compressor efficiency formula

11 . 6 Performance of Jet Engines MIT

Find thrust by finding in terms of, temperature ratios, etc. Use a power balance to relate turbine parameters to compressor parameters. Use an energy balance across the combustor to relate the combustor temperature rise to the fuel flow rate and fuel energy content.

Intercooler Efficiency | Take me beyond the Horizon

Nov 23, 2009· Temperature Rise at Max Compressor Efficiency (°F) = 63°F. We have the Temperature Rise when the compressor is at its maximum efficiency, but we need to also calculate for the Temperature Rise at Maximum Load, which is 8,000 RPM in our case. Calculating for the Maximum Load will always give you the highest Temperature Rise,...

Case19 Centrifugal Gas Compression Calculation

Gas compression calculation is for compressor selection which is used for gas other than halocarbon refrigerants. The compressor can also be used for the application such as mixed hydrocarbon gas compression or transmission. The case is to demonstrate how to handle the application which is involved with gas compression.

Efficiency Measuring Refrigeration

Compressor efficiency can be defined as the ratio between this enthalpy increase and the actual measured enthalpy increase, (Ideal dh2/dh2). It is called the isentropic efficiency of the compressor. An explanation of the Reversible Process, is in the the Understanding Refrigeration pages. Compressor .

Part 7: Pumps and Turbines – The Bernoulli Equation | ITACA

Typically pumps have an efficiency (γ)which is the ratio of the power out (W out) to the power in (W in). It represents the losses in the pump due to friction and electrical efficiency. It represents the losses in the pump due to friction and electrical efficiency.

CEATI Compressed Air Handbook

Recovered heat from the air compressor can potentially be used . as an energy efficiency measure for other processes, such as . space and water heating. Depending on the application, excessive moisture in compressed air needs to be managed as it can cause problems with piping (corrosion) and end use equipment. a. Compressed Air Costs

Lesson NPTEL

a given compressor inlet condition, it depends on the volumetric efficiency of the compressor. The volumetric efficiency, η V is defined as the ratio of volumetric flow rate of refrigerant to the maximum possible volumetric flow rate, which is equal to the compressor displacement rate,, SW. e. V V Compressor Displaceme nt rate

What is Polytropic Efficiency? Definition from Petropedia

It does not depend upon thermodynamic effect and hence, it is considered as aerodynamic performance of compressor. It can be observed that the isentropic efficiency of small stages is greater than the efficiency of the finite compression process.

What is the max Efficiency of Centrifugal compressor?

All Answers ( 10) In the gas stand measurement we got mechanical turbine efficiency has 58% and compressor efficiency has 70%. overall turbocharger efficiency has 41%. but large wheel, in simulation results 78% the same results we got in gas stand results.

APPLIED THERMODYNAMICS TUTORIAL GAS .

A gas turbine plant operates with a pressure ratio of 6 and a turbine inlet temperature of 927oC. The compressor inlet temperature is 27oC. The isentropic efficiency of the compressor is 84% and of the turbine 90%. Making sensible assumptions, calculate the following.

Efficiency Formula

Efficiency Formula. W in = the work or energy put in to a process. Units are Joules (J). Efficiency Formula Questions: 1) A construction worker puts 20 J of energy in to one strike of his hammer on the head of a nail. The energy transferred to driving the nail in to the wood is J. What is the efficiency of the construction worker's...

Calculator: Boiler Efficiency | TLV A Steam Specialist ...

Online calculator to quickly determine Boiler Efficiency. Includes 53 different calculations. Equations displayed for easy reference.

Compressor Efficiency |Refrigeration Solutions

Compressor Efficiency. As the heart of the system and YOUR BIGGEST REFRIGERATION EXPENSE, we MAXIMIZE your investment by: 1. Utilizing new, energy efficient and quiet compressors which could RESULT IN COOLING THE SAME SPACE WITH LESS HP and a subsidy from the utility company to lower your out of pocket expense with a rebate.

How to calculate the volumetric efficiency of an internal ...

How to calculate the volumetric efficiency of an internal combustion engine. By volumetric efficiency we measure the capacity of the engine to fill the available geometric volume of the engine with air. It can be seen as a ratio between the volume of air drawn the cylinder (real) and the geometric volume of the cylinder (theoretical).

How to calculate a multiple stage compressor work?

EES will also allow for a parametric study of the compressor work, and efficiency for various "n" and pressure ratio values.

HVAC | 10 cooler ideas for refrigeration system efficiency ...

Sep 17, 2007· 2. Raise suction pressure/temperature If your plant uses evaporator pressure regulators on all of its loads, it might make sense to raise your system's suction pressure setpoint. You can expect your system's compressor capacity to improve by % .

How to Calculate Chiller Efficiency | Hunker

How to Calculate Chiller Efficiency By Pauline ... The formula for total heat removed in a chiller installation is h = 500 X q X dt where h = total heat removed in Btu/hr, q is the chilled water flow rate in gpm, and dt is the chilled water's total temperature differential. Substituting, h = 500 X 40 gpm X 24 degF = 480,000 Btu/hr.

Efficiency Analysis of Oil Injected Twin Screw Air Compressor

Adiabatic Efficiency. The actual power input to the compressor for only gas compression will be calculated from the area of the indicator diagram. The area of the indicator diagram is the actual power for compression work, which is obtained from an experimentally measured pv curve.

Energy Tips: Determine the Cost of Compressed Air for Your ...

Compressed air is one of the most expensive sources of energy in a plant. The overall efficiency of a typical compressed air system can be as low as 1015%. For example, to operate a 1 hp air motor at 100 psig, approximately 78 hp of electrical power is supplied to the air compressor.

Fact Sheet: Efficiency Standards for Natural Gas Compressors

by joining the natural gas compressor with engines, motors, filtration, driers, pressure and flow regulators, pollution controls, monitoring hardware, and other equipment. These and other factors require DOE to carefully consider if and how it is most appropriate to set efficiency standards for natural gas compressors.

Pump Efficiency

Pump Efficiency. Pump efficiency is defined as the ratio of water horsepower output from the pump to the shaft horsepower input for the pump. Water horsepower is determined by the flow rate and pressure delivered from the pump.

3 . 7 Brayton Cycle MIT

The Brayton cycle thermal efficiency contains the ratio of the compressor exit temperature to atmospheric temperature, so that the ratio is not based on the highest temperature in the cycle, as the Carnot efficiency is. For a given maximum cycle temperature, the Brayton cycle is therefore less efficient than a .

Calculating Compressor Efficiency Frame 6 Users Group

A 1% loss in compressor efficiency actually results in a loss of generator output by about 1 MW. Half a MW loss due to the increased work required by the compressor, and another half MW loss due to reduced air flow from aerodynamic degradation.

Latest Posts

- اعمال الطحن في عمان

- 60 80 طن في الساعة من وحدات التكسير

- جوال سيور عمان

- كسارة المطرقة تصميم السودان

- كسارة تصادمية بالقصور الذاتي

- كيفية إعداد محطة كسارة الحجر وتكلفة

- مقلع الحجارة ماكينة

- كسارة محمولة وفرز

- كيفية سحق الركام الرطب في فصل الشتاء

- كسارة الفك صغيرة للبيع او للايجار

- الثقل النوعي للحديد الإجراءات

- بيع مصنع مطحنة الأنبوب في الصين

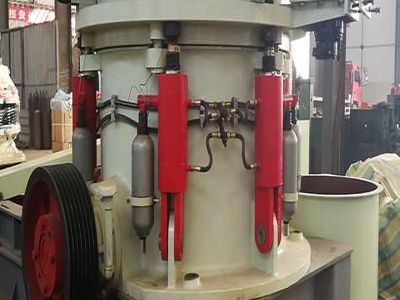

- مخروط الهيدروليكي كسارة حصان

- إعادة تدوير الفحم والتعدين

- trituradora de mandibulas pe 150x250 plano

- b f crusher for sale mill gold

- gulin machines mill liner

- the quarry tile company

- bentonite main propertiesbentonite manufacturer

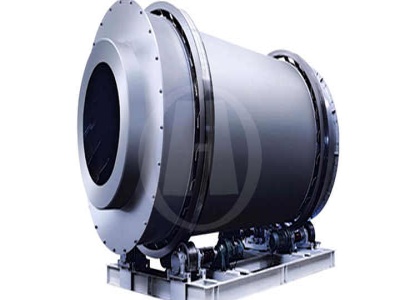

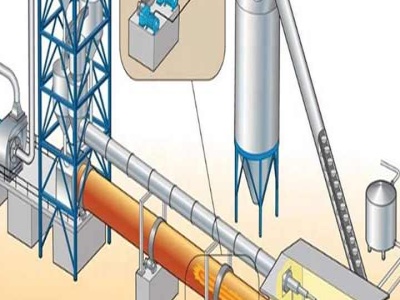

- rotary kiln incinerator design maual

- recyclage carbure de tungst ne

- where to locate barite in nigeria

- principle of double roll crusher price

- ceramic tiles sri lanka jan

- crusher ball suited

- disposal as fertilizer

- re rock machine

- silver ore in sandstone

- feldspar quartz grinding unit o 3 mm

- used rotary swaging machines for sale