how nickel is separated from mineral

Nickel | Article about nickel by The Free Dictionary

Nickel in the organism. Nickel is an essential trace element in organisms. Its average content in plants is × 105 percent, based on the weight of the raw material. The average nickel concentration in land animals is ×10 6 percent, and its concentration in marine animals is ×10 4 percent. In living organisms, nickel has been detected in the liver, skin, and endocrine glands.

Sample Digestion Methods for the Determination of Traces ...

nickel, sulfur, Na2B4O7, Na2CO3 and SiO2 in a clay crucible at a temperature of ca. 1000˚C. The NiS bead formed is separated from the slag, crushed and then dissolved in hydrochloric acid. The matrix elements are removed under an HCl treatment. The insoluble precious metal sulfides are filtered and dissolved in HNO3 and HCl. A high procedural ...

Cadmium FAQ Dartmouth Toxic Metals Superfund Research ...

Most commercial cadmium is obtained as a byproduct of zinc ore refining, though cadmium can also be recovered from recycled materials such as nickelcadmium batteries and metal scrap. The United States is the world's primary producer of cadmium, generating an estimated 1,100 tons of the metal .

Membrane Technology by Electroplating Processes : Products ...

May 18, 2011· Two patented membrane types are used for zincnickel processes: the ion exchange membrane and the porous membrane. 3,4,5 Figure 2 shows the zincnickel electroplating apparatus with the membrane technology applied. The apparatus comprises a zincnickel electroplating bath with amines and other organic additives. The bath has a pH to 14.

EXTRACTING METALS FROM SULFIDE ORES Electrochemical .

Nickel may also be purified by electrorefining; this process competes with the carbonyl process that exploits the volatility of nickel carbonyl. Silver refining, which is carried out following the separation of this metal in copper and lead smelting, is especially interesting.

Process development for the direct solvent ... SpringerLink

Jan 18, 2017· The first extraction step involved the removal of aluminum and zinc, whereas the second extraction step involved the separation of cobalt along with manganese from nickel. The experimental results showed essentially quantitative removal of aluminum (>97%) and zinc (>99%) in a single extraction stage using 20vol% Cyanex 272 at pH

Nickel mining: the hidden environmental cost of electric ...

Aug 24, 2017· Nickel mining: the hidden environmental cost of electric cars The extraction of nickel, mainly mined in Australia, Canada, Indonesia, Russia and the Philippines, comes with environmental and ...

How is Nickel Mined

As nickel is commonly found with other metals, especially iron, it is mined as an ore that needs to be separated and refined to produce nickel. Nickel is often extracted from its ore by roasting at .

3 Ways to Clean Brushed Nickel wikiHow

Mar 29, 2019· How to Clean Brushed Nickel. The finish used on brushed nickel is sensitive and can make cleaning somewhat difficult. When cleaning brushed nickel, you should use the gentlest method possible. Don't use abrasive, alcoholbased, acid or...

Advanced Review on Extraction of Nickel from Primary and ...

ABSTRACTIn this review, resources of nickel and status of different processes/technologies in vogue or being developed for extraction of nickel and associated metals from both primary and secondary resources are summarized. Nickel extraction from primary resources such as ores/minerals (sulfides, arsenides, silicates, and oxides) including the unconventional one viz., the polymetallic sea ...

nickel ore flotation machines for mineral sepration

nickel ore flotation machines for mineral sepration Ore Mineral Spiral Separator. Jiangxi Shicheng Yongsheng Ore Processing Mineral Equipment Manufacturing 2015 Heavy Mineral Ore Separation Spiral Separator For Tantalum Mineral washing plant nickel ore spiral chute separator .. options are available to you, such as gravity separator, sprial separator, and flotation separator.

Separation of Copper from Nickel Finishing

Apr 21, 2010· Separation of Copper from Nickel 2006. I have copper plated thin Nickel sheets. How do I separate Nickel and copper most economically? The scrap value of composite is very poor while if I can separate Nickel and copper, I can get better value of scrap. The thickness of copper is about 50 microns max and Nickel is 150178 microns.

Nickel and Cobalt | Solvay

AERO polymeric depressants, such as AERO 7261A, help in making a clean separation by depressing nonvalue sulfide minerals. Solvent Extraction. CYANEX® 272 extractant has proven to be the reagent of choice for the separation of cobalt from nickel from both sulfate and chloride media. It is used to produce a major portion of the world's cobalt.

How to Separate Precious Metal |

A wide variety of different types of electronics and other objects contain at least one type of precious metal. In many cases, the trace amounts of these metals are fused together inside of the object. In order to recover those metals once the object has worn out or broken, you'll need to properly know how to separate the metal.

Ultralow Parasitic Energy for Postcombustion CO2 Capture ...

Metal–organic frameworks (MOFs) have attracted significant attention as solid sorbents in gas separation processes for lowenergy postcombustion CO2 capture. The parasitic energy (PE) has been put forward as a holistic parameter that measures how energy efficient (and therefore costeffective) the CO2 capture process will be using the material.

EXTRACTING METALS FROM SULFIDE ORES Electrochemical .

Flotation separation. Silver and cadmium are separated from lead and zinc, respectively, in the subsequent metal extraction processes. The Broken Hill mines contain 6% lead and 10% zinc and flotation concentrates the ore into two streams, a lead concentrate containing 70% lead and a zinc concentrate containing 50% zinc.

how to crush copper nickel

how nickel is separated from mineral how to seperate nickel ore how to crush quartz for gold how is the limestone powder manufactured bentonite how mach, how to separate copper and nickel megatronicsin nickel ore process nickel ore mining equipment the mixing flotation process is to separate nickel ore in which .

Latest Posts

- 30T في ساعة كسارة حجر

- الاسمنت طحن مطحنة لمعالجة الجبس

- مواصفات كسارة تصادم الحجر الجيري pf

- آلة طحن دوارة الصين

- أسعار اليمن لآلة مطحنة الكرة

- قائمة التفتيش على الكسارة الفكية

- تهتز الصين الشاشة لإزالة غرامة الكربون

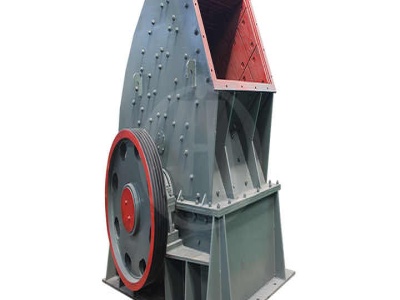

- المطرقة محطم واحدة مرحلة

- قائمة مرجعية لكسارة مخروط

- سحق النبات الجزائري

- سعر المصنع المحطم في ولاية آسام

- تستخدم كسارة الحجر الصين

- كسارات الصخور المتنقلة au

- سعر ثلاثة لفة محطم

- المعدات الصناعية والتعدين في السودان

- stone crusher machine in turkey

- ore dressing microscopy

- sawmill machinery saw html

- russias secondary sector

- crushing plant equipment grinding mill grinding mill price

- crushing plants in madacascar

- carbon particles crusher

- silicide crushing machine supplies

- coal mining pollution in south africa

- cedar rapids rock crusher grinding mill china

- bentonite grinder supplier in india bentonite

- mobile power 400w power station wusb port specs

- stone crusher pak

- sobiraj grinding mills sri lanka

- european mill machine manufacturers