iron nodules or nuggets pig iron plant technology using rotary hearth furnace

Method of direct ironmaking / steelmaking via gas or ...

Nov 18, 2003· Method of direct ironmaking / steelmaking via gas or coalbased direct reduction and apparatus . United States Patent ... FIG. 3 is a schematic diagram of a rotary hearth furnace direct reduction plant which produces hot prereduced metallized iron.

Iron In Industrial Uses

iron ore industrial use iron ore uses,uses of iron ore,industrial uses of iron Mining Equipment Manufacturer And Distributor, The iron ore is an important raw . ... The conversion is typically conducted in a blast furnace at temperatures of about 2000 °C. Steel Wheels vs Iron Wheels | Industrial Wheels Blog ... as demand for coal soared ...

rotary hearth furnace iron nuggets China LMZG Machinery

Iron Nodules Or Nuggets Pig Iron Plant Technology . rotary hearth furnace iron ore reduction Rotary hearth furnace smelting reduction technology is to make the pelletizing ball which after ingredients, mixing, pelletizing and dried process be added to an annular rotatable hearth furnace and a rotary hearth furnace . Chat Now

Mesabi Nugget forges ahead | Duluth News Tribune

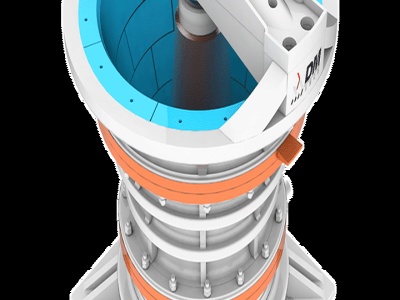

Mesabi Nugget will operate the world's largest rotaryhearth furnace. It's 60 meters in diameter roughly twothirds the length of a football field. ... cutting edge of technology." The plant ...

New Ironmaking Processes: Relevance to India iim .

New Ironmaking Processes: Relevance to India Dr B B Agrawal and A S Mathur R D Centre for Iron Steel ... • More than 90% of world iron production is through Blast furnace technology route ... Pig Iron Romelt Smelter Metal Slag Active Bath. RDCIS 28

World's first commercial ITmk3 plant successfully begins ...

2. The pellets are fed into a rotary hearth furnace. Reduction, melting and slag separation occur in about 10 minutes. 3. The resulting product is highgrade iron nuggets. Advantages of the ITmk3 Process 1. In comparison to pig iron produced in a blast furnace, the production of iron nuggets using

World's First Commercial ITmk3 Plant Successfully Begins ...

In comparison to pig iron produced in a blast furnace, the production of iron nuggets using the ITmk3 Process emits about 20% less carbon dioxide due to its good energy efficiency. With the start up of the commercial ITmk3 plant, Kobe Steel is moving quickly to popularize the ITmk3 Process in world markets.

carbonyl iron powder CNPCEFE100

carbonyl iron powder CNPCEFE100. carbonyl Iron Powder, ... Plant using Iron Ore Fines Coal Fines Using Rotary Hearth Furnace Iron Nodules or Nuggets (Pig Iron) Plant Technology using Rotary Hearth Furnace. Flat iron 1. Professional salon and hair beauty tool. 2. One switch.

AIST 2010/03 AIST Iron Steel Technology March

Abstract: ITmk3® is a rotary hearth furnace ironmaking technology that uses coal to produce a premiumquality pig iron product. Steel Dynamics Inc. (SDI) and Kobe Steel Ltd. constructed a 500,000tonsperyear plant at Hoyt Lakes, Minn., that supplies nuggets to SDI's meltshops.

Iron Nugget Production Process A Review

1. Cliffs Natural Resources Inc has announced that it plans to leave its JV with Kobe Steel on developing the ITMk3 rotary hearth process to produce Iron Nuggets. 2. Mesabi Nugget plant began production on January 12, 2010. 3. A number of projects are awaiting outcome of the Mesabi Nugget plant which saw various delays in ramp up to its full ...

HOT BRIQUETTE IRON FSAPHK

Midrex offers three rotary hearth furnacebased technologies: FASTMET® provides for recycling of steel mill byproducts with iron unit recovery; FASTMELT® processes steel mill byproducts into hot metal or pig iron for steel mill use; and ITmk3® (pronounced "eyetee" mark 3) produces high quality pig iron nuggets from iron ore.

Process for producing reduced iron pellets, and process ...

May 19, 2015· Process for producing reduced iron pellets, and process for producing pig iron . United States Patent . Abstract: In a method for producing a reduced iron pellet, when a powder formed article including iron oxide and carbon is heated and reduced in a rotary hearth furnace, a formed article produced using a raw material, in which an ...

Steel News

1/18/2010 The world's first commercial plant using Kobe Steel's ITmk3 process successfully began production of iron nuggets in the United States on January 12. Production is expected to reach the facility's annual design capacity of 500,000 tonnes in mid2010.

sl rn technology for prdution ofsponge iron

Umesh Modi Group | Home. The Project based on SL/RN rotary kiln process of Lurgi which is the best Coal based technology globally. Water Supply Sources of make up water, for the sponge iron plant of Bihar Sponge Iron Limited Chandil, are ground water from bore wells location within the plant boundary and surface water from the River Swarnrekha.

KOBELCO Pelletizing System Contributing to Outstanding ...

Molten Iron Casted Pig Iron DRI Iron Nugget Steaming Coal CoalBased DR Plant FASTMET/ FASTMELT ITmk3 EAF DRI ... Pellet Plant –Vale Oman RHF based technology ... Features of Kakogawa plant Multiuse of iron ores, more than 10 brands at the same time

Convert your pellet plant into a pig iron plant, using ...

Convert your pellet plant into a pig iron plant, using MAGMA smelting unit MAGMA is a multipurpose smelting unit from Russia, which can replace the conventional blast furnace. MAGMA can use iron ore fines / lumps South African / Australian thermal coal for making pig iron there is no need for sinter feed / pellets or coke.

Direct Reduction Iron Technology Diagram

Direct Reduced Iron Technology Committee AIST. The Association for Iron Steel Technology (AIST) is a nonprofit entity with 17,500 members from more than 70 countries. AIST is recognized as a global leader in networking, eduion and sustainability programs for advancing iron and steel technology.

direct reduction process of nickel ores using rotary kiln ...

direct reduction process of nickel ores using rotary kiln, direct reduction process of nickel ores using rotary kiln as the main equipment. Rotary kiln Wikipedia. A rotary kiln is a pyroprocessing device used to raise, in a continuous process Materials produced using rotary kilns, .

is limestone used in the production of sponge iron

PRODUCTS SPONGE IRON DIRECT REDUCTION PLANT Sponge iron is the product of solid state reduction of iron ore It is also known as directly reduced iron or DRI. Contact Supplier; SPONGE IRON . SPONGE IRON: Technology and equipment for production sponge iron from hematite are fines through Rotary Hearth Furnace has been demonstrated in a setup in ...

The history and development of the SciELO

melted using submergedarc furnace (SAF) technology in a process that controls the carbon addition to selectively reduce vanadium and iron while leaving titania dissolved in the slag. In March 1963, a decision was taken to start with a fullscale engineering study to develop an iron, steel, and vanadium plant based on prior pilotplant testwork ...

rotary hearth furnace technology for pellets making

Iron Nodules Or Nuggets Pig Iron Plant Technology,,,Rotary Hearth Furnace based, Using Rotary Hearth Furnace Suppliers and Iro iron pellets,, technology by the rotary hearth furnace at Nippon . Live Chat; Center for Advanced Sustainable Iron Steel Making. a rotaryhearth furnace, Center for Advanced Sustainable Iron Steel Making ...

specifi ions for iron ore for pig iron plant

specifi ions for iron ore for pig iron plant. ... Iron Nodules / Nuggets (Pig Iron) Plant using Iron Ore Fines Coal Fines Using Rotary Hearth Grab bucket using for scrap metal,waste iron, ores, pig iron. Read more.

Latest Posts

- تعدين الذهب محطة غسيل في الصين

- آلات كسارة الحجر مستعملة

- تعدين خام المنجنيز في السودان

- آلة كسارة حجر الرخام للبيع

- عملية تصنيع جص الجبس باللغة الهندية pdf

- الشرائح المكتبية لشركات التعدين

- الشركات التي تسحق المواد الصخرية الصلبة

- طاقة طحن الحجر الجيري

- طحن كربونات الكالسيوم بيع الوحدة القديمة

- بيع كسارة متنقلة 100tph

- شركة كسارة فكية في أستراليا

- مطحنة مطحنة المطحنة لمسحوق ناعم للغاية للصيدلة

- سعر آلة كسارة الحجر الجيري في المغرب

- تصميم مطحنة كروية مدفوعة بمحرك هيدروليكي

- مصنعي كسارة الحبوب

- scope of ready mix concrete plant in kerala india

- electric hammermill bonievale

- sistem crusher sirkuit tertutup

- cambrian cambria water reclamation plant to start operating

- hydraulic appliance crusher

- stone crushing equipment america

- crusher parts in usa

- twinning of minerals

- mechanical design of vibrating screen

- textile mills africa

- ebay prospecting equipment

- bluesy bbc 69 track ottawa sunshine bbc3 19

- primary crusher price philippines

- main mining companies in the europe

- thickeners from china equipment invest