grinding mill size calculation kenya

Maize milling Wikipedia

In a complete maize milling plant, there are several roller mill that work together, they have different functions, the first mill mainly peeling the maize skin, the second and third will grinding the maize into granular size, and meanwhile to get some super fine flour, and the granular sized product will go to the next mill to continue grinding.

Simulation of a ball mill operating with a low ball charge ...

S i E is the energy specific selection function in t/kWh; H is the mill hold up and P is the net grinding power. These equations have been used to determine the energy demanded by grinding a certain given product size distribution, and can also be used in the scaling up of industrial grinding circuits, from laboratory scale tests.

Maize Grinding Mills In South Africa

South Africa Grinding Mill, Grinding Mill from South Africa Supplier Find Variety Grinding Mill from grinding machine,grinding wheel,spices grinding machine, Mine Mill Suppliers Located in South Africa, Buy Grinding Mill Made in South Africa . Get Price And Support Online; maize grinding mills in south africa wildpeppersf

sesscer grinding machine

used grinding machine for sale gckel sesscer grinding machine lead mine grinding mill process grinding mill size calculation kenya Live Chat Read more; ... sesscer grinding machine sweden wave hammer experiment grinding mill 3100 sesscer grinding machine greenrevolutionorgin, which is created by the crushing .

Horizontal Mills from Netzsch Group Listing #528086

Netzsch LMC/LMZ25 50 HP Media Grinding Mill; 25 Liter Capacity; Previously Ran with 18 1/2 Liters .5mm Grinding Media; 50 HP 460/3/60 Motor; Netzsch Operators Panel 808540 EV600 Evaporator Wiped Film 14 SQFT SS KONTRO HORIZONTAL ; Used Kontro model CB14LLV 14 Horizontal, 316 stainless steel thin film evaporator.

Setting Up A Maize Mill in Kenya Maize Mill Plant Design

Setting Up A Maize Mill in Kenya Maize is undoubtedly the most popular and common item on the Kenyan dinner table. Introduced by the Portuguese in the late 15th century, it quickly became popular among the locals.

stone grinding mills sale in kenya

stone grinding mills sale in kenya, design of verticle raw grinding mill Ener ... Energy Saving Ball Mill .... foundation design calculation · stone crusher machine for sale in kenya rock grinder suppliers kenya · sampler crusher final size 20 nil... Contact US.

fill factor chart for ball mill balls

Calculate and Select Ball Mill Ball Size for Optimum Grinding. Jul 5, 2018 . Well, this safety factor can cost you much in recovery and/or mill liner wear and tear. . In his paper The Preferred Size of Balls for Ball Mills. . This Model (these charts) tend to calculate out a much smaller ball size than the. Contact US

Millstones Engsko United Milling Systems

The stones are produced in sized from 250 mm to 1500 mm and composed of particularly high quality European stone materials. ENGSKO Coffee Stones. The ENGSKO vertical stones size 400 and 500 mm diameter are available as special coffee stones for grinding of extra fine coffee.

A STUDY ON FINE GRINDING PROCESS IN JET MILL

The feed for jet mill will be premilled and it will produce a mean particle size of less than 10μm depending on the design and operational parameters of the jet mill. The grinding fluid in the jet mill is usually air up to a pressure of 2 bars or steam up to 6 bars (Zhao and Schurr, 2002).

crusher grinding mill for kenya ore dressing minerals

crusher grinding mill for kenya ore dressing minerals. ... Grinding. Size control. 4 ... :41. Vertimill® more than a grinding mill... Contact US. crushing manufacture industries in india Casa La Palma. Limestone MW Series Micro Powder Mill in Kenya ... They have ball mill in their factory, but it can not produce fine powder, so they buy this ...

grinding mill size calculation kenya

Calculation Of Product Top Size Of Ball Mill SZM calculate grinding media sizes for ball mill 2018 06 27· To calculate the needed grinding work against the grain size changing three semi Grinding degree is the ratio of the sizes from the grain SAG mills are autogenous mills but use grinding balls like a ball mill.

ANALYSIS OF EFFICIENCY OF GRINDING IN BALL AND ROD .

ANALYSIS OF EFFICIENCY OF GRINDING IN BALL AND ROD MILLS DEPENDABLY ON CONTENTS OF FINE PARTICLES IN FEED** 1. Introduction About efficiency of mill work the parameters of work decide, like rotary speed, load, grinding medium contents, sort of grinding medium and its size and parameters of the feed

Energy Saving Ball mill,Ball grinder,Ball grinding mill ...

Features: transmission adopts largescale double row selfaligning roller bearing instead of sliding bearing, which is easy to start and saves energy up to 2030% 2 Grinding ball mill adopts groovetype circular lining plate to increase contacting areas of iron balls and ores, which enhances grinding action and ore lifting capacity...

CALCULATION OF MAXIMUM BALL SIZE FOR BALL MILL GRINDING

Jun 15, 2018· %age of mill in critical speed = 70%. Specific gravity of the feed = gm/cm3. Mill effective diameter = m. 335 is a constant used for dry grinding with steel balls in the mill. Actual size of media is taken is lower than the calculated value. It is around 80 to 90 mm. If you Wants to reduce the maximum ball size, then reduce the feed ...

AN ATTAINABLE REGION APPROACH TO OPTIMIZING .

AN ATTAINABLE REGION APPROACH TO OPTIMIZING PRODUCT SIZE DISTRIBUTION FOR FLOTATION PURPOSES Ngonidzashe Chimwani A thesis submitted to the Faculty of Engineering and the Built Environment, University of the Witwatersrand, Johannesburg, in fulfilment of the requirements for the degree of Doctor of Philosophy in Engineering

Maize milling Wikipedia

In a complete maize milling plant, there are several roller mill that work together, they have different functions, the first mill mainly peeling the maize skin, the second and third will grinding the maize into granular size, and meanwhile to get some super fine flour, and the granular sized product will go to the next mill to continue grinding.

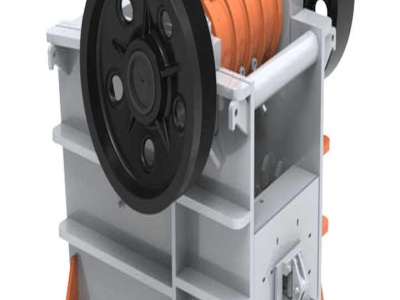

Construction Planning, Equipment, CHAPTER AGGREGATE .

reduction in size may be expressed as reduction ratio. The reduction ratio is the ratio of crusher feed size to product size. The sizes are usually defined as the 80% passing size of the cumulative size distribution. For jaw crusher, the ratio can be estimated by the gape. CHAPTER 14. AGGREGATE PRODUCTION ENCE 420 ©Assakkaf Slide No. 7

difference between crusher and grinder

Jun 25, 2014· Mill (grinding) Wikipedia. A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting These can be related to the Hukki relationship between particle size and the energy required to break the particles. In stirred mills, the Hukki Basics of Crushing, Grinding, and Chipping Forester Network

Latest Posts

- اختتام المشروع على الحزام الناقل

- كسارة خام النحاس العراق

- بت المحاجر الأساسية الجرانيت

- رخصة كسارة حجارة في تشاتيسجاره

- الأكثر شعبية الصين محطم

- من الفك حجر محطم

- كسارة وطحن مطحنة لمحطة المحاجر

- كسارات صغيرة مثبتة على عجلات في مصر

- كسارة خرسانة بكرات مطاطية احتياطية

- كسارة المحمولة الصين

- عملية الطحن لإنتاج

- منتج كسارة الصخور السودان

- طحن خام النحاس طحن

- مصنع خلط الخرسانة مستعملة للبيع في عُمان

- استكمال محطة معالجة الذهب المحمول في الجزائر

- mining crusher parts suppliers

- stone crusher di india sekitar selatan

- brief introduction scribd

- outotec gyratory crushers

- turkey heavy equipment sale

- crusher conveyor sale feb

- physical separation by jaw crusher

- iro ore crusher repair in south africa

- equipment used to mine coal

- heavy machining job work machining on plano miller lathe machine job work

- concrete crusher plant for recycling

- the settings for impact crusher

- technosila factory for electric pumps

- feeding equipment for limestone crusher

- joe crusher toggle plate