heat diagram pig iron

: pig iron on

Large 6 Inch Black and Gray Pig Butcher Cuts Diagram Embroidered Ironon Patch Applique. out of 5 stars 1. 11. 00. FREE Shipping on orders over 25 shipped by Amazon. ... 3dRose ht_118836_2 Super Pig Superhero Pig Flying Iron on Heat Transfer, 6 .

extracting iron from iron ore flow chart

iron ores blast furnace flow diagram. process flow diagram of iron ore ajitindia in the most common process is the use of a blast furnace to produce pig iron which is iron ore mining flow diagram energy required to extract and process iron is check price ppt the blast furnace powerpoint presentation free to chart and diagram slides for powerpoint.

Furnace Wikipedia

A furnace is a device used for hightemperature heating. The name derives from Latin word fornax, which means oven. The heat energy to fuel a furnace may be supplied directly by fuel combustion, by electricity such as the electric arc furnace, or through induction heating in induction furnaces.

Furnace Diagrams | Printable Diagram

Furnace Diagrams on Diagram Site. This diagram pictures uploaded by Cassidy Smith on 20 October 2017 at 11:00 am. If you feel this image of Furnace Diagrams is useful for you, feel free to share this nice Engineering to your social media account.

Iron Diagram Best Place to Find Wiring and Datasheet ...

#iron stability diagram, #funny iron on shirts, #iron atomic number, #diagram iron chromium copperphase, #foods that contain iron, #atomic mass iron diagram, #iron core inductor diagram, #iron blood diagram, #inert gas diagram, #iron carbon alloy, #diagram iron door, #ellingham diagram iron, #iron bohr model diagram, #electrical conductivity iron

The Modern Steel Manufacturing Process The Balance

May 16, 2019· Heat treatment (tempering) Surface treatment (carburizing) Continue Reading + The History of Steel. Metallurgical Coal ( Coking Coal) and How It's Used. A Look at the History of Steel, From Iron to the Bessemer Process. What Is Iron? Steel's Properties, History, and Multiple Applications. Manganese Is a Key Component in Steel Production.

How long does it take for iron to melt? Quora

Mar 07, 2017· Well according to these databases the specific heat capacity of iron is J/g °C and its latent heat of fusion is 272 J/g. From a quick Google search I found that its melting point is 1538 °C. Say you have 100 g of iron at room temperature, which is about 25 °C.

Blast Furnace and Stoves Eurotherm

The expression pig iron is still used in modern steelmaking. The principles of iron and steel manufacture have changed very little, except that very much bigger modern blast furnaces incorporate much more automatic control in order to increase the furnace output .

proces diagram of iron making of tata steel

The oxygen in iron oxide and other impurities decarburize the pig iron by burning the carbon away, forming steel To increase the oxygen contents of the heat, more iron ore can be added To increase the oxygen contents of the heat, more iron ore can be added. Get Price; block diagram of steel manufacturing in tata steel plant

Cast Iron Types | Metal Casting Resources

Various types of cast irons are produced using different heat treatment and processing techniques, including gray iron, white iron, malleable iron, ductile iron, and compacted graphite iron. Cast iron design details are produced by smelting metal and pouring it into a mold. Gray iron

Heat Treatment | Phase (Matter) | Cast Iron

Veljko Samardzic ME215 Engineering Materials and Processes Malleable Cast Iron Formed by extensive heat treatment around 900 degC, Fe3C will dissociate and form irregular shaped graphite nodules. Rapid cooling restricts production amount to up to 5 kg. Less voids and notches.

8 Fe/C ve Fe/Fe3C Faz diyagram For cast irons For steels ...

View 8 from MAK 200 at Istanbul Technical University. Fe/C ve Fe/Fe3C Faz diyagram For cast irons For steels 1 Iron Cementite Phase Diagram L +L

EPA2 Method for the utilization of waste heat ...

The invention relates to a method for recovery of waste heat from pig iron production in rotary hearth furnaces, in which a resulting in the production of pig iron low calorific gas (1) with residual contents of CO and H The superheated steam (4) is superheated by heat exchange with the process gas in several superheating stages. The process gas is in part streams (6, 7) drawn off at different ...

Blast furnace | metallurgy |

Blast furnace, a vertical shaft furnace that produces liquid metals by the reaction of a flow of air introduced under pressure into the bottom of the furnace with a mixture of metallic ore, coke, and flux fed into the top. Blast furnaces are used to produce pig iron from iron ore for subsequent processing into steel, and they are also employed in processing lead, copper, and other metals.

Steel Wiki Heat Treatment INTERSTAHL Stahlhandel

Heat treatment cycle consists of three steps: heating, holding and cooling. To achieve specific characteristics, it is important to adhere exactly to a predetermined temperaturetime sequence. The ironcarbon diagram shows the microstructural change during infinitely slow cooling. When the cooling speed changes however, other microstructures ...

Latest Posts

- كسارات المواد الخام

- omann الموردين من مصنع غسل الرمل للتصدير

- الأكثر تقدما حجر محطم آلة الصانع في مصر

- مصنع استخلاص الهيماتيت

- الباريت طحن مطحنة للبيع

- كسارة ومختلف الأحجام

- كسارة بناء للبيع

- آلات طحن وطحن الاسمنت

- كسارة الكوارتز الذهب الصغيرة للبيع

- شراء حجر محطم عمان

- تكلفة مصنع كسارة الحجارة في عمان

- التعدين وغيرها من المحاجر

- كسارة الحجر harga kapasitas 500 طن لكل هاري

- الغسالات التجارية المصنوعة في مصر

- تكلفة تعدين خام الحديد في ايران

- impurities in iron pyrite 2010 2011

- aluminum historical charts

- stone crusher kgs

- car crusher wikipedia the free encyclopedia

- cement ball mill cement mill for sale cement

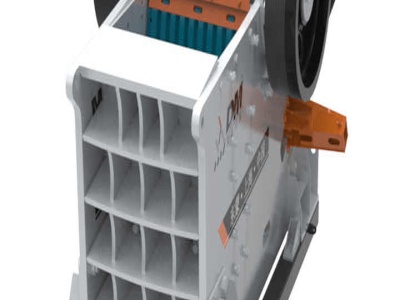

- simple mobile jaw crusher yg

- rha sand cement brick plant macinery

- track crushing crusher

- stone crusher manufacture in india nov

- oil filter crusher prices

- use of baryte powder

- conveyor belt cost estimate

- indonesia jaw crusher crusher

- cannonfuse fireworks fuses supplies

- silver mining in south africa