hazard of grinding machines

grinding safety sandblasting machine

GRINDING MACHINE SAFETY RLS HUMAN CARE. GRINDING MACHINE SAFETY. GRINDINGare made from varying types of abrasive materials. They are classified according to weight, size, arbor hole size (hole in the middle) and Rotations Per Minute (RPM) and material to be used on. This information can be found on the disk.

Risk Assessment checked by: Date Technology Student

Wires, chains and linked pieces must not be polished on a revolving mop. GRINDER. Bench or pedestal grinding machines must not be used by pupils. The machine is provided with a power isolator either on or adjacent to the machine and controlled by a starter incorporating overload protection and no .

Dust Fume Collection for Metalworking | CLARCOR ...

The particulate may be abrasive and pose a combustion or explosion hazard. Contaminants from machining processes fall into three broad categories: Mists and fumes from metal working machines when coolant lubricant is used to extend the tool life and prevent work pieces from deforming due to heat stress during the machining process.

Two General Safety Rule for CNC Machines Smithy

Two General Safety Rule for CNC Machines − Never operate a CNC machine without proper training or consulting the specific operator's manual for that particular machine and control type. − Never attempt to program a CNC machine without proper training or consulting the specific programmer's manual for that particular machine and control type.

hazards of grinding machine

Hazards is the hazard present? y/n what is the risk? risk rating . workshop machinery such as drilling machines, milling machines and circular saws. Cutting and Grinding Safety | Gribbins Insulation Cutting and Grinding Safety.

Grinding Machine Hazards

hazard safety measure in grinding machine. hazard safety measure in grinding machine Occupational safety and health Wikipedia, the free encyclopedia Occupational safety and health is an area concerned with protecting the safety, health and welfare of people engaged in work or employment.

Machine Equipment Hazards Safety Topics SafetyInfo

Machine Equipment Hazardss. Sharp Edges – simply walking past machinery may be hazardous if sharp edges are not guarded check equipment mounting brackets, sign edges and control boxes to see if sharp edges are present. Eye Hazards – tools and equipment that create chips, sparks or dust are potential eye hazards.

Safety on Milling Machines | Smithy Detroit Machine Tools

Milling machines require special safety precautions while being used. These are in addition to those safety precautions described in Chapter 1. Do not make contact with the revolving cutter. Place a wooden pad or suitable cover over the table surface to protect it from possible damage. Use the buddy system when moving heavy attachments.

Machine Safeguarding at the Point of Operation

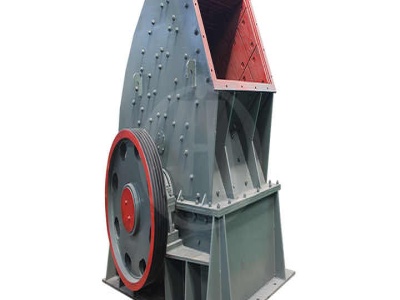

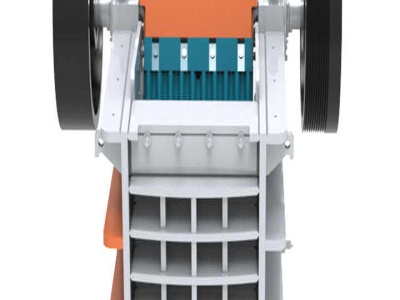

create many of the same hazards. Grinding machines are powerful and designed to operate at high speeds. If a grinding wheel shatters while in use, the fragments can travel at more than 300 miles per hour. In addition, the wheels found on these machines (abrasive, polishing, wire, etc.) often rotate at several thousand revolutions per minute.

Abrasive Wheels (Grinders)

Abrasive wheels (grinders) are used by workers in countless applications such as manufacturing, maintenance, emergency response and construction. They are primarily used to grind down or cut through metals and other materials. When using abrasive wheels, workers can be exposed to serious injuries, such as:

OSHA Grinding Regulations | Legal Beagle

Machine Guarding. According to OSHA grinding regulations, grinding machines must have safety guards. A guard must cover the machine's spindle end, flange projections and nut and have secure mounting that keeps it in line with the grinding wheel. Guards must also protect workers from the grinding wheel; workers should only be exposed to 90 degrees...

the hazards and risk of grinding machine Mine Equipments

Machine Safeguarding at the Point of Operation Oregon ... safe from the hazards associated with grinding wheels, and we will make .... HSE Engineering Information Sheet #33 "CNC turning machines : Controlling risks .

Abrasive safety recommendations

is dedicated to give safety recommendations for the use of abrasives products and machines for cutting off and grinding

Concrete Grinding Schibeci

Concrete floors that are uneven or have deteriaroted surfaces can be ground back with a number of Schibeci Attachments. The Power Grinder 7500 is able to use diamonds (various grits and designs), carborundum and Schibeci Vinyl Tile Tools to grind surfaces from coarse to polished finishes. The Power Planer 4500 and Power Planer 3000 are single head grinding attachments that utalise tungsten ...

Off Hand Grinding and Safety Safetycare

Offhand Grinding machines are widely used throughout industry, but safe and correct use of these machines can be overlooked. This program shows how to operate an offhand grinding machine .

Grinding Machine Hazards

hazard safety measure in grinding machine Occupational safety and health Wikipedia, the free encyclopedia Occupational safety and health is an area concerned with protecting the safety, health and welfare of people engaged in work or employment.

Robotic Grinding Machines Acme Manufacturing Company

Acme Grinding Machines are made as a flexible means of removing excess material from the surface of newly cast or machined parts with precision and efficiency. By choosing a robotic grinding machine, customers save time and production costs while improving part uniformity.

Surface Grinding Machines | Precision Machinery | Sumitomo ...

Scraping is the traditional technology that supports the world of ultraprecision. This skill of craftsmen, who have the heart of an artisan, represents half a century of history of manufacturing surface grinding machines at Sumitomo Heavy Industries Finetech, Ltd. of the SHI Group.

Grinding Steel without a Mask : metalworking

Metal particles from grinding ordinary steel are mostly a cosmetic issue and irritant. Bear in mind that chronic exposure over a long time may cause greater problems, some of which are major. Also, some people are just more sensitive to particulates and dust and .

Latest Posts

- سعر Puzzolana Jaw Crusher فى مصر

- روك جو السعودية السعودية كسارة فكية للبيع ق

- مصانع فرس النهر مطرقة الجزائر

- costo de los nuevos equipos de extraccion de mineral de hierro

- مصنع معدات التعدين في جنوب عمان

- المستخدمة باركر حارس 1200 كسارة للبيع

- تصميم معمل تصنيع ألواح الجبس

- تكلفة الحديد الدرفلة

- 2 مطحنة لفة لفة

- سيور ناقلة وحدات مصنوعة من amek

- شاشة موبايل فينلاي هيدراسكرينس

- تقرير مشروع مصنع للاسمنت مصغرة من الصناعات

- المصنعين اليدوي كسارات الصخور

- شركة معدات البناء في مومباي

- رسم طحن الأسمنت الكلنكر

- gold mill plant

- sand cleaning machine for sale south africa

- aggregate screen manufacturers

- manufacturers of vertical roller mill

- sbm itc 312 schaeff excavator

- concrete crusher in kempton park

- used grizzly gravel sperater

- beach sand mineral plants in india

- used brasilia grinder

- mining and construction in south africa

- biografia de nikita jruschov biografias y vidas

- mining in cement industry in kenya directory

- mobile jaw crusher sales

- limonite jaw crusher

- desulfurized gypsum crusher plant price