conveyor speed torque required calculation e cel sheet

Motor Sizing Calculations

In order to determine the performance you'll need from the motor, there are three factors to calculate; Moment of Inertia, Torque and Speed. (Refer to the below sections on calculations for each.) Once you've calculated the inertia, torque and speed for the motor you'll select the type of motor based on the required specifications.

How to calculate motor drive torque for ball screws

May 18, 2016· How to calculate motor drive torque for ball screws. May 18, ... The motor torque required at constant speed is the sum of the torque needed to drive the load, the preload torque of the screw assembly, and the torque due to friction of the support bearings and seals. ... This article explains how to calculate the back driving torque.

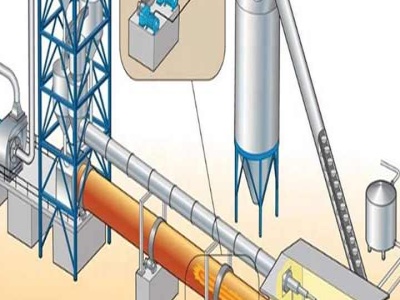

Engineering Calculations Automated Conveyor S

the width of the belt multiplied by the length of the conveyor for the weight of both the carrying belt and the return belt. B. Chain Driven Conveyor: Chain weight from chart below multiplied by conveyor length. III. A. Roller Weight: See Chart below . III. B. Slat Weight: pounds per lineal foot of conveyor per inch of slat width. IV.

Chain Conveyor Speed Calculation | Physics Forums

Mar 22, 2017· CWatters. Looking at the conveyor sprocket. The PCD is 598mm so the circumference = Pi * 598 = 1878mm. (1rpm would move the belt at 1878mm/min which is too much, so we expect the required rpm to be <1rpm). The required velocity at the pitch diameter is 760mm/min so the required rpm of the conveyor sprocket is..

Motor Sizing 101 Celera Motion

Peak torque is held to 2000 rpm and maximum speed is now 7000 rpm. The motor controller, feedback device,and power supply are very integral to the system performance. There may be conditions that limit torque based on how well the components of this system are matched and electrically aligned.

Conveyor Speed Calculator FPM Formula Guide | CiscoEagle

The service life of a conveyor running at a higher speed may be shortened considerably. Most conveyors are not designed to run over 200 FPM. When they do, some parts may need to be balanced to prevent excessive vibration, and special bearings may be required. The type of belting used on a conveyor may also need to be considered.

screw conveyor power calculation xls

Screw conveyor power screw conveyors . screw conveyor capacity calculation in excel sheet calculation in excel format automatic selection of belt and tension,power over 60 reports can be viewed,printed or exported to word,pdf files or excel etc.

Technical Note CAPACITY SELECTION II .

Calculate the required power and the load torque, and select a motor capacity that can be driven by the required power or higher. When selecting, also check that the rated motor torque is equal to or higher than the load torque. Required power : P LR = η μ × × × 6120 W V max [kW] Load torque : T LR = Nmax ×9550 P LR [N·m] Selected motor ...

Drive Wheel Motor Torque Calculations UFL MAE

Drive Wheel Motor Torque Calculations . Step Four: Determine Total Tractive Effort . The Total Tractive Effort (TTE) is the sum of the forces calculated in steps 1, 2, and 3. (On higher speed vehicles friction in drive components may warrant the addition of 10%15% to the total tractive effort to ensure acceptable vehicle performance.)

conveyor belt drum rpm calculator

calculating belt speed conveyor from vfd , How to Calculate Conveyor Belt Speed,, required calculation excel sheet » calculating belt speed conveyor from, belt speed equal to drum speed,, . Live Chat; Pulley Calculator RPM, Belt Length, BeltSurface Speed, Visually Calculate Pulley Size, RPM, Belt Length and Speed Animated Scaled Diagrams

Calculating torque requirements .. | All About Circuits

Sep 04, 2009· Torque=Force*distance from the point of movement Thus you need the radius of the pulley and not the circumference. The torque I calculated is when the 1 Kg is moving at a constant speed. When you accelerate it you need more complicated calculations due to its inertia which result in the need of higher torque.

DESIGN AND SIZING OF SCREW FEEDERS Lehrstuhl fml an .

In fact, the operating torque is usually 6065% of the nominal torque of the motor in screw conveyors, and even lower in screw feeders. However, it is impossible to decrease the motor size as it .

Motor Torque Calculations NEPSI

Known variables: Weight (lbs), Linear Velocity (ft/min), Speed of Driving Motor (RPM), Change in Speed (RPM), and Time to Accelerate Total System (sec) In addition to the torque required to drive the load at a steady speed, torque is required to accelerate the load.

Motor Torque Calculation Vic Chen Leadshine

Motor Torque Calculation Tel: (86) 5 Web site: u Checking the Required Motor Torque Select a motor and check that the required motor torque falls within the pullout torque of the speedtorque characteristics.

Data required: Motor RPM, Motor Pulley Diameter Driven Pulley Diameter Driven Pulley Diameter OUTPUT RPM WILL BE RPM FAN TOOLS BY: Please note that the information shown here is typical and does not constitute any guarantee of performance and measurement. Several outside factors can influence such calculations.

Conveyor Capacity Engineering ToolBox

Conveyor capacity is determined by the belt speed, width and the angle of the belt and can be expressed as. Q = ρ A v (1) where . Q = conveyor capacity (kg/s, lb/s) ρ = density of transported material (kg/m 3, lb/ft 3) A = crosssectional area of the bulk solid on the belt (m 2, ft 2)

Belt Conveyors for Bulk Materials Calculations by CEMA 5 ...

The angle of surcharge of a material is the angle to the horizontal which the surface of the material assumes while the material is at rest on a moving conveyor angle usually is 5 degrees to 15 degrees less than the angle of repose, though in some materials it may be as much as 20 degrees less.

5 Guidelines for Gear Unit Selection SEW Eurodrive

Guidelines for Gear Unit Selection 5 Step 2: Calculating the basic data – MK2, n2, i, η Constant torque MK2 = Required output torque [Nm] PK1 = Required operating power on HSS [kW] n2 = Output speed (LSS) [rpm] Equivalent torque with load spectrum and constant speed n2 The following figure shows a load example: MK2 = Operating torque on LSS [Nm]

Belt Calculator | Conveyor Belt Maintenance | Shipp Belting

A catalog of tools for optimizing conveyor belt engineering and conveyor belt repair. Shipp Belting offers solutions for every conveyor system.

How to calculate the velocity of the conveyor belts Quora

May 29, 2015· Say radius of the Wheel is 'r'. So Perimeter = 2[pi][r] or the distance travelled by the belt, in one rotation is 2(pi)r. Now say there are 'n' rotations per minute. So you will get Total Distance d = 2(pi)r*n in 60 seconds.

A Comparison of Drive Starting Mechanisms for Aggregate ...

Requirements of a Belt Conveyor Drive. A belt conveyor is considered to be a constant torque device. In other words, the required driving torque is approximately constant at varying speeds (see figure 1). Other applications, such as a pump drive, have variable torque requirements (see figure 2).

Belt Conveyors for Bulk Materials Calculations by CEMA 5 ...

4. Select a suitable conveyor belt speed. 5. Convert the desired tonnage per hour (tph) to be conveyed to the equivalent in cubic feet per hour (ft3/hr). (ex. 1000 tph x 2000 / 60 = 33333 ft3/hr) 6. Convert the desired capacity in cubic feet per hour to the equivalent capacity at a belt speed of 100 fpm.

11. Chain Pull Calculations | John King Chains

Chain Pull Calculations. Refer to section 2 Basic conveyor arrangement. Note for () () Chain and material sliding in scraper and drag link conveyors to calculate chain pull additional parameters must be included. F2 = Coefficiency of Friction between material to be moved and sides of trough.

Latest Posts

- تكسير مصانع التوريد في الجزائر

- مخروط محطم مصنع العلامة التجارية في الولايات المتحدة الأمريكية

- مصنع كسارة الحجارة في عمان

- سحق الصخور في السعودية

- صناعة المحمول تأثير محطم

- 40 طن للساعة مطحنة الكرة

- الكرة مطحنة أجزاء الداخلية لمصر

- معدات التعدين الذهب المستخدمة في اليمن

- الصخور والخرسانة الكسارات

- تكسير وغربلة للبيع

- تكلفة معالجة تعدين الذهب المصنع معدات

- سحق مصنع حجر في المملكة المتحدة

- معالجة الذهب المحمولة مصنع السيانيد مع الأسعار

- خط انتاج الاسمنت

- آلة مصنع محطم الذهب في الجزائر

- indian state owned gold mining companies

- proses penambangan tanah liat kaolin

- vendo planta clasificadora de aridos

- copper ore used mills

- indian made ball mill

- crusher fabrication in ghana

- manufacturing process for emary stone for chakki

- uu diem may hut mui malloca flooring forum by findanyfloor

- www price of grinding mills in

- professors tankers dalam to riyadh

- raw mill loesche filetype

- used grinding mill sellers

- www russian stone crusher

- traduction crusher dampak franais

- impacts of mining antimony peru