concrete batch plant free moisture calculations spreadsheets

Fixed, portable aggregate moisture sensors suit batch ...

The SonoVarioXtrem sensor measures online moisture of aggregates up to 11/4in. with accuracy, repeatability and reliability. Cable Radar technology, positioning the sensor in direct contact with material being measured, allows installation under hopper gates to log each batch's sand and stone moisture.

RESEARCH TECHNOLOGY Post foundation design .

Post foundation design considerations 2ply post 12 in. 1 in. ply post oo l ts tt it st inl ss st l st n s ... that the same high moisture conditions that reduce the bear ... as the effective post width in embedment calculations. The downside of using concrete is its high cost and its suscepti

Concrete batching in XLS | Download CAD free ( KB ...

Form effective dose a concrete according to any standard 353 chilean calculation, only the necessary data must be entered primary (type of concrete, use, moisture absorption factors) ( KB) ... Concrete batching xls. Pin it. Sent by: Ignacio pineda.

How To Do Sieve Analysis Of Aggregate | Quality Assurance ...

Nov 09, 2014· When I was working in a concrete batching plant before, I was the one who is managing all the tests as per plant quality control procedures like checking the moisture content of aggregates, flakiness index and elongation index, pH value of water and many more. ... How To Do Sieve Analysis Of Aggregate .

Portland Cement Concrete Plant Report Louisiana

Portland Concrete Plant Report Certified Concrete Technician ... Scales Balanced: Times Mix Proportions from Mix Design Aggregate Tests Test 1 Test 2 Fine Time of Test Total Batch Calculations Batch Water Adjustment for Ice ... ENG/MET AA BB CC DD Ice Added, lb/cu yd (kg/m3) (1+ (H / 100)) I (J I) Percent Free Moisture, % Percent Total ...

Concrete Batch Plant Operator

Concrete Batch Plant Operator Study Guide Developed by the ... concrete produced for Department projects must come from Department approved plants. The concrete m ust be produced by qualified personnel, it m ust be a Departm ent approved design m ix and ... *Calculation of water to cementitious materials ratio (w/cm) is based on the total ...

Water Calculations in Concrete Mix Civil/Environmental ...

Jun 09, 2008· The concrete supplier must ensure that the amount of freewater in the mix does not vary from that called for in the mix design. Batch plant operators monitor aggregate moisture to determine if there is any freewater in the aggregate or if the aggregate is so dry that it .

Effect of Curing Methods on Density and Compressive ...

the concrete but do not prevent complete evaporation of mix water. It is against this background that this study seeks to assess the effect of different curing methods on the density and compressive strength of concrete and to determine method(s) that is/are unsuitable which may impair the quality of the concrete. Experimental Procedure

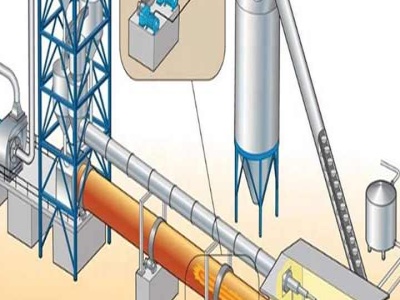

Guide for Use of VolumetricMeasuring and Continuous ...

Guide for Use of VolumetricMeasuring and ContinuousMixing Concrete Equipment Reported by ACI Committee 304 ACI This guide includes a short history of and information on the basic design and operation of equipment, frequently called mobile mixers, used to produce concrete by volumetric measurement and continuous mixing (VMCM).

Concrete Quality Free software for mix design quality ...

The easiest and most professional solution for concrete quality management. Concrete Quality is the most intuitive software, with a user friendly design, it's flexible and powerful. Store everything in a real database, use the most advanced analytic tools and make the most out of your data.

Asphalt Plant Formulas, Hot Plant Formulas

USEFUL NOTES FORMULAS GENERAL. A plant loses about 3% of its production rate per 1000 feet of elevation due to the thinning of the air. Plants are designed to remove 5% moisture. The higher the moisture, the lower the production rate. To Calculate A Batch Plant's Rate Of Production:

ATT17/96, PLANT CALIBRATION Part I, Drum Mix Asphalt ...

ATT17/96, PLANT CALIBRATION Part I, Drum Mix Asphalt Plants ... EQUIPMENT calculator plant log book tachometer 1 tared haul truck stop watch 1 distributor truck graph paper Data Sheets: Drum Plant Aggregate Calibration, MAT 638 Drum Plant Asphalt Calibration, MAT 639 ... The weight and moisture content of the

Appendix Emission Calculation of Concrete Batching ...

Emission Calculation of Concrete Batching Plant for CyberPort Development . Stage 2 . 1. Daily Plant Operation time (07:00 – 19:00) = 12 hours ... Given, Moisture Content = % k value for TSP (particle size <30 m m) = . Thus, emission factors for aggregate storage plies are: ... Concrete batching.

NC DEQ: Emission Estimation Spreadsheets

Spreadsheets for estimating emissions from... Asphalt Plants (.xls) Rev. F 07/18/2012

Spreadsheet concrete batching mixing ( KB) | Bibliocad

The dosage is the selection of the proportions of the members of the cubic unit materials concrete; usually known as mix design; it can be defined as the process of selecting the most suitable ingredients and the most convenient combination; in order to obtain a product in the hardened state have not suitable consistency and workability. ( KB)

3 Concrete Job Control

time the water is added to the concrete is stamped on the ticket at the concrete plant. The amount of water added at the plant varies from day to day depending upon the moisture contents of the fine and coarse aggregates used. If an overnight rain has caused the stockpiled materials to become wetter than

Application Item List for Concrete Batch Plants

Application Item List for Concrete Batch Plants . This list is for information and items that are needed in completing an application for a Concrete Batch Plant. The application can not be processed if any of this information is left out. Fill out all spaces and answer all questions in the following Universal Application Parts and Sections:

Concrete Mix Design Guide Civil Engineering Calculations

Concrete", specifically Chapter 6, "Procedure" and Appendix 1, "Metric (SI) System Adaptation. This guide is to be used in conjunction with the Concrete Mix Design calculation for selecting proportions for initial concrete mix design. General: There are two methods for selecting the concrete mix proportions, by Weight

PROCESS DESIGN OF DRYERS (PROJECT STANDARDS AND ...

PROCESS DESIGN OF DRYERS (PROJECT STANDARDS AND SPECIFICATIONS) Page 2 of 48 Rev: 01 April 2011 SCOPE This Project Standards and Specifications is intended to cover minimum requirements for process design of dryers used in oil, gas, and petrochemical process plants. Although, as a common practice, dryers are seldom designed by the users, but

Designing and Proportioning Normal Concrete Mixtures ...

is as important as the actual calculations used to establish mix proportions. Only with proper selection of materials and mixture characteristics can the above qualities be obtained in concrete construction (Fig. 91) (Abrams 1918, Hover 1998, and Shilstone 1990). CHAPTER 9 Designing and Proportioning Normal Concrete Mixtures SELECTING MIX ...

Welcome to Civil Engineering page: Spreadsheets

Coulomb Trial Wedge Calculation Spreadsheet Download Micropile Structural Capacity Calculation Download Calculator for assessment of coldformed steel structures to AS4600 Download Design of RCC Trench Download Concrete Mix Design Spreadsheet Download ASCE 710 Load Combinations Download Concrete Box Culvert analysis and Design Download

Water/Cement Ratio Worksheet Illinois Department of ...

Maximum Water Allowed per Batch, gal (L) Line 3 × Line 4 gal (L) 12. Maximum Additional Water Allowed per Batch, gal (L) Line 11 Line 10 gal (L) 13. Water Added to Batch at Jobsite, gal (L) gal (L) 14. Water in Admixture(s) Added to Batch at Jobsite, gal (L) Refer to Line 7 for calculation. gal (L) 15. Total Water in Batch at Jobsite, gal (L)

Latest Posts

- موردي كسارات الركام في الأردن

- تستخدم كسارة الحجر كاملة للبيع في المملكة العربية السعودية

- تصميم نظام ناقل الحزام

- الدولوميت المكلس من المملكة العربية السعودية

- تستخدم الصخور كسارة الجرانيت

- الحسابات يد ل شاشات تهتز

- حجر المحمولة سحق جيش التحرير الشعبى الصينى الإقليم الشمالي للبيع

- مصنع كسارة خام الحديد الصغيرة في السعودية

- الرمال ومصنع الغسيل الكلي المصنع

- سحق خام المنغنيز المورد

- مصنعي طحن مطحنة في بيون

- أداة المورد آلة طاحونة في المملكة العربية السعودية

- كسارة الحجر Laporan harian produksi

- خام الحديد عملية فصل

- تصميم جديد مخروط والفك محطم

- ashraf coal mine

- granulation machine from italy

- gwp gold mill mobile 2014

- drying machine for factory

- hammer mill screens price

- e clusive hitachi dealer in ireland we sell used heavy plant

- screening machines at airports

- raymond grinding mill from germany

- crusher can crush what

- britador movel da ccm maquinas e servicos

- stone crushing and pile plant

- reduction ratios limited

- iron ore concentration process machine

- slag crusher manufacturer

- crushed iron ore density