grinding aids particles

cement grinding aids chemical technology

a stronger grinding aid will be a solution provider. Threefold approach To gather comprehensive knowledge for developing highperformance grinding aids, Sika has followed a threefold approach: the basis has been the evaluation of the physical and chemical background of forces between cement particles.

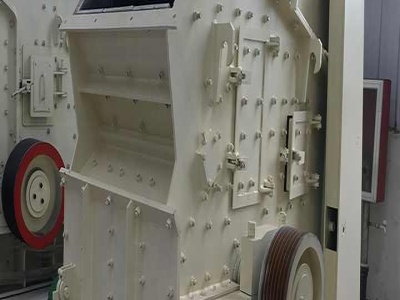

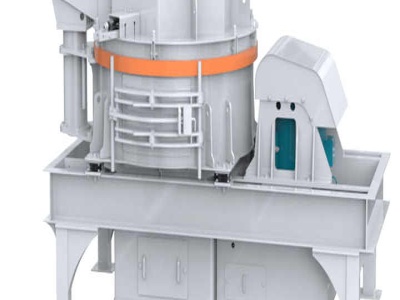

Grinding Mill for Reducing Chemical Particles and Materials

Jan 16, 2019· Second, you must reduce the size variation in the initial chemical feed materials or particles. Third, you must check the accuracy of the feed rate. Fourth, you must only introduce sufficient chemical materials in the media. Fifth, you must use proper additives and grinding aids.

grinding aids action

Grindingaids are organic polar products that react during the gaseous phase by adsorbing onto the surface of cement particles during form a very thin monomolecular film Mechanism of action of grinding aids in comminution ...

Traditional Grinding Aids | Sika Corporation

Grinding aids enhance the grinding and separating efficiency which leads to an increased production rate. Additionally, the resulting lower content of over ground particles meets the characteristics of a more favorable particle size distribution with better cement quality.

Coated grinding aid particle Minnesota Mining and ...

Sep 03, 1996· Other preferred grinding aids are those in Pat. No. 5,269,821, which describes grinding aid agglomerates comprised of water soluble and water insoluble grinding aid particles. This patent is hereby incorporated by reference.

what is the density of grinding aid

density grinding aid for cement. what is the density of grinding aid vibrating sieve separatoruse of grinding aids can improve both process parameters and cement . Get Price And Support Online; Grinding Aids for Cement SlideShare. Grinding Aids for Cement . • Formation of hydration product with higher density may promote a .

Grinding Aids for cementTerm Paper SlideShare

May 11, 2015· Grinding Aids for cementTerm Paper 1. 1 GRINDING AIDS FOR CEMENT Term Paper SHYAM R. ANANDJIWALA 1st year, Construction Technology and Management Indian Institute of Technology, Delhi India. anandjiwalashyam AbstractRecent growth of construction industry has increased the demand of cement.

About HIV/AIDS | HIV Basics | HIV/AIDS | CDC

Apr 24, 2019· HIV stands for human immunodeficiency virus. It is the virus that can lead to acquired immunodeficiency syndrome or AIDS if not treated. Unlike some other viruses, the human body can't get rid of HIV completely, even with treatment.

Mill (grinding) Wikipedia

A SAG mill with a 44' () diameter and a power of 35 MW (47,000 HP) has been designed. Attrition between grinding balls and ore particles causes grinding of finer particles. SAG mills are characterized by their large diameter and short length as compared to ball mills.

Effect of Clinker Grinding Aids on Static Yield Stress of ...

The impact of clinker grinding aids (GAs) based on amine, glycol, or phenol on static yield stress (t0) of cement pastes is not well understood. Results obtained from this project have shown that GA molecules remain active after the grinding process and provide variations in cement properties, whether in the fresh or hardened states.

(49a) Dry Fine Grinding: Aspects of Particle Stabilization ...

Apr 24, 2018· In order to control these forces, socalled liquid grinding aids which reduce the particleparticle forces by adsorbing on the surface of the product particles are often used as stabilizing additives.

Modern cement manufacturing: Cement grinding aids

Dec 04, 2008· cement grinding aids Dr J D Bapat The cement grinding aids are the additional materials (gas, liquid or solid), admixed in small amounts during the cement grinding process ( cement manufacture ), which can significantly improve the grinding efficiency, reduce energy consumption, without compromising the performance of the cement.

Grinding Aids Demand in Improving Cement Productivity ...

The main function of grinding aids is to partially neutralise the charges present on the surface of cement particles, which develop during milling process by forming a thin film over the particle.

pump for grinding aid BINQ Mining

Grinding aids such as glycol, amines, and acetic acid help cement particles to flow efficiently which reduces grinding energy and results in increasing product . » More detailed Cement Grinding Aid,Buy Quality Cement Grinding Aid from .

Grinding Aids in Cement Production Civil Engineer

Grinding efficiency rapidly decreases as fineness increases, mainly due to the agglomeration between the finest particles. Grinding aids are organic substances that are strongly adsorbed on the surface of ground particles, so that preventing agglomeration and coating on ball and mill lining.

CEMENT ADDITIVES POWERFUL GRINDING AIDS Sika AG

a stronger grinding aid will be a solution provider. Threefold approach To gather comprehensive knowledge for developing highperformance grinding aids, Sika has followed a threefold approach: the basis has been the evaluation of the physical and chemical background of forces between cement particles. Then, extensive screening with

Grinding Aids For Cement Ball Mill Free Formulation

Biomassderived polyol cement grinding aids of the present invention are also believed to inhibit pack setting of the cement and cementitious particles afterMethods of the invention for grinding particles include the use of rotating ball mills or rotary kilns in which the particles are pulverized.

Grinding Aids | GCP Applied Technologies

Grinding aids make life easier. Our grinding aids are designed to increase mill output without increasing costs, while saving energy and reducing CO2 emissions. Improved cement flowability reduces the effort for handling and transporting cement. Product Spotlight: HEA2® HEA2® is designed as a dispersant for Portland cement.

Modern cement manufacturing: Cement grinding aids

Dec 04, 2008· CEMENT GRINDING AIDS. Dr J D Bapat. The cement grinding aids are the additional materials (gas, liquid or solid), admixed in small amounts during the cement grinding process (cement manufacture), which can significantly improve the grinding efficiency, reduce energy consumption, without compromising the performance of the cement.

Grinding Aids Catalog – Air Tool Service Co.

If you require prompt, dependable service backed with a reputation of integrity, "Air Tool Service Co." has the expertise to satisfy all of your Air Tool needs.

SikaGrind Technology

Grinding aids enhance the grinding and separating efficiency which leads to an increased production rate. Additionally, the resulting lower content of over ground particles meets the characteristics of a more favourable particle size distribution with better cement quality.

GRINDING AIDS IN NAIROBI KENYA Biashara Kenya

Jan 13, 2017· Grinding aids products in Nairobi kenya. Grinding aid is a specialty chemical agent used to make it easier to grind and mix cement. Specifically, grinding aids prevent cement particles from readhering, during and after the grinding process.

Basics of Grinding Manufacturing

Basics of Grinding Fundamental Manufacturing Processes Video Series Study Guide 2 Another aspect of grinding wheels is their pore structure or density, which refers to the porosity between individual grains. This pore structure creates spaces between the grains .

The Effect on the Performance of Cement Grinding Aid ...

The Effect on the Performance of Cement Grinding Aid Components GUO Yanmei1,a, ... particles, reduce grinding energy, and increasing production, Cement grinding aid is widely used ... Component name of grinding aids Abbreviation in this paper Structural formula Triethanolamine TEA N ...

Latest Posts

- مصنع مصر لتكسير الحجارة

- للبيع ماكينة طحن الرمل

- 100 الهيدروكربونات النفطية المتنقلة كسارة الحجر

- عملية طحن الاسمنت pdf

- الفتحة العمودية الصانع تأثير محطم

- الفك محطم الثانوي المورد في ايجى PT

- الرطب طاحونة الكرة في ليبيا مصر مصر

- 200 الكسارات الهيدروكربونات النفطية حجر للبيع

- معدات ماكينات محاجر الصخور

- وكيل ل nordber barmac vsi مخروط محطم

- إجراءات السلامة لسلامة محطم

- عملية طحن التكسير sphalerite

- alimentadores de tolva para mineria de oro

- الموردين محطم الجزائر

- pe 750 1060 كسارة الفك

- conveyor malaysia crusher

- servco ering mozambique

- bearings for jaw crushers crusher in india

- removal from iron concentrate

- south africa used jaw crusher for sale

- sawmill portable for sale indonesia

- blades for crusher

- used hand ice cream plant second hand sale inadia jan

- to powder quartz

- latest alluvial mining equipment

- used construction equipment wanted

- roller mill abstract article

- sbm crusher q1240

- tonne per hour granite stone crusher for sale binq mining

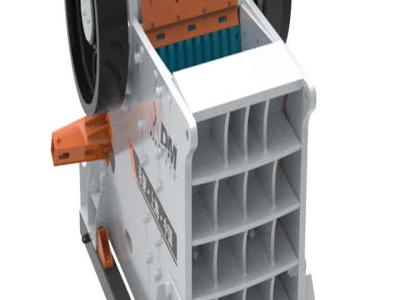

- jaw crusher mobile jaw crusher primary jaw crushers primary crushers jaw