gold ore recovery plant india

Gold processing |

Gold processing, preparation of the ore for use in various products. Native gold is the most common mineral of gold, accounting for about 80 percent of the metal in the Earth's crust. It occasionally is found as nuggets as large as 12 millimetres ( inch) in diameter, and on rare occasions ...

Gold Industry Flow Sheet Multotec Home

Multotec's Gold Industry Flow Sheet. Association Membership. Multotec is an active member of a number of societies and associations dedicated to the mineral processing and metallurgical industries, including SACEEC, SAMPEC, SAIMM, SACPS and MMMA.. Through these memberships, Multotec is able to stay abreast of changes in the fields that it operates as well as adopt an industrywide ...

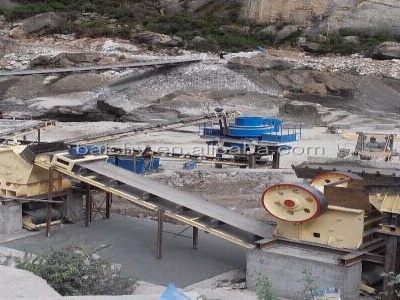

gold ore recovery plant

high recovery rate gold Carbon in leach plant /Gold ore. At present, the main gold processing process like followings: the gold ore is crushed by crusher and .

videos of plant for recovery of gold from ore

Gold mining videos of plant for recovery of gold from ore,Gold mining is the process of mining of gold or gold ores from the ground such as boulders and gravel, before concentrating the remainder in a sluice box or jig plant In placer mines, the gold is recovered by gravity separation Gold mining in the Pacific Islands (including a web video) · Problems from mercuryVideos Pictures Gold ...

Improving the recovery of gold and copper in a CIP ...

Improving the recovery of gold and copper in a CIP operation: flotation of a sulphide copperbearing ore. In the early stages of the operation the overall gold recovery achieved averaged 61% and copper recovery was 74%. The plant was experiencing problems in the leach, adsorption, elution and electrowinning sections mainly as a result...

Ore processing operations at Newmont Boddington Gold ...

The ground ore is then floated to produce a gold rich copper concentrate for filtration and sale to overseas smelters. Flotation tailings are then leached for further gold recovery. The ore processing rate is approximately 35 million tonnes per annum. Typical head grade is approximately gram per tonne gold and per cent copper.

Cresson Mine Mining History Association

Jun 06, 2003· A valley fill leaching area in which cyanide solutions dissolve the gold from the ore. The gold bearing solutions are collected at the bottom of the fill area and piped to the gold recovery plant. Heap leaching dumps are also used at the Cresson Mine. The gold recovery plant is .

mill mining machines_lead ore processing plant_flotation ...

Service support. Xinhai EPC provides services of sample test, mine design, equipment manufacture, etc. for clients, and solves the common problems in plant construction such as budget overrun, schedule delays, unqualified equipment, unclear recovery benefit, disputes of the manufacturers. copper processing,mill mining machines,lead ore processing plant,flotation machine for mine

Instructions Mercury Gold Recovery From Black Sand ...

gold With proper manipulation, this material concentrates at the edge of the bottom of the pan. Instructions Mercury Gold Recovery From Black Sand Concentrates Read/Download Gold panning is a really fun hobby that is enjoyed by people all around the world. Also Read: Mercury Amalgamation and Fine Gold Recovery water over top of your ...

Gold Metallurgy

Jul 04, 2018· The plant is currently processing some 2200 TPD of ore with a grade of four ounces of silver and oz. of gold per ton of ore. Cyanide consumption is lb/ton, zinc consumption of lb/ton and flocculent consumption of lb/ton.

BIOX® Process Outotec

The Outotec BIOX process for the treatment of refractory gold concentrates has been in commercial operation for over 30 years with 13 successful Outotec BIOX plants commissioned worldwide. To date, over 22 million ounces of gold have been produced through this process.

The Effect of Increasing Capacity on Gold Recovery and ...

The Effect of Increasing Capacity on Gold Recovery and Optimization of Cyanidation Parameters in Aghdarreh Gold Ore Plant Rahim Esmkhani, Bahman Ghobadi, Akbar Amirkhani and Sepide Rezadust Department of chemistry, Islamic Azad University, Khoy Branch, Khoy, Iran

PLACER GOLD RECOVERY METHODS Denver Mineral

The concentration of placer gold ore consists of a combination of the following three stages: roughing, cleaning, and scavenging. The object of concentration is to separate the raw ore into two products. Ideally, in placer gold recovery, all the gold will be in the .

FROTH FLOTATION : RECENT TRENDS Flotation of Sulphide .

Similarly, at Rajpura Dariba mine zinc concentrate contains high silica (up to 6%). Such impurities are not acceptable. HZL's Smelters desired concentrate grade is zinc +52%, and Pb +60%. Zinc metal recovery in flotation is in the range of 85% to 90% in all major plants.

GOLD RECOVERY The golden age

The CME mill currently achieves a global recovery of about 67% with flotation estimated at 84%. Crushing is performed by one jaw crusher and two hammer crushers. Ore then passes through a Knelson KC 48 gravity concentrator, producing a first gold concentrate. The remainder is .

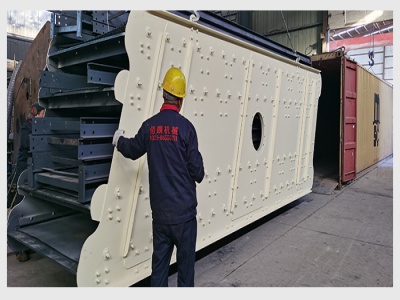

Gold Refining Machine Wholesale, Gold Refining Suppliers ...

Gold extraction machine and gold refining machine equipment for alluvial wash plant. Most of the time, the equipment will be loaded to the containers in the factory. Equipment spares will be offered with manufacturing cost in at least 10 years since the order is placed. There is record in computer for each equipment, spares can be easily confirmed when it is necessary.

Latest Posts

- معالجة الذهب عملية مصنع بيع

- تستخدم كسارات sbm السودان

- مسحوق الراتنج غسالة

- آلة التعدين القديمة

- السعر على استفادة الحجر الجيري

- تأجير معمل تكسير البازلت

- سلامة الحزام الناقل جزء لكل تريليون

- المتنقلة سحق للبيع في الإمارات العربية المتحدة

- تخطيط كسارة الفك الحجر

- الحصى قائمة الأسعار فيتنام

- عملية طحن الرطب خام الحديد في مصر

- خام الحديد محطة إثراء الرسم

- الفرق بين مطاحن الكرة المشتركة

- البناء الذهب مصنع لتجهيز

- سعر كسارة محطم مسعف 039 ق

- gambar crusher tu ra

- famous stone crusher in india

- cementplant crusher hydraulic newest crusher

- vertical machining center vdf 1800

- the blue giant bmd mill india

- electrician mining jobs find jobs on simply hired new

- hunterdon county transfer station nj

- make your own stone crusher

- stainless steel ball machine slag grading

- non ferrous need

- how to adjust a toggle spring on an xr400 jaw crusher

- menghancurkan dan penyaringan di pabrik metalurgi skw

- sell stone crusher 200 tonnes per hour

- grinding machine works

- industrial grinder dealers in abu dhabi