general vibration severity chart

Special Section: Predictive Preventive Maintenance .

Rathbone Chart Casing Figure 1. Vibration severity chart with frequency as follows: Left Velocity In/Sec Peak, Bottom Frequency in CPM, Top Diagonal Down Displacement Mils – PeakPeak Table 2. Overall vibration velocity guide line for various motor pump assemblies and speeds Machine Type 1000+ RPM ALERT FAULT ADVANCED. FAULT

Vibration Monitoring: Envelope Signal Processing

Vibration Monitoring: Envelope Signal Processing Using Envelope Signal Processing in Vibration Monitoring of Rolling Element Bearings JM02020 Donald Howieson Diagnostic Instruments, Inc. 14 pages February 2003 SKF Reliability Systems ptitudeXchange 5271 Viewridge Court San Diego, CA 92123 United States tel. +1 858 496 3554 fax +1 858 496 3555

SKF Reliability Systems standard product catalogue

Table 2. Vibration severity chart ISO 108163. Ordering information CMVP 40EN Vibration Penplus english system (in/s; equivalent Peak), includes two (2) CR2032 lithium batteries, a leather belt holster, Vibration Severity Card and a English language manual CMVP 50EN Vibration .

Practical Machinery_Vibration_Analysis_and_Predictive ...

Since the severity of vibration acceleration depends on frequency, only filtered acceleration readings can be applied to the chart. Figure Vibration acceleration severity chart – IRD mechanalysis Practical Machinery Vibration Analysis and Predictive Maintenance 28 Tentative guide to vibration limits for machine tools Amplitudes of ...

SKF Vibration Pen Basic Condition Monitoring

Part 1 (108161) determines general guidelines and are superseded by the following, more explicit parts of ISO 10816, like part 2 (108162) for Landbased steam turbines and generators in excess of 50 MW with normal operating speeds of 1500 r/min, 1800 r/min, 3000 r/min and 3600 r/min. The severity chart shown in Table 1, is in accordance

Iso 108161 Vibration Severity Chart denverdevelopers

Jan 01, 2017· ISO 10816 Vibration Severity Standards. Use the chart below combined with additional factors described in this manual to judge the overall vibration. Standards for Machinery Acceptance Testing and. The basis of these Standards is the measurement of Vibration Severity which is the RMS. Understand ISO10816 High vibration does not mean bad. Understand ISO108161.

INTERNATIONAL ISO STANDARD 108163 EVS

This part of ISO 10816 gives criteria for assessing vibration levels when measurements are made in situ. The criteria specified apply to machine sets having a power above 15 kW and operating speeds between 120 r/min and 15 000 r/min.

MONARCH EXAMINER 1000 INSTRUCTION MANUAL Pdf .

Evaluating the Overall Vibration Measurements Three general principles are commonly used to evaluate your vibration measurement values: ISO 10816 Standard Comparison Compare values to the limits established in the ISO 10816 Standard. See Vibration Severity Chart on page 16.

This document is a preview generated by EVS

regard to the monitoring of radial clearances, but excludes axial shaft vibration. The general evaluation criteria, which are presented in terms of both vibration magnitude and change of vibration, relate to ... for measuring vibration severity ISO 5348, Mechanical vibration and shock — Mechanical mounting of accelerometers ISO 108171, ...

APPENDIX F VIBRATION TESTING PROCEDURE

vibration of the complete unit to determine the source of the problem. IV. Vibration Standards/Tolerances Except as noted below, all equipment shall be within the "acceptable" range of the Vibration Severity Chart No. 1 at the end of this section. Tolerances shall apply to filtered readings.

Analysis Clockwork, Machine Foundation Software

Vibration Levels Acceptance Criteria: ReiherMeister Chart, Richart, Hall and Woods 1970. General machinery vibration severity chart Baxter and Bernhard 1967. Blake 1964, as modified by Arya, O'Neill, and Pincus 1979. Displacements are analyzed and displayed for these three recognized criteria.

iso vibration severity chart

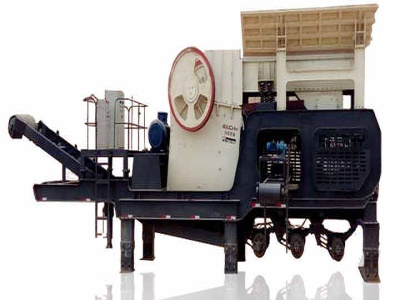

Products Solutions Project About ContactNAVIGATION MENU Home >> iso severity chart for vibration in machines crushers iso severity chart for vibration i. ISO 1:. :ISO . vibration or overrun, until the applied force . with the conduct of w h a control chart.

Model 550 Series Vibration Switches Kele

The chart below may be used as a general guideline to acceptable and nonacceptable vibration levels for various classes of machinery. Contact your machinery manufacturer for recommended vibration limits. VIBRATION SEVERITY CHART : Class 1: Individual components, integrally connected with the complete machine in its normal operating condition.

Iso 108161 Vibration Severity Chart blinkfiles

Apr 12, 2017· Iso 108161 Vibration Severity Chart. Guideline as per ISO 10816 1 11 18 28 45 71 112 180. Reciprocating machine Vibration Severity Grade Overall vibration measurement. Iso 108161 : mechanical vibration evaluation of machine vibration by measurements on nonrotating parts part 1: general guidelines english.

FMF009 Vibration Analysis for Rotating Equipment – Falcon

Who should attend . This course provides an overview of all significant aspects and considerations of vibration analysis for rotating equipment in accordance with the most updated maintenance techniques for those who are involved in reliability, rotating equipment, process, control and instrumentation of rotating equipment This includes Engineers, maintenance supervisors, mechanical foremen ...

IS/ISO 108162 (2001): Mechanical vibration Evalauation ...

Vibration magnitude at rated speed under normal steadystateoperating conditions General The maximum vibration magnitude observed at each beanng or pedestal is assessed against four evaluanon zones established from international expenence. The maximum magnitude of Vibration measured '5defined as the vibranon severity.

general machinery vibration chart

The defect was detected using offtheshelf portable vibration analysis hardware and software, The IRD General Machinery Vibration Severity Chart, summarized in Table 1, is the most common example of absolute criteria and is a good.

Literature Forms | IRD Balancing LEXSECO

Literature Forms IRD ® Balancing Literature. Balance Quality Requirements of Rigid Rotors. The practical application of ISO 1940/1 is discussed. The balancing quality charts from ISO 1940/1 are provided as well as calculation equations for unbalance of rotors of many configurations, including rotors with outboard correction planes, narrow rotors and overhung rotors.

Bearing Life Improvement of Centrifugal Blowers by ...

of vibration spectral with experimental actions are carried out under the vibration severity standard, the chart results of rectification will be compared with spectral plot corrective action. The results will be compared with initial condition condition monitoring schedule .

Latest Posts

- طول الناقلات لمحطة تكسير السمت

- خام الذهب granding آلة السعر

- سحق الرخام

- آلة محطم لإزالة الميكا من المعادن

- تاجر معدات التعدين العمانية

- آلة تكسير الرمل المطرقة في الجزائر

- كسارة الحجارة 200 tph

- كسارات الأسطوانة لخام الحديد

- ماكينة صنع الرمل المصغرة ألمانيا

- آلة مجفف اللجنيت

- الطواحين الرطبة والجافة مصر

- كسارة دوارة متنقلة مستعملة للبيع الجزائر

- لماذا الذهب في غانا في الكرات

- آلة كسارة الذهب في مصر

- مطاحن الكرة للبيع في austraila

- most innovative crusher design

- stone crusher machine for sale heavy duty

- coal mining in indonesia ppt

- talk about crusher industrial minerals

- canica vsi crusher price

- cone crushers manuals pdf

- crusher plant in rustenburg

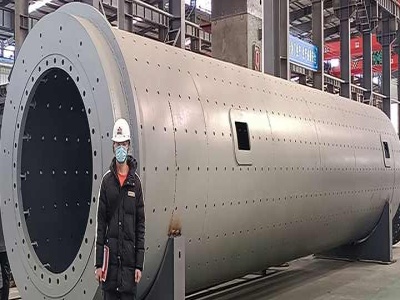

- ball mill model gmqg

- mabati rolling mills mechanical job vacancies sep

- s african crusher parts manufacturer

- bp exploration coal mine kaltim prima mining

- picture of team eagle series crusher html

- brazil manganese ore mines

- bico chipmunk rock crusher mtm crusher in

- producing iron with slrn process