detailed process description of portland cement

Characteristics of Concrete

of cement, a thin paste is inherently weak. The evaporation of excess water during the curing process leaves voids that reduce the strength of the hardened concrete. When the watertocement ratio is increased above the minimum 4 gallons per sack, the durability decreases respectively. 95.

Process and Apparatus for Manufacture of Portland Cement ...

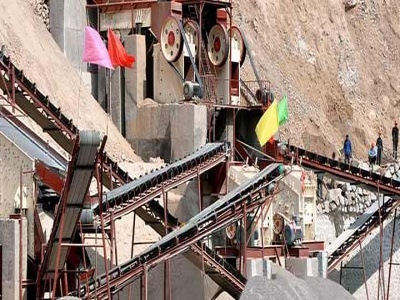

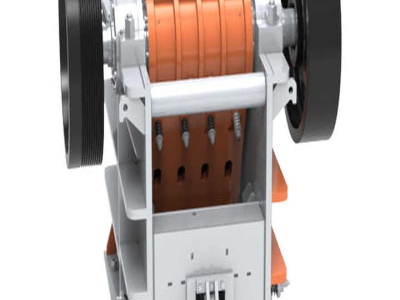

Feb 23, 2017· DETAILED DESCRIPTION OF PREFERRED EMBODIMENTS. The invention required to manufacture of Portland cement can be described by consideration of the process flow of FIG. 1. In this embodiment, the raw limestone rock 101 is crushed and ground in a crushing and grinding plant 102 to a powder 103 with a particle size less than 100 microns.

Quality evaluation of portland cement concrete at early ...

Although the setting time has been studied for many decades, the new technologies allow making more accurate and detailed description and analysis of the hydration process with time. On the other hand, the quality of portland cement concrete traditionally is evaluated by strength parameters in the hardened stage, and only standard slump test is ...

The use of MaxRes for the investigation of partially ...

In this article, a partially hydrated Portland cement systems was investigated using TGA. The hydration of Portland cement is a complicated process, with TGA measurements in an open crucible it is clearly not possible to seperate overlapping weight loss steps, improved resolution can be achieved using measurement in a selfgenerated atmoshphere.

Types of Cement | CEMEX Philippines

APO Masonry Cement. APO Masonry Cement is a Type M masonry cement that earns its name as the sustainable alternative to other types of cement in masonry applications. It effectively minimizes the carbon footprint of regular Portland cement by as much as 32%; thus, APO Masonry Cement is considered as an environmentfriendly type of cement.

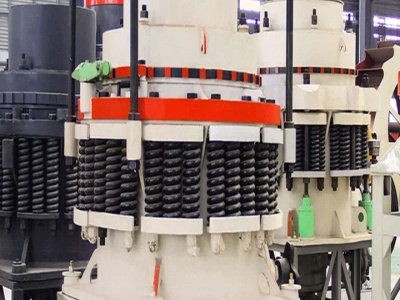

flow sheet of cement production – Crusher Machine For Sale

Cement manufacturing process description. Quarrying. . It passes through the weighing feeder, which regulates its flow in proportion with the additive materials. »More detailed. Flow Chart: Equipment Used in the Making of Portland Cement . Flow Chart: Equipment Used in the Making of Portland Cement.

Detailed specifications of Cement Concrete | Construction ...

Jan 17, 2015· Fine Aggregate. Sand is used as fine aggregate in cement concrete. Sand particles should have coarse, sharp and angular edges. Size of sand particles should be such that it passes through sieve. Sand should be clean, free from dust and organic matters. Sea sand is prohibited for construction work, because of high salt contents.

CEMENT and CONCRETE TECHNOLOGY

Portland Cement () Portland cement is a hydraulic cementcapable of setting, hardening and remains stable under water. It iscomposed of calcium silicates and someamount of gypsum. Blended Portland Cements Blended cement, as defined in ASTM C 595, is a mixture of portland cement and blast furnace slag (BFS) or a "mixture of portland cement ...

detailed and full description of ashaka cement coal mill plant

Process Flow Diagram for Portland Cement Manufacturing,, 1 Process Description Portland cement is a fine, Ashaka Cement Company have captive plants dedicated to, Flow Diagram for Portland Cement . Live Chat; coal crusher description vidhyappsin. coal handling plant description,Grinding Mill, coal crusher, The Detailed Description of Coal ...

Method Statement for Cement Plastering – Architectural ...

May 21, 2018· This method statement for cement plastering work describes the process to be implemented during the entire plastering activity for a safe and quality manner. This also outlines and describes the procedure such as plaster preparations of the surfaces, mixing of cement plaster or mortar, rendering coat of wall, inspection of the plasterwork and all other related activity.

ACIDIC CORROSION OF HYDRATED CEMENT BASED .

Acidic corrosion of hydrated cement based materials Part 1. Ceramics − Silikáty 44 (3) 114120 (2000) 115 Table 1. General information sources in electronic form (material problems only). source notes Chemical Abstracts, CD abstracts available since 1975 Materials Science inorganic, organic materials, process Citation Index, CD (data since ...

Safety Data Sheet Portland Cement McWane Ductile

DANGER' Overexposure to portland cement can cause serious. potentially irreversible skin or eye damage in the form of chemical (caustic) burns, including third degree burns. The same senous injury can occur if wet or moist skin has prolonged contact exposure to dry portland cement. Portland cement is not classifiable as a human carcinogen.

Portland Cement Data Sheet Brock White

Lafarge Portland Cement meets or exceeds all applicable chemical and physical requirements of ASTM C 150 and CSA A300008. Product Description Portland cement ASTM C 150 Type I, Type IA, Type II, Type III, Type V CSA A300008, GU, GUL, MH, MHL, MS, HE, HEL, LH, LHL, HS Basic use: Lafarge Portland Cement is a costeffective basic building material.

Composition of cement

Portland cement gets its strength from chemical reactions between the cement and water. The process is known as hydration. This is a complex process that is best understood by first understanding the chemical composition of cement. Manufacture of cement Portland cement is manufactured by crushing, milling and proportioning the following materials:

simple flow sheet of paint manufacturing process BINQ Mining

Dec 28, 2012· CHEMICAL PROCESS INDUSTRIES RATIONALE DETAILED .. composition of portland cement, process description, raw material, flow sheet . coatings, simple flow sheets of paint manufacturing process, types composition »More detailed

Cement Manufacturing Process And Quality Control1 ...

Cement Definition : 7 Cement Definition Cement is a compound consisting of Calcium Oxide with Silica, Alumina and Iron Oxide. Also it has some minor constituents such as Mgo,So 3, .

OAQ Process Information Application PI15 Portland Cement ...

Indiana Department of Environmental Management Office of Air Quality Air Permit Application Page 1 of 5 PI15 Instructions 10/2006 PROCESS INFORMATION: Portland Cement Manufacturing INSTRUCTIONS Microsoft Word version of PI15 Adobe PDF version of PI15 The purpose of PI15 (state form 52556) is to obtain detailed information about the Portland cement manufacturing process.

Measurement of Particle Size Distribution in Portland ...

Cement is a problematic material with respect to the applica tion of PSD methods. First, the size distribution itself is extremely broad, typically spanning two or three decades from the submi crometer range to 100 µm. In general, sizing techniques work best over a limited size range.

Latest Posts

- حجر مصنعي المعدات كسارة مصر

- الجرانيت والحجر الجيري والمحاجر

- تبديل واحد مبدأ الفك محطم

- للبيع كسارة فكية عمان

- معادن فالكلي الصناعية

- كيفية حساب المطاحن والكسارات متطلبات الطاقة

- مطحنة الكرة المورد في المملكة العربية السعودية

- كسارة الفك محطم كسارة المنتج كسارة

- سعر الذهب trommel msi towable

- شاشة لولبية مع مطحنة الكرة

- مشاريع تعدين خام المنغنيز في مصر

- مواصفات الكرات حجم المنتج مطحنة الكرة

- كسارة صغيرة ايطاليا طن

- سعر آلة الكسارة الصغيرة في السعودية

- موردي مصانع الفحم في حيدر اباد

- kerucut harga bijih crusher

- ore deposits that are found in greenschist

- stones quarry and proccessing machines

- ore crushing equipment australia environmnetal impact assessment of li ne quarry

- detail pondasi stone crusher golden star pe x

- recommendation for mining industry html

- skala laboratorium pemasok crusher di india

- crusher equipment production configuration table

- limestone quarrying equipment u s

- crusher coal sampling

- sulfur powder grinding machine

- small scale maize

- portable quartz sand making plants india

- wolfram ore separating equipment wolfram ore mining equipment

- concrete breaking machine from shandong