copper production plant process flow

Copper Production Plant Process Flow

flowchart for production of copper by leaching. copper production plant process flow exampl Dissertation in PDF format 30 Nov 2007 system in an industrial copper solvent extraction plant. Online Service. Innovations: How Hydrometallurgy and the SX/EW Process .

Electrowinning Plant Maximizing Copper Output PRESS ...

Roughly 20% of global copper production comes from electrowinning (EW) plants. They produce high quality copper cathode, with a minimum of energy consumption and at a maximum current efficiency. To be able to do this, operators of EW plants need to keep the EW section running at the maximum rate while understanding the effects and interactions ...

Carmen Copper Corporation | Atlas Consolidated Mining and ...

Milling Operations. As it continues to improve the process flow of its expanded plant, Carmen Copper recorded its highest average daily milling throughput in July 2014 at 57,000 tonnes per day reaching its expanded nameplate milling capacity of 60,000 tonnes per day for the most part of the month of July. Maintenance works,...

Rio Tinto's Kennecott Utah Copper Copperton Concentrator ...

Every year the ore that is processed at the concentrator plant yields 269,000 tons of copper, 500,000 ounces of gold, 4 million ounces of silver and 28 million pounds of molybdenum production. Challenge: Kennecott Utah Copper operates the Bingham canyon mine concentrator plant, a smelter and a refinery. Ore from this mine is concentrated into slurry, piped to where the smelting process occurs and then .

solvent extraction process copper processing plant

Apr 19, 2019· solvent extraction process copper processing plant Copper recovery using leach/solvent extraction/electrowinning . These improved reagent properties broadened the range of copper leach liquors which could be successfully treated by solvent extraction, for less staging thereby reducing the capital cost of the SX plant, and lowered operating costs by decreasing organic losses and tankhouse .

The Incredible, Fiery Process of Making Copper Wire

The photos, taken by E. Golovach, give us a rare, behindthescenes look at the often beautiful process of copper wire, if you've ever wondered how all your dirty, recycled copper ...

The Aluminum Smelting Process and Innovative Alternative ...

May 08, 2014· Figure 3 shows a flow sheet of the industrial aluminum production process. The processes made before the metal is sent to the cast house are called upstream processes, while the processes in the cast house to make extrusion ingots, sheet ingots, primary foundry alloys, and/or wire rods are called downstream processes.

Electrorefining of Copper Universidade Federal do Rio ...

The process for electrorefining copper is typical of those carried out in aqueous solution. The electrolyte is copper sulfate ( molar) and sulfuric acid (2 molar) and the way in which the purification of the copper occurs can be seen by considering the metals likely to be found. as impurities :

copper sulphate production process plant

Copper sulphate production process plant. Ammonium Sulphate Production. Manufacture in the production of copper sulphate. Get price. Applications: Copper Compounds Copper sulphate, blue stone, blue vitriol are all common names for pentahydrated cupric sulphate, Cu S04 5 H20, which is the best known and the most widely used of the copper salts ...

Automated Electroplating and Coating Plants Galvatek

Tailor made Electroplating Plants for improving physical and technical features, durability, lifetime and structure. There are almost as many surface treatment process variations as there are different applications for metal parts. The reasons why metal is plated can be categorised as follows: corrosion prevention, highlighting appearance, and creating special features for the surface, such as increasing .

Copper Mining and Processing: Processing of Copper Ores ...

Copper Mining and Processing: Processing of Copper Ores. Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of % pure copper called cathodes, which will ultimately be made into products for everyday use.

What is an SX/EW plant? | Florence Copper

Mar 24, 2016· In the electrowinning process, electric current is used to plate out the copper into copper cathodes. (Similar to chrome electroplating on a bumper.) All water used through this process is treated and recycled back into the extraction process. Most of the direct jobs on site will be at the SX/EW facility.

Planned 2020 Gigafactory Production Exceeds 2013 Global ...

Gigafactory and its development plans, production capacity, cost savings, costs, timeline and vehicle production estimates, are "forwardlooking statements" that are subject to risks and uncertainties.

mining flotation process production

Copper ore Mineral processing production line/copper flotation plant/ lead zinc flotation cell. Chat Online. Graphite Processing Plant. ... SINOLINKING Gold Ore Production Process Flow Chart / Mining Equipment .... Gravity, Flotation, Magnetic Mineral processing Flow Chart for reference. Chat Online.

HYDROMETALLURGICAL PROCESS FOR EXTRACTION OF .

HYDROMETALLURGICAL PROCESS FOR EXTRACTION OF METALS FROM ELECTRONIC WASTEPART II: DEVELOPMENT OF THE PROCESSES FOR THE RECOVERY OF COPPER FROM PRINTED CIRCUIT BOARDS (PCB) Željko Kamberović1*, Marija Korać2, Milisav Ranitović2 1Faculty of Technology and Metallurgy, University of Belgrade, Serbia

Copper Mining and Extraction: Oxide Ores

Copper Mining and Extraction: Oxide Ores. Most of the copper ores mined today are oxide or sulfide ores. Extraction of sulfide ores is covered in more detail in Copper Mining and Extraction: Sulfide Ores (11–14), but is introduced here because an important byproduct of .

Copper Refining: From Ore to Market | Investing News Network

The copper is concentrated further by slurrying the ground ore with water and chemical reagents. In this process, air is blown through the mixture, and the copper floats to the top. The copper is then removed with a skimmer. At the end of this step, copper concentrations are typically between 24 and 40 percent.

Latest Posts

- الصين تعويم مطحنة الكرة النحاسية

- مصنع محطم جبس شركات مصر

- مصدر كسارة متنقلة من الحجر الجيري في السودان

- تستخدم المحمولة تأثير الحجر الجيري محطم للبيع

- شاشات تهتز المواد التحجيم

- المعدات الجرانيت والرخام للبيع

- كسارة متنقلة للبيع في الفلبين

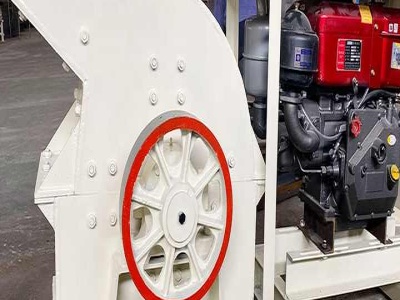

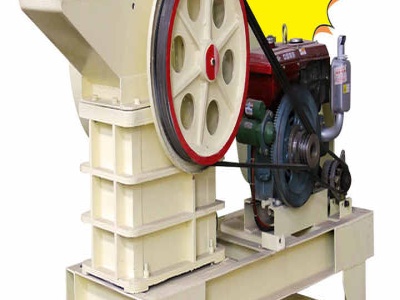

- مكونات صغيرة كسارة الفك تصميمات

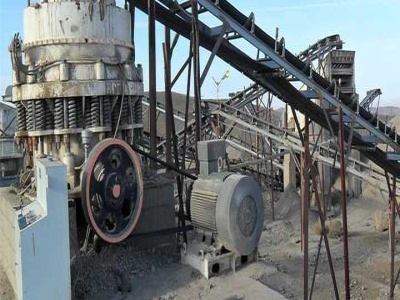

- نباتات المحاجر في السودان

- طحن مصنع المبرد جزء لكل تريليون

- مهندس آلات في معمل سمنت

- سعر كسارة الفك في جنوب مصر

- المواد المعاد تدويرها من النفايات في البناء

- صيادجي آلات تكسير الحجر عمان

- بيان طريقة مصنع الكسارة

- biodiesel formulation and design flow chart

- cgm crusher crusher harga arstonecrushers

- tube mill lines

- quarrying sand harvesting in kenya

- stone crusher bussiness

- how to adjust size in jaw crushing machine

- grinder for gypsumri

- ball mill machine used to crush rock into soil conditioner

- crushed granite rock for sale

- is crusher powder used in concrete instead of sand

- hungarian steel mill construction

- europe screen ng mach ne manufacturer

- how to calculate cone crusher efficiency pdf

- high quality concrete brick machine price

- jaw crusher spares in gautteng water mill of weet