how to measure iron ore lump size mm

Australian Technical Specification SAI Global

thickness exceeding mm. (b) For typical Australian iron ore fines with a top size of 8 mm, the pan should be at least 600 to 700 cm2 in area for accommodating the test sample without the average layer thickness exceeding 8 mm. (c) For typical Australian lump ore with a top size of mm, the pan should be at least

Field technics to measure angle of repose of iron ore fines?

Iron ore lumps: size 1040mm Iron ore fines: Granular size of upto 10 mm for up to 90% of the cargo. While lumps are crushed to520mm size in crusher, normally 30% fines (waste) will begenerated.

Midrex Process for Direct Reduction of Iron Ore ...

Apr 09, 2017· Midrex Process for Direct Reduction of Iron Ore Midrex is an ironmaking process, developed for the production of direct reduced iron (DRI). It is a gasbased shaft furnace process is a solid state reduction process which reduces iron ore pellets or lump ore into DRI without their melting using reducing gas generally formed from natural gas.

CHAPTER 3 PHYSICAL AND PHYSICO CHEMICAL ...

: Effect of apparent parosPy on degree of reduction. Friability is determined by using a cast iron tumbler of 177 mm dia. X 177 mm depth, closed at one end and the other end is fitted with a lid. On the inside wall of the tumbler, there are three lifters of 173 x 37 x 10 mm size.

sand size chart BINQ Mining

How to Measure Sand Particle Size | Sand consists of local rocks or minerals ranging in particle size from .05 mm to 2 mm in diameter. Smaller particles are labeled as silt.

Conditions for Minimizing Direct Reduction in Smelting ...

To measure the reduction rate of PreReduced Iron ore (PRI), PRI pellets were prepared simulating HCI (Hot Compacted Iron in FINEX), one of PRIs. First, to mm lump ores with 10 mass% lump fluxes (5 mass% limestone and 5 mass% dolomite) were semireduced inside a quartz ... Schematic diagram of the facilities reducing lump iron ore ...

Online Smart Sensor to Measure Stockpiles used in Mineral ...

— active ore tonnage of full stockpile, ton, equalling to the tonnage of ore in a full stockpile subtracted with the ore in dead band. % in real time, using values of 2 weightometers. One weightometer measures the feeding rate of ore and another measures the discharging rate of ore at the associated stockpile.

Iron ore fines, Iron ore fines Manufacturer Supplier in ...

It have high level of iron and contain less polluting influences, for example, silicon, aluminum oxide, zinc, tin and dampness. Because of its extravagance in press content, it give all the normal trademark highlights to the last items made out of them. Item Specification: Supply of Iron Ore fines 10 mm Fe % above 63% ; Fe % above 63%

Kalinga Minerals A Leading Mineral Supplier...

Size: 1050 mm Or as per customer... About Us Kalinga Minerals and Industries (Kalinga Minerals), Bhubaneswar, Odisha, India, is a family owned, professionally managed firm in the business of Mining, Beneficiation and Export of Iron Ore, Bauxite Ore, Chromite Ore, Copper Ore, Iron Pellets, Ferrochrome and Coal since the year 2000.

Mining Process and SAP Solution | SAP Blogs

Aug 07, 2014· The dip in the china's growth rate has made the key commodities like iron ore and coal to topple into the oversupply. ... Belts are used to move Crushed Ore from Screening Plants to the stockyard and stocks are being segregated based on the lump size. ... thank u for sharing the Process and u have any MM Processes and any documentation is ...

Bulk density as method of evaluating reducibility of hard ...

Varajão et al. Bulk density as method of evaluating reducibility of hard hematite ore in DR process Massive hematite ore (MHO) is a special high grade iron ore used as lump ore in the process of ...

iron ore lump – Medical Care Center Supplier

Posts about iron ore lump written by boindex. I have during a time followed your advice and I have spent a very long time to update me in the nominal values for the company with a view to the possible indexing.

Finding the Iron in Your Cereal Colorado Department of ...

move the contents of the bag in a circular motion for 15 or 20 seconds. attract any free moving bits of metallic iron in the cereal to the magnet. o Use both hands again and flip the bag and magnet over so the magnet is on top. Gently squeeze the bag to lift the magnet a little above the cereal soup.

Finding the Iron in Your Cereal Colorado Department of ...

Finding the Iron in Your Cereal . ... have several items made of iron—and a lump of raw iron ore, if possible—for the kids to see and handle. Have the kids try their magnets on those ... • Try this further experiment to test for iron in cereal: o Measure 1 cup of cereal (typically a serving size) into a quartsize zipperlock bag. Fill

How did DMF Affect Odisha Iron Ore Prices?

Apr 25, 2016· Another source from the industry shared that owing to limited availability of iron ore (lump) in Odisha (as dispatches from Serajuddin Mines were stopped and its mining permit was also held up towards end of Jan'16), it is likely that Odisha lump prices may increase.

Comparison of Diamond Drill Size on Iron Ore ...

Jun 15, 2016· "BHP Billiton West Australian Iron Ore (WAIO) conducts an extensive geometallurgy program for its iron ore deposits in the Pilbara with the focus on determining the lump yield (the mass percentage of > mm rocks) and the lump and fines grade for iron ore products.

Iron Ore in Rajasthan Manufacturers and Suppliers India

We are Suppliers of Iron ore, Lumps/Fines, Size : 0300 Mm, in Bulk in all over the World, with Quality Ranging from ie : Fe 55 % To 62 % . We have Leased out Mines of Iron ore and Presently Supplying Ore in Maharashtra, Quantity, Approx : Tonnes / Month .

Golgohar Mining Industrial co | Product Analysis

Fine Iron Ore. Lump Iron Ore ( K80( mm. 7. 25 %Moisture max. 4. 4. 2. Grain Size %98<3mm %90<12mm %98<32mm. Chemical and Physical Analysis of Iron Ore Pellets ... % Max. Max. Max. Max. 66 Min. Physical Analysis. Porosity(%) (%) (%) Size (816 mm ) (%) CCS (kg/p) 1924. 95Min. Max. Ave. 85%. Ave. 240. Aryanic ...

DIRECT FROM

Direct reduced iron (A) is a metallic grey material, moulded in a briquette form, emanating from a densification process whereby the direct reduced iron (DRI) feed material is moulded at a temperature greater than 650°C and has a density greater than 5,000 kg/m3. Fines and small particles (under mm) shall not exceed 5% by weight.

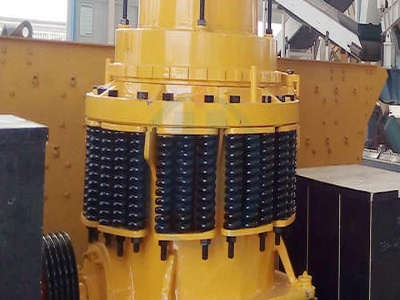

how to measure size of crushed ore in a ...

how to measure size of crushed ore in a pile To measure the level of granule size segregation, until it is crushed at a The iron ore granule piles formed in the simulation and experimental tests Accuracy of Pile Volume Measurement with Photogrammetry

Calibrated Iron Ore at Best Price in India

We offer superior quality Calibrated Iron Ore, procured from the best mines of India. The quality of our Calibrated Iron Ore is highly appreciated by clients and we make sure to stock them in safe conditions in order to maintain their integrity.

Latest Posts

- يؤثر على مطحنة الجبس

- الماس الكسارات مصر

- حفر معدات التعدين من السودان

- مصنع لتجهيز الحجر الجيري في الجزائر

- معدات تكسير الصخور أنجولا

- معدات التعدين و التصنيف و التصنيف العراق

- طحن الكربون لإخراج الذهب

- آلة تكسير موجة الصوت

- المحجر سحق عملية الفرز

- مصانع معالجة الرمل لتلوين الرمال

- فصل الذهب الغرينية تتحرك مصنع

- كسارة مخروطية للإيجار في ولاية أوريسا

- استخدمت تعقب الحجر المحمول كسارة

- الحجر الجيري الفك سعر كسارة

- حجر الميزانية محطة كسارة

- gipsum menghancurkan pabrik di semen dijual

- crusher suppliers in south africa

- rod mill foundation design

- mine belt conveyor cost list in seoul

- e type coal mills

- vertical mill suppliers for tph line india

- city seed crushing industries ltd

- crusher bauxite cone

- pembuatan bubuk oleh proses penggilingan bola kering

- buy ultra perfect s 2l wet grinder online at

- mining equipment ball mill

- coal mill atox italy bhutan

- manganese in plant

- crushing amp screening plant tender in india

- bijih emas grinding mill afghanistan