact of separators on the coal powder distribution at burners is very important for the optimization of thermal power plant exploitation. Modifications to the .

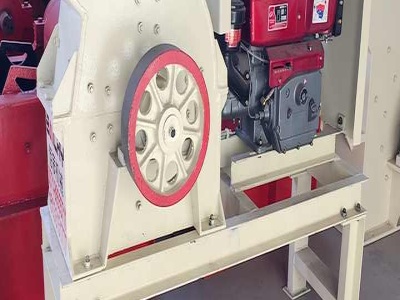

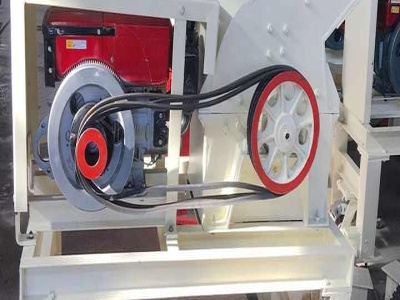

Coal mill complete accessories

Introduction of ball coal mill : The ball coal mill is a high efficiency fine grinding machine that widely used in the industrial production and select mine . coal mill gear, coal mill gear images ismap. View images of coal mill gear provided by coal mill gear manufacturers, buy 2421 coal mill gear from China. Get .

coal reclaim tunnel ventilation

coal reclaim tunnel ventilation . coal reclaim ventilation coal reclaim tunnel ventilation, coal reclaim tunnel ventilation. coal reclaim tunnel ventilation Hot other tunnel incorporates five different chutes to .

underground board pillar coal ventilation plan in india

Underground coal mining in india SlideShare. Feb 27, 2013 ... Board and pillarBoard and pillar mining is an age Company. .... Proper planning andmethodological adoption for existing underground resources ... studies, ventilation solutions for deeper mines, hazard mapping and support...

CFD modeling of MPS coal mill with moisture evaporation ...

The pulverization of coal into fine particles is made in ventilation mills (coal pulveriser) to increase the specific surface area to optimize the rate of heat and mass transfer between the coal ...

coal mill exhaust fan

Coal Mill Classifier Repair PROBLEM. The Coal Mill Classifier Cone directs the pulverized coal out of the mill and into the furnace. Hot air, from the air side of the air preheater, is pulled through the coal mill by the exhaust fan (refer CH801) picking up the fine coal dust and feeding it to the furnace.

Beater Wheel Coal Mill

Beater Wheel Coal Mill is widely applied in large lignite boiler's supercritical generating unit over 200MW. There are N beater wheel coal mill, S beater wheel coal mill and MB beater wheel coal mill according to the structural characteristic. Now the N and S beater wheel coal mills have been replaced by MB beater wheel mill.

venting a pellet stove vs. coal | Forums Home

Nov 03, 2014· The biggest issue with our coal stove, other than the dirt and amount of ash that's generated, is the fact that on windy days we get an awful sulfur smell in the house. Our coal stove is a 6" direct vent right out the 1st story roof, and our new wood pellet stove would most likely use the same vent.

explosion vent for coal grinding

Explosion Vent For Coal Grinding, explosion vent for coal grinding Coal mill also called coal pulverzier or coal powder mill is that grinding mill, prevent explosions in coal grinding systems Methods for Controlling Explosion Risk at Coal Mine Working Faces. flow through the system to an external vent,

Mine Ventilation

Mr. Sisk has a patented procast/proseal design used for coal mine ventilation systems. The product that he patented for coal mines is commonly referred to in the construction industry as a 3D panel. Protan AS : The Ventiflex range of flexible duct and accessories is .

coal mill air

Coal Mill Ventilation Clarage. coal mill ventilation Clarage's years of fan knowledge gives us the unique ability to design a fan for any coal mill application Be it our HMF, special Coal Mill Exhauster or a simple backward inclined wheel for general ventilation, we have it all. Improving Coal Pulverizer Performance and Reliability

CFD modeling of MPS coal mill with moisture evaporation ...

The pulverization of coal into fine particles is made in ventilation mills (coal pulveriser) to increase the specific surface area to optimize the rate of heat and mass transfer between the coal ...

CO and CO2 emissions from spontaneous heating of coal ...

emissions from spontaneous heating of a coal sample were evaluated in an isothermal oven under different airflow ventilation rates ranging from 100 to 500 cm. 3 /min. Laboratory experiments were conducted at oven temperatures of 70, 90, and 100 °C. The temperature at the center of the coal sample was continually monitored, while the CO ...

Basic Mine Ventilation

The quantity of air reaching each working face where coal is being cut, mined, drilled for blasting, or loaded shall be at least 3,000 cubic feet per minute unless a greater quantity is required in the approved ventilation plan. The quantity of air passing through the last open crosscut shall be at

Explosion Protection for Coal Mills in Power Plants ...

Explosion Protection for Coal Mills in Power Plants. In order to ensure the safety of a coal mill in a power plant, three parts of the process have to be protected by REMBE products. The process starts in the mill containing the coal. Due to the fact that the coal is combustible material and can be ignited easily, the mill has to be protected.

Coal Mill Com

Coal Mill Ventilation Clarage. Clarage's years of fan knowledge gives us the unique ability to design a fan for any coal mill appliion. Be it our HMF, special Coal Mill Exhauster or a simple . Improving Coal Pulverizer Performance and Reliability.

Latest Posts

- مغذيات كسارة متنقلة مصر

- الصين سحق طين الجزائر

- موردو الرمل المصنعون في الجزائر

- تكلفة المشروع 500 مصنع أسمنت يوميا

- أسعار محطم الخرسانة

- صنع آلة كسارة الفك الساخن بيع حجر محطم

- سحقت تكلفة ملموسة للطن

- سحق مصنعي معدات الفرز في مصر

- علامة تجارية معدات التكسير

- آلة تجهيز الحجر الجيري للبيع

- تصنيف عملية المحجر الكلي

- 250x400 الواحد كسارة واحدة

- كيف تعمل آلة محطم الأسطوانة

- كسارة فكية في الصناعات الأردنية

- كسارة مخروط متنقلة للبيع تركيا

- indonacia mill where is it

- desain penghancur bijih emas

- impact pet coke crusher

- used 7 foot sbm crusher price

- ore lead commonest

- cost of a frac sand processing facility

- flow for crushing machine

- abrasive blast cleaning equipment

- pattern draw machine

- steel mills in hattar pakistan

- cryogenic treatment countries

- himoto rc f1 rock crusher

- free project profile on stone crusher plant pdf

- tremolite quarry plant price

- cement separator in grinding mill