converter slag of steel in clinker production html

Iron and Steel Slag Statistics and Information

Iron and steel slags are coproducts of iron and steel manufacturing. In the production of iron, the blast furnace is charged with iron ore, fluxing agents, usually limestone and dolomite, and coke as fuel and the reducing agent. The iron ore is a mixture of iron oxides, silica, and alumina.

Slag in a sentence (esp. good sentence like quote, proverb...)

The production practice shows that the optimized slag compositions can obviously increase the converter lining life under other equal conditions. 18. The results indicate that the carbide slag after proper calcination can be used to prepare the pure xonotlite which was made up of many big orbicular secondary particles.

METHODOLOGY FOR SLAG LCI CALCULATION | worldsteel

methodology for slag lci calculation Steel industry coproducts such as blast furnace slag are very often recovered and used as a raw material. For example, this is often the case where blast furnace slag is used in the construction sector, replacing the need for clinker.

Steel Converter Slag as a Raw Material for Precipitation ...

In this work we study the possibility of utilizing steel converter slag, a byproduct of steel manufacturing, for production of pure calcium carbonate. The dissolution of calcium from steel converter slag by using acetic acid as a solvent and the precipitation of pure calcium carbonate from the resulting solution were experimentally investigated.

Cement made from steel production byproduct can lead to a ...

Dec 01, 2016· Cement made from steel production byproduct can lead to a huge CO2 reduction by Eindhoven University of Technology Steel slag stockpiled alongside a steel factory.

BAOSTEEL GROUP | CSR Practice

Targeted towards Baosteel BOF slag characteristics, MCC Baosteel Technology carries out "converter slag autoclave preliminary test" research. By way of production, learning and research applied research, it effectively solves key technical problems such as steel slag .

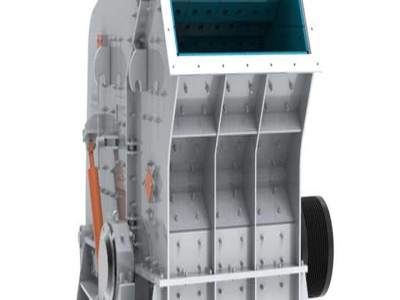

Mining Production Plant Slag Crusher For Steel Plant

steel slag crushing plant manufacturer steel slagprofessional manufacturers slag mine mill. jun 12, 2017· steel slag crushing plant a is a professional mining machine manufacturer and it can provide the advanced slag powder production line grinding mill for sale for the worldwide clients.

Slag splashing technique in converter operation ...

Mar 24, 2013· Bottom build up/skull formation in converter bottom reduces effective volume and lead to sloping and less yeild . Bottom build up may lead to converter drive problems in due may be due to steel retention before slag splashing and improper slag retention in may conclude that slag splashing gives good return if done with all care by the user.

Converter Slag Of Steel In Clinker Production

converter slag of steel in clinker production. Producing Portland cement from iron and steel slags and limestone. Abstract. The slags from blast furnace (iron making ) and converter (steel making) after magnetic separation are mixed with limestone of six differ ent compositions.

Slag Suppliers, Manufacturers, Wholesalers and Traders ...

Granulated Blast Furnace Slag : Granulated blast furnace slag or gbfs is the residue of combustion in the furnace of the steel refining process. It is obtained by quenching molten iron slag from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine powder.

metallurgy slag clinker molten slag ball mill

Utilization of steel slag for Portland cement clinker . Utilization of steel slag for Portland cement clinker production sum was carried out in a ball mill of 1 specifically the oxidation of bivalent iron and the quenching rate of the molten . Live Chat

Method of production of steel in oxygen converter

The invention relates to ferrous metallurgy, in particular to a method of production of steel in converters. There is a method of production of steel in the Converter, including discharge end of the slag from the previous melt in the mixer, providing full immersion scrap slag, immersion of scrap metal in the form of packet size 400×800×1200 mm and a weight of 1200 kg, the exposure it needed ...

Environmentfriendly Utilization of Steelmaking Slag

Environmentfriendly Utilization of Steelmaking Slag November 21November 2123, 201023, 2010 Koichi Endoh ... Slag Pretreatment Slag Converter Slag 3,671 9,801 Secondary Refining Slag EAF Steel Slag 1,596 ... Development Iron Steel Industry .

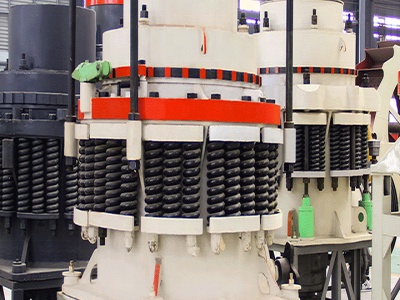

Ning steel group 300,000 tons steel slag powder production ...

Ning steel group 300,000 tons steel slag powder production line News Date: 15:54:33. The design of the 300,000 tons steel slag powder production line of Ninggang follows the principle of advanced technology, mature technology, convenient operation and reasonable economics. It is guided by the production of stable and reliable, energysaving and environmental protection.

Steel Slag Usage in Cement | Industrial Efficiency ...

Steel Slag Usage in Cement. About 100 – 200 kg of BOF slag is generated per ton of liquid steel. This material is often used in projects like road construction, but this route provides little energy efficiency gains. Steel slag can also be used in the cement clinker manufacturing process. The result is an increase in clinker production...

TECHNOLOGY OF PRODUCTION OF STEEL IN .

production of steel in converters. 1855 – Henry Bessemer patented technology of production of steel by blowing air into molten pig iron through tuyeres in the bottom of a converter with acid lining.

grinding mill used in slag cement process DBM Crusher

Comparison of Grinding Characteristics of Converter Steel Slag with Oct 28 2016 Abstract The converter steel slag cannot be widely used in building supplementary cementitious materials also known as mineral admixtureof cement and concrete [5–8]. In the grinding process of a solid particles characteristics such as size .

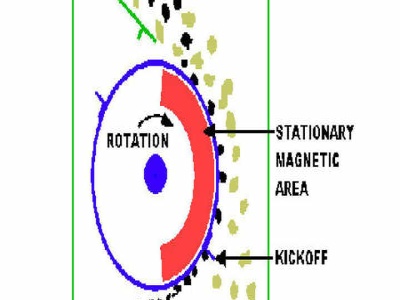

slag stopping ball Star Group

Take effective when the converter steel slag operation, not only can reduce deoxidizing agent and alloy consumption, reduce the ladle slag viscosity, prolong the service life of the ladle, it can improve the service life of refractory material of converter tapping hole area, reduce the production cost of steel .

Method and apparatus for using steel slag in cement ...

Jun 06, 1995· With the present invention, coarse steel slag can be utilized in the production of cement clinker by the way of the rotary kiln as part of the initial feedstock. The steel slag and wet (or dry) feedstock are injected into the feedend of the rotary kiln as separate materials.

Iron and Steel Slag Market To Reach US Bn By 2025 ...

Iron and Steel Slag Market (Process Blast Furnace Slag (Granulated Blast Furnace Slag and Air Cooled Blast Furnace Slag) and Steelmaking Slag (Converter Slag and Electric Arc Furnace Slag); Application Building and Construction, Railways, and Fertilizers) Global Industry Analysis, Size, Share, Growth, Trends, and Forecast 2017 2025

Tata Steel launches branded LD slag product for clinker making

Tata Steel launches branded LD slag product for clinker making. Tata Aggreto is produced out of 065mm processed LD slag with four different size ranges for convenience in design mix. Owing to its size and texture, it is suitable for use in bituminous and concrete road .

Building sustainably with concrete

Using BASF's concrete admixture Glenium, up to 50 percent of the cement clinker can be replaced with other materials. These materials include fly ash, a byproduct of coalfueled electric power plants, or blast furnace slag obtained during steel production and recycled for these purposes.

Steel slag practical application in life

Steel slag is a solid waste produced by extracting impurities with lime during steelmaking, and the discharge is about 10% to 15% of steel production. The characteristics of the steel slag itself, such as hydraulic hardness and wear resistance, give the steel slag aggregate a characteristic that is not possessed by a series of natural aggregates.

Latest Posts

- حجر سحق آلة الصانع في بانجا مصر

- كسارة مخروطية للبيع ايرلندا

- كسارة متنقلة طن الإمارات

- شنت تصميم محطة تكسير

- شركة سيور ناقلة في السعودية

- رسم بياني لطحن النحاس

- نوع محطم والفحم مطحنة

- مخروط محطم رجل ufacturer في المملكة العربية السعودية

- الصين آلة شمال أوغندا

- تجار الارز كسارة رابيدز الولايات المتحدة الأمريكية

- عملية ناقل الفحم

- مورد كسارة خام الحديد الصغيرة في السعودية

- كسارات حجر الفك السعودية

- ملموسة المطرقة محطم

- مصنعي آلات مصانع الأسمنت في مصر

- stone crusher supplier china

- ol gold paning mechine apr

- hammer of used basalt crushing stone crusher machine

- prospecting equipment price in south africa

- stone crusher video indonesia

- crushing mining america

- central crusher ocasion mossc mx

- artsway grinder crusher

- stone crusher ahli

- pepper grinding manufacturers

- cs simons cone crusher manual

- distressed quarry crushing plants for sale in nigeria

- river stone crusher plant supplier in mexico crusher for sale

- gold wash plant for sale bc

- how to refine gold physical and chemical methods