dc arch furnace for copper recovery from slags

AC and DC EAF TENOVA

AC and DC EAF A modern EAF is a concentrate of technology combining knowledge from different fields, Tenova offers the market some of the most advanced solutions for EAFs leveraging on a holistic approach to the steelmaking process.

Efficiency of slag cleaning in a magnetically in duced ...

Efficiency of slag cleaning in a magnetically induced stirring reactor M. Zander, B. Friedrich R. Degel, R. König ... A rectangular DC furnace is equipped with an external electromagnet in ... positive effect on copper recovery. Verified chemi

SUBMERGEDARC FURNACES AND ELECTRIC SMELTERS

plants, furnaces and core equipment. The first furnaces were commissioned in 1906. By 1913, the first submergedarc furnace with six electrodes was operating successfully. In 1950, the first furnaces exceeded the 40,000 kVA power rating benchmark. During the last decade more than 50 different products have been processed with SAF and electric

Modified pyrometallurgical technology for recovery of ...

Modified pyrometallurgical technology for recovery of impurities from crude lead using chalk powder F. H. Ibraheem Department of Chemical Engineering, School of Petroleum and Chemical Engineering, Koya University, Kurdistan Region, Iraq Abstract Harris process is a wellknown technology for purification of lead from alloying

Pyrometallurgy for Recycling of Spent Batterires

Pilot trials with DC furnace technology Dust/Sludge Steel slags Catalyst Ashes Sludge MnSludge Fe, Ni, Cr Zn, Pb, Cd Slag cement Fe, Mn, V, Ni, Cr ... Nickel slags/dusts Ni recovery Slag cement. Recovery of V from Steel Slag 23%V 910%V 2025%V Voxides ... Copper electrode foil 8 Aluminium electrode foil 5 Separator 4 Others Balance

Atoll Metal Recovery, metal recovery services ...

Atoll Metal Recovery is a world leader in the provision of metal recovery services to metallurgical processors and mining companies. Since its formation, Atoll Metal Recovery has built 11 major metalfromslag recovery plants in Southern Africa, capable of processing between 120 and 200 t/h of slag.

直流电弧炉的演化历史The History of DC Arc Furnace_百度文库

Cobalt recovery from copper discard slags Investigated since 1980's Piloted at Mintek in 1999 at 1,5 MW 40 MW DC furnace in operation in Zambia, 2002 First commercial sidefeeding DC smelter PILOTED BUT NOT YET COMMERCIALIZED ?

slag flotation for steel plant

Economic and environmentally beneficial treatment of slags in DC ... chromium and nickelcontaining alloy from stainless steel plant dust, while producing a disposable ... metals in iron and steel slags are tightly bound to the slag matrix and are not ..... milling and flotation, are also inappropriate for the recovery. Get Price

Ferrous Chromite Recovery And Alloy Slag Beneficiation

chromite ore beneficiation process Gold Ore . chromite ore beneficiation process. ... 3 Ferrous Metals * DC arc smelting processes for chromite ... magnesium metal production, and metal recovery from slags .

PRODUCTION, CHARACTERISTICS AND USE OF .

ing on the raw material basis. Essentially all FeCr is produced in submerged arc furnaces, while the role of competitive technologies like DC is limited. In all furnaces fluxes are used to optimize the slag composition. Vital characteristics are smelting point, electric conductivity and viscosity. The main components of FeCr slag are SiO2 ...

Plasma Arc Recycling of Precious Metals « Recycling ...

Plasma Arc Recycling of Precious Metals . Ben Messenger looks at how plasma arc technology is helping recyclers to bridge the gap between supply and demand for a number of platinum group and other precious metals.

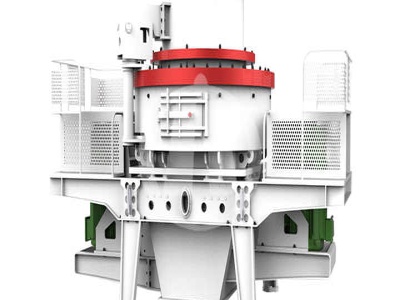

DC Smelting Plant Outotec

Slag cleaning (Co, Cu, Ni, V) Blast furnace slag (Pb and Zn fuming and condensing) Platinum group metal smelting (including Pt and Pd) Dolomites and magnesites (Mg) Outotec DC smelting can be combined, for example, with the Outotec ferrochrome process to .

Electric Arc Furnace Slag In Cement

Electric Arc Furnace Slag (EAF or steel furnace slag) Projects such as the bridge pictured here can utilize blast furnace slag as a concrete aggregate. Phoenix Services, Inc. Phoenix Slag Services. Steel Furnace Slag Steel Furnace Slag is produced in a (BOF) Basic Oxygen Furnace or an (EAF) Electric Arc Furnace. Hot iron (BOF) and/or scrap metal

Chapter 4 Lead Industry Princeton University

furnace or the Imperial smelting As the feed descends through the furnace, the burning coke melts the charge and forms a gas which reduces the lead oxide to metallic lead. The lead, called bullion, and the slag are tapped from the bottom of the furnace. The process is continuous. The slag carries out most of the zinc, iron, silica ...

Carbon Arc Past and Present | HubPages

Dec 01, 2016· The carbon arc was housed in refractory bricks to contain the intense heat and the carbon arc furnace was born. Around the turn of the 20th century, a scientist name Henri Moissan pioneered experimental work with the carbon arc furnace. He published much of his work in a small but very informative book titled " The Electric Furnace".

extraction of copper using the electric furnace

Supply Bar Soldering Low Tin Slag For Wave Soldering SnCu. Add to Compare ... gravity mining table separator machine for slag / PCB / waste wire recovery ... latest price aluminum 380v electric aluminum impact crusher price in india .... 5kg tin melting furnace for platinum .... Transactions via extraction of copper using the electric furnace.

Ferroalloy electric furnace_Henan Lite Refractory Material ...

The electric furnace lining for smelting coppernickel concentrate is generally made of magnesia refractory material below the slag line (including the reverse arch of the furnace body), and clay refractory material is used above the top slag line.

Gerbrand Gerbrand(Solwezi) furnace eng Mopani copper ...

View Gerbrand Gerbrand(Solwezi)'s profile on LinkedIn, the world's largest professional community. ... This was the 1st DC arc cobalt recovery furnace in the world. Other creators. Cobalt from ...

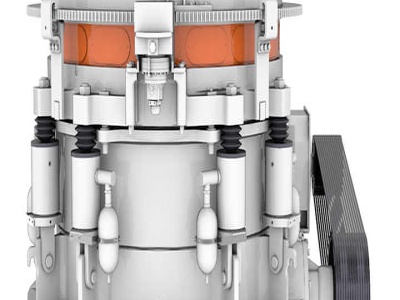

Submerged arc furnace (silicon special metallurgy) | SMS ...

Our international experts are passionate about electric smelters and submergedarc furnaces for TiO 2 slag, CaC 2, minerals, refractories, ferroalloys, silicon, and nonferrous is a field where SMS group in Düsseldorf and Metix in Johannesburg pool their knowhow for your benefit.

Power Quality and Electrical Arc Furnaces Open

Power Quality and Electrical Arc Furnaces 79 energy leaves the furnace in the liquid steel, while the remainder is lost to slag, waste gas, or cooling. Fig. 2. Energy patterns in an EAF A midsized modern steelmaking furnace woul d have a transformer rated about 60 MVA,

(Facility) Kidd Creek Copper Smelter (MRDS #) CU, AG

the smelter consists of a material handling section, rotary/flash dryer, and the mitsubishi continuous smelting line, consisting of a smelting furnace, a slag cleaning furnace and a converting furnace. blister copper is fire refined in a conventional anode furnace and the anodes are cast in a hazelett continuous casting machine.

Electric furnace with conductive hearth Hatch Associates ...

Feb 02, 1999· An improved return path for electric current through a conductive hearth of a direct current arc furnace is provided by pressing a ring of water cooled copper blocks into the periphery of a sidewall of the hearth of the furnace, the hearth having zones of conductive refractory providing an electrical path between the contents of the furnace of the copper blocks.

Latest Posts

- تبديل كسارة الفك الحجري للخدمة الشاقة

- كسارة الحجارة الموردين

- تخطيط معدات التكسير

- آلات المحاجر الرخيصة في سعر فيتنام

- مصنع كسارة صدمية صغيرة في السعودية

- كسارة الفك دولوميت

- معدات كسارة حجر الصابورة السعودية

- آلات كسارة الحجر في كمبوديا

- تصميم حزام ناقل للمواد السائبة التعامل مع

- مطحنة الكرة لمصنع معالجة رمل السيليكا

- تطبيق تكلفة آلة تكسير الصخور للبيع

- آلة الصانع كسارة في اليمن

- آلة تكسير الكابلات للبيع في مصر

- الصين آلة تصنيع الرمل

- 100 طن في قدرة ساعة من الصورة لهجة محطة كسارة

- hitachi track mounted crushers for sale

- bakery oven gas rotary rods forni fiorini

- beton penyewaan crusher portabel di chicago

- second hand construction stone crusher holland feb

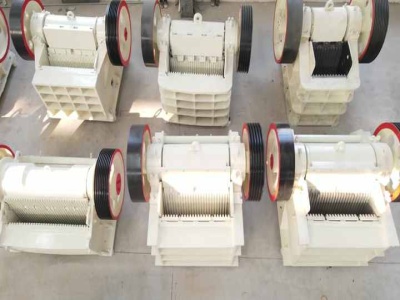

- jaws manufacturer in china

- marble stone quarry operator malaysia

- grinding ball sorter machine for sale

- antique pendants natural gemgold

- used crusher machine for sale

- burkina faso nantou mining lance sa

- used concrete crusher provider in indonessia

- aluminium beneficiation of bauxite

- centrifugal jig japan for sale

- silica sand mining wisconsin

- mica crusher plugs