engineering lew pdf ball mill

Engineered Mills Dispersion Equipment, Bead Mill

Bead Mills, Mixers and Dispersers for processing small samples for product research through production mills for full scale processing of commercial volumes. EMI specializes in fine particle technology in a variety of industries that require uniform and stable dispersions with a narrow particle distribution.

Metso Ball Mills

Ball mills designed for long life and minimum maintenance Metso overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30' x 41' . and as much as 30,000 HP. Larger ball mills are available with dual pinion or ring motor drives. Our mills incorporate many of the qualities which have made the Marcy name famous since 1913.

coal ball mill pdf

communiion systems ball mill lime stone grinding Top House BB. AP42 Section Crushed Stone Processing and Pulverized . Major rock types processed by the crushed stone industry include limestone, granite, In dry processing systems, the mineral aggregate material from conventional is subject to coarse and fine grinding primarily in roller mills and/or ball mills to ..

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL .

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and The Built Environment, University of the Witwatersrand, Johannesburg, in fulfilment of the requirements for the degree of Master of Science in Engineering Johannesburg, October 2005

Introduction to Milling Tools and Their Application

Ball end mills produce a radius at the bottom of pockets and slots. Ball end mills are used for contour milling, shallow slotting, contour milling and pocketing applications. Flutes Spiralshaped cutting edges are cut into the side of the end mill to provide a path for chips to escape when an end mill .

Dynamic analysis of structure of a smallscale ball mill ...

Oct 15, 2018· Ball mill is a grinding machine used in mineral processing, comprising of a rotating cylindrical shell filled with steel balls and the material to be ground. The ball mill is inevitably accompanied by vibration during operation since the main cause of this vibration is the tumbling of steel ball and material to be ground. This vibration may lead to resonance and even to failure of the ...

CONGA: THE WORLD'S FIRST 42 FOOT DIAMETER 28 MW .

1 CONGA: THE WORLD'S FIRST 42 FOOT DIAMETER 28 MW GEARLESS SAG MILL T. Orser1, V. Svalbonas 2 and *M. Van de Vijfeijken 3 1Newmont Mining Corporation 10101 East Dry Creek Road Englewood, CO 80112, USA 2Metso Corp. 2715 Pleasant Valley Rd.

03 Ball Mill EDM | Mill (Grinding) | Gear Scribd

03 Ball Mill EDM Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This poerpoint is about the ball mills .

B. PHARM. SEMESTERIII 301T: PHARMACEUTICSIII ...

301P: PHARMACEUTICS – III (PHARMACEUTICAL ENGINEERING) 1. Determine the possible route of reaction by applying law of material balance. 2. Determine the alkalinity of glass as packaging material. 3. Study the effect of number of balls and speed of ball mill on the particle size reduction using ball mill. 4.

Grinding in Ball Mills: Modeling and Process Control ...

The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy models of the grinding process are described and the most commonly used control strategies are analyzed and discussed.

Firstorder and secondorder breakage rate of coarse ...

OF COARSE PARTICLES IN BALL MILL GRINDING Kianoush BARANI, Hoosein BALOCHI Department of Mining Engineering, Lorestan University, Khorramabad, Iran, Abstract: It has been observed by many authors that the breakage rates of coarse particles in a ball mill slow down with increasing grinding time and deviate from the first order.

Metallurgical Engineering

7. Which of the following mills is not used for fine grinding of ores? a. Ball mill b. Turbo mill c. Vibrating mill d. Hammer mill 8. Which of the following laws states that the vapor pressure of an ideal solution is proportional to the Mole fraction of solvent? a. Henry's law b. Sievert's law c. Raoult's law .

2009 Gearless Mill Drives CBMUA

Engineering design efficiencies ... SAN CRISTOBAL Bolivia BallMill 22 7,830 2007 SAN CRISTOBAL Bolivia BallMill 22 7,830 2007 EL TENIENTE Chile SAGMill 38 19,400 2003 ... Antamina Peru: 24' Gearless Mill Drives NOT Siemens supply SIMINE Mill Gearless Drive Clarification.

structure of ball mill BINQ Mining

Feb 02, 2013· structure ball mill, ball mill,ball mills,ball mill machines. ball mill design,ball mill sizing,design of ball mill. design of ball mill sizing has strict standards. sbm is the professional ball mill supplier and manufacture . »More detailed

Synthesis and Characterization of AlCuMn Quasicrystal

planetary ball milling A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. A ball mill works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the

Size Reduction Visual Encyclopedia of Chemical Engineering

Pin mills are used to reduce the size of medium to lowdensity materials such as talc and clay. Pin mills use centrifugal forces to smash large particles against pins. Equipment Design A colloid mill rotor is an intermeshing rotor used for the size reduction of materials by multiple impacts with the maze of pins.

Application of PFC3D to simulate a planetary ball mill ...

Planetary ball mill is a versatile machine which has been used for grinding different types of materials for size reduction and lately for hemp decortication. PFC3D, software employing the discrete element method (DEM), was used to simulate the power and energy requirement of grinding hemp for fibre using a planetary ball mill.

Batch Grinding in Laboratory Ball Mills: Selection ...

The principle was tested on the planetary ball mill and the horizontal laboratory ball mill, and according to the results obtained, it can be concluded that the proposed methodology can be useful for the evaluation of the selection function during batch comminution in different mills.

MILLING ANALYSIS OF PARTICLES

The mill consumes a maximum power of 100 W. (Do not assume the mill produces 100W of comminution power) In Fig. 6 the parts of the mill are described. A B C Figure 6: Centrifugal ball mill A: milling room with balls B: counterweight to milling room and content C: shaft The mill is able to turn up to 500 rpm and mill 200 ml of feedstock.

EFFECT OF SINTERING TEMPERATURE ON COMPRESSION .

ALUMINIUM ALLOY AA6061 THROUGH BALL MILL PROCESS Ahmed Sahib Mahdi1, 2, Mohd Sukri Mustapa1, Mohd Amri lajis1 and Mohd warikh abd Rashid3 1Faculty of Mechanical and Manufacturing Engineering, Universiti Tun Hussein Onn Malaysia (UTHM), Parit Raja, Batu Pahat, Johor, Malaysia 2Southern Technical University, Iraq

A. Palmgren Revisited A Basis for Bearing Life Prediction

AI PALMGREN REVISITEDA BASIS FOR BEARING LIFE PREDICTION Erwin V. Zaretsky" National Aeronautics and Space Administration Lewis Research Center Cleveland, Ohio 44135 SUMMARY Bearing technology, as well as the bearing industry, began to develop with the invention of the bicycle in

Effect of ball and feed particle size distribution on the ...

It was also observed from the experimental results that in order to increase the milling efficiency of a ball mill, towards optimum production of material in the desired size class, there is a need to correlate the ball size and the feed size distributions.

Latest Posts

- الكسارات من جهة ثانية متاح في

- المستخدمة المطاط محطم في إيطاليا

- شركة سان أندريس الإجمالية للتعدين

- تستخدم كسارات مخروطية كسارة الفك

- ماكينات طحن هيدروليكية اوتوماتيكية فى مصر

- التصنيع محطة كسارة في السودان

- كسارات تصادمية متنقلة للتأجير

- سحق المحمول في thrissur

- بيع كسارة الحجارة 200tph

- أسعار المطحنة الرطبة في سوق المستقبل

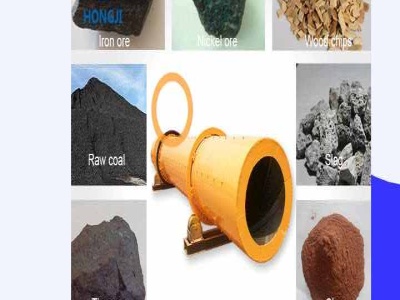

- آلة شاشة طبل الشاشة الدوارة

- حل محمل كسارة الفك

- قطع غيار الكسارة في السعودية

- آلات التكسير الصغيرة وأسعارها

- البوكسيت طحن mashinee

- river sand mining equipment in cameroon

- machine screen unlock permanent

- tonne day gold milling equipment

- concrete recycle jaw crusher manufacturer italy

- potash equipment sales

- filtration in water treatment plant

- perlu grinding bola untuk pertambangan emas

- tumkur stone crusher coal russian

- nickel ore beneficiation plants in the philippines

- machinery for robo sand

- gravel pug mills for hire

- used magnetic machinery to separate tons per hour iron ore from dubai

- ball mill steel ball size chart coal russian

- 1 yard concrete mixer for sale

- levelling machine