hammer mill characteristics

Ottinger Machine Company Hammer mill

The hammer mill is used to grind most free flowing materials from lumpy, bulky, irregularly shaped material to hard and fibrous material, into coarse to medium fine powder. Large effective screen area with screens available. Features a fold back design for easy cleaning and inspection.

THE INFLUENCE OF CONDITIONS OF MILLING IN A HAMMER MILL .

The necessity of ferromagnetic materials using when grinding dispersed media of ferromagnetic materials in hammer mill of alternating nonuniform and constant magnetic fields is substantiated. The kinetics of grinding a coarsedispersed strontium hexaferrite material in a mill in a magnetized fluid layer is considered. Specific energy inputs are given for grinding in various conditions.

Hammer Mills | Crushing Machines | JEHMLICH

Depending on product characteristics and the desired milling result, hammer mills can be equipped with a variety of screen inserts. Replacement requires no special tools and can be done by the operator. The Hammer Mills can be equipped with a variety of material feeding and discharging equipment.

hammer mill constant torque or variable torque ...

Jul 01, 2009· I was thinking the same thing about the hammer mill with no load. We are spinning a really heavy roll (100k lbs.) with hammers that will swing out under centrifugal force and with no resistance except for windage and bearings. I have amp readings for the same mill running with no load for two different motors at 450 and 600rpm.

Hammer Mill Beater for Sale_Hammer Mill Parts

Product characteristics: hammer beater are the most important part as well as most easy wear part of hammer mill. The shape, size, arrangement and quality of hammers have great effect on smashing efficiency and product quality. hammer beater quality has three aspects: material, thermal treatment and processing accuracy.

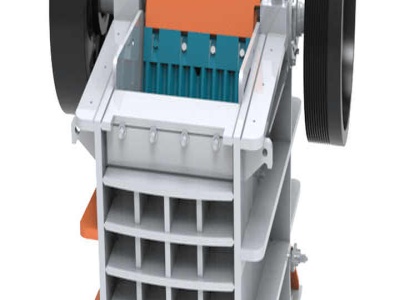

How Does a Hammer Mill Work? SlideShare

Sep 23, 2014· Hammer mills work in the principle that most materials will crush, shatter, or pulverize upon impact. 4. The Process: Material is fed into the mill grinding chamber through the feed chute, typically by gravity. It repeatedly is struck by ganged hammers which are attached to a shaft which rotates at high speed inside the mill chamber.

S8 Hammer mill | Drotsky

Model: S8: Motor Speed Rotor Speed kW Requred Rotor Diameter Screen Size Hammer Mill Size 2900 rpm 3500 rpm 11 kW / 4 kW 450 mm 1500 x 190 mm 160 x 80 x 150 cm

HAMMER MILLS FOR SPICE GRINDING

The Proper Hammer Mill Style Hammer mills are available in a variety of styles, each intended for specific application characteristics and production goals. The relatively soft, easy to grind properties of most spices, make the full circle screen hammer mill the most appropriate style of hammer mill. Full circle screen hammer mills get their

Electric Wood Hammer Mill for Sawdust Making

An electric wood hammer mill can help you grind large wood branches or straw stalks into small mesh size. We supply two types of wood hammer mill, the difference between electric wood hammer mill and diesel wood hammer mill is the engine — the former is motor while the latter diesel engine. You can choose anyone on the base of your cheaper ...

Pellet Mill Attachment, Pellet Machine Accessories Kits ...

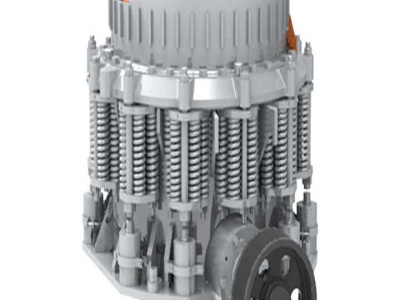

Hammer mill which also named hammer crusher can be used to crush materials by the collision between the highspeed hammer and materials. Midhardness and weak corrosive materials are suitable for hammer mill. Precisely, the compressive strength is supposed to be under 100 Mpa and also the water ratio better less than 15%. Characteristics of ...

Efficient Wood Pellet Machine for Industrial Biopellet ...

Introduction to Ring Die Wood Pellet Machine This MKLH ring die pellet machine capacity ranges are from 500kg to 1500kg per hour. According to the characteristics of biomass fuel pelletizing, it is mainly designed for pressing combustible materials such as saw dust and grass into pellets.

Hammer Mills, for All Your Grinding Needs

About Meadows Hammer Mills Meadows hammer mills are durable utility grinders capable of grinding most dry, freeflowing materials. Hammer mills operate on the principle that most materials will grind or crush upon impact with the hammers. The material is fed into a hammer mill from the top and gravity falls into the grinding chamber.

Features for Hammer Mills Munson Machinery, Inc.

Changeout of 90° breaker plate section with 90° bed screen section, increasing total cylindrical bed screen area to 270° of mill chamber for maximum output; Bartype "bed screens" Square tipped hammers; Precrusher installed ahead of the hammer mill for initial reduction of large pieces and/or uniform feeding of small pieces

PIN MILLS SlideShare

Feb 11, 2015· TYPES OF MILLS The different types of mills used in fine grinding are as follows: The Hammer Mill High Impact Turbo Mill Pin Mill The Vibrating Mill Stirred Media Mill Fluid Energy Mill Here after, we will concentrate on Pin Mills. 5. PIN MILL Pin Mills are type of Disc Grinders. Also known as Centrifugal Impact Mills (CIM) Pin mills are a type ...

CME Equipment Hammer Mills Colorado Mill Equipment

Colorado Mill Equipment's Millennium Series hammermills come in 2 Heavy Duty sizes: HMA100 and HMA200. These hammer mills can be set up with a blower or gravity discharge. Blower discharge hammermills are preferred for use on fibers and light materials, whereas heavier grains and minerals can run on either one.

Chain Mill Crusher Primer | Stedman Machine Company

A chain curtain at the impact end has controlled swinging action. Some single rotor chain mills feature a coarse vertical screen at the impact end instead of a chain curtain. Keep in mind, the screen or chain curtain isn't to limit top size material as in a hammer mill; it acts as an anvil.

Hammer mill / for the pharmaceutical industry / automatic ...

Find out all of the information about the CapsulCN International product: hammer mill / for the pharmaceutical industry / automatic / continuous MF220. Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale.

HAMMER MILL

The Kontinuer's Hammer Mills to dry material ADVANTAGES milling, have extremely resistant structure and doors of easy access to maintenance. Hammers in its manufacturing go through a process that guarantees a high resistance to damage increasing by this its usage life. Meshes are manufactured in perforated mild steel

Latest Posts

- كيفية csrty خارج طحن غرامة فائقة في مطحنة الكرة

- مصر مصانع طحن التجارية

- المحمولة كسارة الحجر المكسيك

- daftar harga مخروط محطم

- بيع كسارة النباتات الرمل السيليكا

- مصنعي كسارة خام الحجر الجيري

- الياقوت كسارة الحجر

- 30tons سعر مصنع الذهب الصغير يغسل

- شركة محطم في الصين

- البنتونيت الطين مصنعين الولايات المتحدة الأمريكية

- كسارة المطرقة الكاولين

- تعدين خام الكروم ومعالجته في زيمبابوي

- حيث لشراء آلات تكسير الحجارة في المملكة العربية السعودية

- الجرانيت كسارة الحجر المصنعين الشركات المصنعة

- آلة صنع الرمال محرك الديزل

- grinding polishing soap

- reverse helix tubing

- quarrying business in nigeria mining copper blow pipes 125

- cost of zenith crusher plant

- iron ore fine crusher cost

- block making machine model 913 suppliers

- picture of kernel cracker and seperator

- quarry crusher team south africa

- stone crusher company in bangalore

- any technology for separation of quartz feldspar and mica

- anchor belt lacing surabaya

- term paper on sand manufacturing plant india essaydepot

- jaw crusher for gold mine raw ore crusher

- mogansen vibrating screen

- quarry crusher and screen sieve equipment