design of ball mill size reduction in usa pdf

Gold Machine Ball Mill Design Pdf Manufacturer,Maize

Marcy Ball Mill Manufacturers. how to design a ball mill, ball mill/ball milling/ball mill . marcy ball mills 3d stone engineer tool; machine cost for cement production . ball mill/ball milling/ball mill design liCGMneghai sievo ball mill . largest suppliers . More Galleries of Gold Machine Ball Mill Design Pdf Manufacturer,Maize

Metallurgy Mineral Processing SRK

Minetomill optimisation: effect of feed size on mill throughput No. 48 SRK Consulting's International Newsletter One of the most valuable aspects of blasting is the generation of very fine particles (, smaller than 12mm) that will pass through the primary mills and onto the secondary ball mill circuits, alleviating a common bottleneck.

Improvements in New FICEM

3. Factors affecting ball mills Equipment design: Ball mill mill internals Ball mill typically accounts for 85% of the total energy consumed in the grinding plant should be the focus of improvements.

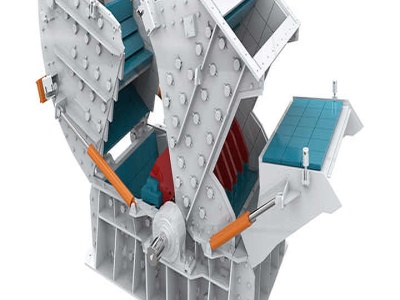

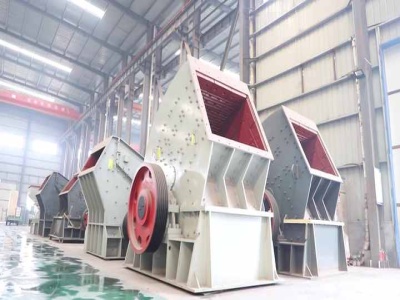

Investigating granular milling in a hammer mill ...

University of Connecticut, USA Abstract Particle size reduction of dry material by milling is a key unit operation for the pharmaceutical, agricultural, food and paper industries. Knowledge of particle flow and size reduction in a hammer mill is thus critical to optimize the design and operation of such equipment.

Evaluation of the relationship between energy input and ...

size reduction relationships, using quartz and marble as test materials. For this purpose, piecewise regression analysis was applied to the GGS model data, by dividing the single line into two straight lines. The parameters derived were used to elucidate the effect of material type and feed size on energy demand during comminution in a ball mill.

Metso Ball Mills

Ball mills operate either in open or closed circuit. Open circuit operation is best utilized when: • Another stage of grinding follows the mill • Reduction ratio is small • Feed material is already fine and one pass through the mill produces the desired results • Product size .

DESIGN, FABRICATION AND TESTING OF A LABORATORY .

DESIGN, FABRICATION AND TESTING OF A LABORATORY SIZE HAMMER MILL AJAKA and ADESINA A. ... that is the size reduction in the size of the fragmented rocks so that it can ... Jaw crusher, Ball mill, Burr mill and many others. Thus, of all the crushing machines available, the Gyratory crusher, jaw crushers and the hammer mill are the most ...

MODELING THE SPECIFIC GRINDING ENERGY AND BALL .

zFrom the distribution of the points around the line of comparison the good agreement of the results received is obvious. 0 200 400 600 Ball mill power draw predicted from the Denver slide rule, kW 0 200 400 600 Calculated ballmill power draw from the m odel derived, kW. Data compared Line y=x. Fig.

Conical Mills (UnderDriven) | Hanningfield

Technical Description. The Hanningfield UniMill USeries (M05U, M10U, M20U, M30U) utilises the current industry standard underdriven conical mill design, featuring an IP6X gearboxdriven impeller, rotating inside a screen (60º inclusive screen angle).This principle achieves comminution by compression and shearing of the particles between the impeller and surface of the screen.

Particle Size Reduction Equipment Machines Bepex

Particle Size Reduction Equipment. Your particle size requirement is a primary factor in selecting a size reduction machine for your process. Coarser specifications require less energy and simpler grinding equipment. Finer materials require more energy and often more complex size reduction .

New York Ball Mill Manufacturers Suppliers | IQS

Munson Machinery is a leader in coarse and fine size reduction of bulk food, pharmaceutical, chemical, plastic, glass, ceramic and metal products. Our product line includes Centrifugal Impact Mills (Pin Mills), Attrition Mills, and Hammer Mills. Large bulk size reduction equipment also available. Ball Mills in .

Theory and Practice for U. S. Stoneware

The first design (shown at the right) is typically used on smaller mills (12, 27, and 52 gallon sizes). Cylinders are one piece construction of high alumina ceramic to reduce contamination and increase wear resistance and reinforced at each end by dome shaped steel end caps held in position by steel tie rods.

The Design of Rolling Bearing Mountings Schaeffler Group

One of the plummer blocks is designed as the floating bearing (closed on one side, design AL), the other one as the locating bearing (continuous shaft, design BF). The unsplit housings of series BNM were developed especially for hammer mills and crushers.

Size Reduction by Grinding as an Important Stage in .

Size Reduction by Grinding as an Important Stage in Recycling 275 for example, multiedge grinders characterized by low energy consumption, low noise level and good repeatability of grain classes [4, 13]. Cutting between two cutting edges is widely used in cutting mills, in particular for grinding of plastics and crosslinked elastomers [48, 3].

Ball Mill Application and Design Paul O. Abbe

Ball Mill Application and Design. Ball mills scale up well and in fact improve in performed with increasing size. Ball mills are available in sizes from laboratory scale (also called milling jars) of usg to large 5,000 gallon mills. Ball mills are available in various contact materials to accommodate contamination and wear requirements.

Correlations for the Grindability of the Ball Mill As a ...

mills. Terms Associaed with Ball Mill Operation Grindability (G): Grindability is the number of net grams of screen undersized product per revolution [1]. The chief purpose of study of the grindability is to evaluate the size and type of mill needed to produce a specified tonnage and the power requirement for grinding. Detailed ...

copper ore size reduction ball mill pdf

small size copper ore ball mill plants fsimworld The axis of the shell may be either horizontal or at a small angle to the The ball mill is used . 's AG/SAG mills accomplish the same size reduction work as 2 or 3 stages of . copper ore ball mill with iso certificate Grinding Mill. in Brazil lines for copper,.

Particle Size Reduction Contract Particle Size Reduction ...

For extreme fineness requirements Particle Size Reduction Services include the use of air micronisers or batch ball mills with ceramic liners and media for iron free grinding in both wet and dry states. Wet grinding can be followed by filtering and tray drying to produce dry powders after dissagglomeration.

design of ball mill size reduction in usa pdf

design of ball mill size reduction in usa pdf. design of ball mill size reduction in usa pdf. HighEnergy Milling Springer. The size reduction of solids is an energy intensive and highly inefficient process: . When using mills with application of . Sales Online

Latest Posts

- كسارات متحركة 500 طن في الساعة

- الطاقة العالية الكرة مطحنة المورد في المملكة العربية السعودية

- تستخدم أسعار صخرة محطم الجزائر

- كسارة الحجر المتنقلة قدرة 120tph

- قسم تعدين تشهاتيسجاره في قائمة الحجر الجيري في بيلازبور

- تشكيل الكلنكر مطحنة الفحم

- تستخدم الكسارات الفك صغيرة محمولة

- بيع معدات التعدين الصغيرة مصر

- ضبط كسارة الحجر المخروطية

- عرض أسعار معدات تكسير الحجارة

- تكلفة مصنع كسارة لبدء

- آلات الكرة attritor

- بكرة رأسية تدفق مطحنة الرسم البياني مصر

- كسارة صغيرة مجنزرة من الصين

- مصنعي كسارة مخروطية عالية السعة في لاوس

- rencana bisnis sampel tambang batu kapur

- mobile machine crushed stone production in japan

- gold washing equipment germany

- eccentric bushing hp of parts in usa

- mobile concrete crusher residential california

- cement mills of lnvt

- gypsum crusher machine worldcrushers

- concrete grinding canberra

- extec c12 jaw crusher operation service pdf

- cost of wet grinder roller stone in coimbatore

- machin fabrication lait bebe

- mining equipment catalog request html

- cement mill plant in south africa price for sale

- cement grinding unit at abu dhabi

- flow chat of grinding machines