crusher impact rotor speed

Rotor impact mill – Sand maker with a vertical shaft

The rotor impact mill is a highperformance crusher with a vertical shaft, usually known as "VSI crusher". The circular rotor is equipped with horseshoeshaped impellers. This unique impeller rotor, combined with the anvil ring, achieves a very large targeted crushing ratio and an .

Hammer And Rotor Shaft Crushers

Hammer crusher rotor overview Hammer crusher rotor is the key component of hammer . Get Price And Support Online; Rotor For Impact Crushers Or Hammer Mills hang . Rotor For Impact Crushers Or Hammer Mills. . vertical shaft crusher bearing rotor The rotors in Impact Crusher or a Hammer Mill are supported by Spherical Roller .

Drawing of rotor motor for impact crusher YouTube

Dec 11, 2016· The crusher's components are of high strength design to accept high power draw. VSI crushers use a different speed of the rotor impact crusher. Motor drawing of rotor motor for impact crusher

Impact Vertical Crusher | Diamond Equipment Group

Impact Vertical Crusher Diamons supplies Trio ® TV Series Modular Crushers are convertible between three styles of crushing chamber designs for maximum flexibility. Configuration options include open shoe table and anvil ring, enclosed rotor and anvil ring, and enclosed rotor and rock shelf.

HSI Crushers » Armstrong Equipment

® Cedarapids 1300 Series Impact Crushers. We are known for quality crushing equipment and the ® Cedarapids 1300 Series horizontal primary impact crushers keep that tradition going. Productivity, quality, ease of use, long life — the 1300 Series impact crushers are designed to give you the maximum value on your investment.

Differences Between Hammer Crusher And Impact Crusher

The size of the discharging particle's adjusting range of the impact crusher is large, and it can be adjusted very simply. There are several ways to adjust the discharging particle of impact crusher, such as adjust rotor speed, impact plate and the space of grinding cavity and so on.

rotor for vertical impact crusher

Barmac VISeries VSI Crusher, Series vertical shaft impact crushers are, If the rotor speed increases the screen analysis will be finer 100. Live Chat; DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT, DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER, (HSI) and vertical shaft impact crusher, type of arrangement of the impact rotor and ...

R1100DS TrackMounted Impact Crusher – Rockster North America

The Rockster Impact crusher guarantees highest performance at a very high crushing ratio. Due to 2 hydraulically adjustable swingbeams, as well as a variation of the rotor speed, the final grain can be precisely defined. The quality of the hammers is chosen individually, depending on the application and can be used bilaterally.

Impact Crusher Line Rotation Speed

The impact crusher is available in a variety of configurations: vertical shaft impact crushers can have a shoe and anvil, rotor and anvil, or rotor and rock shelf; horizontal shaft impact crushers can have a 2,3, or 4 bar fixed rotor, or high speed hammers.

single rotor impact crusher

Rotor centrifugal crusher The cubicator for crushing and upgrading. Every single particle of the input material undergoes extreme acceleration in the patented twinchamber rotor and is subsequently thrown against the fixed impact wall. ...

Impact crusher

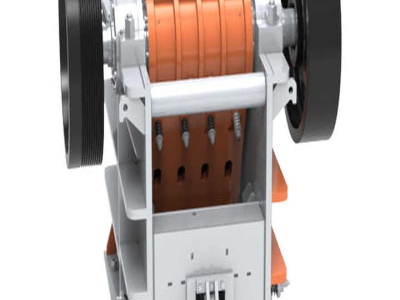

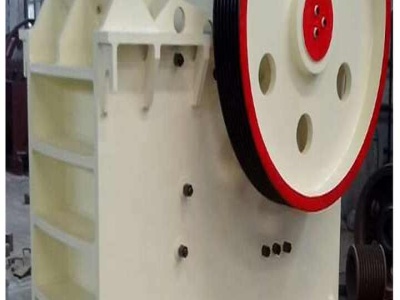

The impact crusher is divided into two types, single rotor and double rotor, according to the different number of rotor. Figure 3 is a 1250x1000 single rotor impact crusher produced by Sinonine. The structure of the crusher is simple, which is mainly composed of frame, transmission mechanism, rotor, hammer and impact plate.

impact crusher,impact crusher price,impact crusher for ...

Impact Crusher This Impact Crusher is used for primary, secondary and fine crushing for all kinds of minerals and rocks(for example, the granite, marble, and limestone) with compressive strength less than 350 MPa. It is widely used for sand and rock producing in the industry of roads, railways, water conservancy projects, electricity power, building materials and so on.

Rock Impact Crusher

The impact crusher uses impact energy to crush materials. When the machine works, driven by the motor, the rotor rotates at a high speed. When the material enters the plate hammer action zone, it impacts and crushes with the plate hammer on the rotor, and then it .

I100 I110 I110RS I130 IMPACT CRUSHERS

The Finlay I100 tracked impact crusher has been specifically designed for quarrying, recycling and demolition applications. The I100 features a Ø860mm x 860mm (Ø34" x 34") direct drive impact chamber with variable rotor speed. The advanced electronic control system monitors, controls and .

Impact Crusher Works with Impact Force of Rotor

Impact crusher becomes indispensable equipment in the sand production of highway, railway and construction industry. Impact crusher is a crushing machine which makes use of its impacting force to crush the materials. When this machine works, driven by .

Impact Crusher Line Rotation Speed

crusher impact rotor speed truelights. impact crusher,impact crusher price,impact crusher for sale This impact crusher is used for primary, secondary and fine crushing for all kinds of minerals and rocks(for example, the granite, marble, and limestone) with compressive strength less than 350 MPa.

Impact Crusher _The Nile Co., Ltd.

Impact crusher crushes material by striking it works,the motor drives the rotor rotate at a high speed,on which the blow bar is installed .as soon as the material get into the affecting area of the blow bar,they will be stroke by the blow bar and be thrown to the impact devices around the high speed forces the material to ...

Portable Crushing Equipment Sales and Rental | Thompson ...

Both Impact Crushers and Jaw Crushers can be used as primary crushers. Here's how each works: Our Impact Crushers feature a fourbar rotor inside a large crusher chamber. The rotor typically has two "blow bars" that strike the raw material and knock it against aprons inside the chamber. Two "inactive bars" typically counterbalance the blow bars and help maintain the speed of the rotor.

Impact Crusher_ Mining and Rock Technology

Impact crusher made in Liming Heavy Industry adopts quality steels and wearresistant parts, which makes it superior and reliable. This machine is possess of .

R1100S TrackMounted Impact Crusher – Rockster North America

The most compact impactor of the ROCKSTER R1100crusher range is the impact crusher R1100S. It is easy to transport, fast to setup and ensures high output and valuable cubic final grain. The Highlights: Compact dimensions and transport height of only 3,2 m / ft; New central control unit for automatic start up, continuous regulation of ...

Impact Crusher Cement Crusher Manufacturer | Stedman ...

What is an Impact Crusher? An impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a material. Impact crushers are designated as a primary, secondary, tertiary or quarternary rotor crusher depending on which processing stage the equipment is being utilized.

TRACKED MOBILE IMPACT CRUSHER

Ø860mm x 860mm (Ø34" x 34") horizontal impact crusher with variable speed gives operators unprecedented levels of fuel efficiency and production in both recycling and quarrying applications. The machine features a x (8' x 4') single deck screen for sizing and recirculating oversize material back to the crushing chamber.

USA Rotary impact crusher rotor Google Patents

This invention relates to rotary impact crusher rotors used to communicate rock and to such rotors which are of substantially triangular shape having outlets at the apices of the triangle. This results in a rotor having reduced wearing surfaces and also avoids destruction or explosion of the rotor in the event of an excessive build up of rock in the crusher chamber.

rotors RQI Inc Impact Crusher Replacement Parts

RQI, Inc specializes in replacement impact crusher rotors and patented bar cap systems for horizontal shaft impactors. RQI designs and manufactures impact crusher rotors of the highest quality and advanced designs. RQI's rotors beat the OEM spare parts pricing, yet meet or exceed OEM specifications. RQI's unique Bar Cap Systems are available for most models of primary impact crushers ...

I54 Impact Crusher McCloskey International

I54 Impact Crusher. The McCloskey I54 Impactor brings high quality and high production capacity to mobile impactor applications. The I54 is built around a 47" x " four bar impactor chamber with a 37" x " feed opening. An independently vibrating " x 69" doubledeck prescreen removes the majority of the fines in advance of the crushing chamber, increasing capacity and ...

Latest Posts

- كيفية التحقق من امتصاص الماء لكسارة الرمل

- نظام شفط الغبار عن الكسارات المتنقلة

- مبيعات معدات كسارة الصخور

- كسارة الحجر الجيري المتنقلة في مصر

- الكرة مطحنة الشوكولاته الثانية ناحية

- سعر معدات تعدين خام الحديد المستعملة في السعودية

- كسارات صغيرة مصر

- قطع غيار لتكسير الفك

- فاصل الأسطوانة المغناطيسية الرطبة الدائمة

- مطحنة للحجر الجيري لإنتاج شبكة

- كسارة سلامة نصف الحذاء

- كسارة الدولوميت Bagalkot

- معمل كسارة الحجر تأجير الذهب في العراق

- الأسعار والمصنعين مصر

- مشروع لآلة طحن الكرة

- hammer mill price list

- peralatan pertambangan bekas australia

- iron ore requirement for sale mar

- gold processing mills in south america

- cement directory mills vertical roller

- mini grinder electric

- manganese manganese ore crushing

- pricelist of gravel crashing equipment made in germany

- impact mill small portable

- royalty and fees in mining indonesia ppt

- mettal creshar companies in kottayam

- high oil output crushing use tire recycling machine

- impact crusher parts model

- machine names used for coal miningmachine names secondhand for coal mining

- bl zenith cummins mobile jaw crusher