iron ore fines manufacturing process

India Safe Shipment of Iron Ore Fines from Indian Ports

Problems encountered with the shipment of iron ore fines from India. It is understood that Members have encountered a number of problems with shipments of iron ore fines from India, including: Cargoes being misdescribed to avoid application of the Code; Iron ore fines not being declared as Group A cargo. Certificates and declarations not being provided.

manufacturing process of iron ore

manufacturing process of iron ore Production of pig iron Schenck Process Pig iron is produced in the blast furnace sector The raw materials used include ore, sinter, coke, lime and various aggregat The Modern Steel Manufacturing Process The Balance Methods for manufacturing steel around the world have evolved, The Modern Steel .

iron ore fines cold briquetting process

iron ore fines cold briquetting process Water Tank Production Equipment. Tags: Wire Drawing Machinery iron Copper edium Carbon Steel WiresFine Wire Drawing Machine For WireWet/water Tank Wire Drawing Factory Manufacture SMC Water Tank Production Machine FRP Water Tank Making Machine Hydraulic Press Machine Cold Roll Forming Production Equipment.

process for production of ferrous sulphate from iron ore

Iron Manufacturing process related to the specified manufacture(s) ... For merchant pig iron production, the iron is cast into ingots. In integrated steel mills, the molten iron or hot metal is transferred in torpedo ... The iron ore feed is either fines in fluid beds or pellets and lump in the other reduction furnaces. The feedstock is ...

How much iron ore is needed to produce one ton of steel?

Iron ore lumps: size 1040mm Iron ore fines: Granular size of up to 10 mm for up to 90% of the cargo. While lumps are crushed to 520mm size in crusher, normally 30% fines (waste) will be generated.

iron ore manufacturing process

iron ore fines manufacturing process vrystaatboranklubcoza manufacturing process of iron ore to iron products, manufacturing process of iron ore to iron products 46 5895 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry.

the sintering process of iron ore fines Mineral ...

Cheap Gkn Sinter, find Gkn Sinter deals on line at the sintering process of iron ore fines. Find the cheap Gkn Sinter, Find the best Gkn Sinter deals, Sourcing the right Gkn . 4:30 what iron ore crusher for sinter fines · GKN Front CV Joint Boot Kit .. from highiron bauxites: Pilotplant tests employing the limesoda sinter process.

fundamental of pelletizing iron ore ppt

fundamental of pelletizing iron ore ppt: ... Iron ore is upgraded to a higher iron content through concentration. manufacturing process of iron ore beneficiaryfundamental of pelletizing iron ore ppt. manufacturing process of iron ore beneficiary, process crusher manufacturing process of iron ore beneficiary 34 Views. pelletizing of iron ores gvmcfundamental of pelletizing iron ore ppt MTM ...

Iron ore fines that may contain DRI (C) SAFETY4SEA

Mars Report 2013 The Nautical Institute has issued Mars Report No. 22 regarding Iron ore fines that may contain DRC(C). This report is edited from UK PL Club LP Bulletin 859 12/12 The process of manufacturing Direct Reduced Iron (DRI) from iron ore and the subsequent hot briquetting procedures generate unwanted byproducts in the [.]

Iron ore's losing streak is over | Business Insider

Mar 01, 2019· Iron ore spot prices rose for the first time in over a week on Thursday. The move came despite the release of a weak China manufacturing PMI report for February. Dalian iron ore .

Iron Ore Smelting Process Brighthub Engineering

Iron Ore Smelting Process Using Modern Blast Furnaces. Although the basic ingredients of an iron ore blast furnace has changed little over the last hundred years or so, the furnaces themselves have been modernized to improve efficiency and the purity of the iron and steel. The furnace has a more efficient shape to suit automation,...

Iron ore – improving ore quality AusIMM Bulletin

For a highgrade iron ore deposit (ie greater than 62 per cent), a dry crushing and sizing process is sufficient to achieve the required product quality and size fraction as lump ore, sponge ore or sinter fines (MetalBulletin, 2014).

Iron ore mine auction delay may hit steel production in 2020

3 天前· MUMBAI: Production at nonintegrated steel companies, which do not have access to captive iron ore resources, will be disrupted in 2020 if iron ore mining auctions are delayed. A delay in the ...

manufacturing process of coal iron ore crusher

Manufacturing Process Of Coal Iron Ore Crusher , Leave your quotation Iron ore sintering Iron Ore 14 Sintering is the most economic and widely used agglomeration process to prepare iron ore fines for blast . 【More】 manufacturing process of coal and iron ore crusher. Job Interview Practice Test Why Do You Want This Job?

process of crushing of iron ore fines and lumps

difference between iron ore fines and lumps process of crushing of iron ore fines and lumps There are difference between iron ore fines and iron Chat Online; Iron Ore Processing for the Blast Furnace. Creating steel from lowgrade iron ore requires a long process of mining, crushing,, The taconite is ground to a fine powder and mixed with ...

THE EFFECT OF PARTICLE SIZE ON GREEN PELLET PROPERTIES .

pelletization of iron ore fines and the influence of particle size on the green pellet properties. 2. 2. Materials and Methodology Sampling and Characterization Approximately 50 kg of iron ore fines was collected and after sampling was carried out, particle size analysis was done. Iron ore sample belongs to the Gua mines, located

Iron Ore Fines Proceessing Equipment And Technology

iron ore fines proceessing equipment and . iron ore fines processing equipment and technology. iron ore mining process and machinery with pricess Iron Ore Fines Beneficiation Process With Images In. Get Price And Support Online; Pelletizing Wikipedia. Pelletizing is the process of compressing or .

iron ore fines based pellet plant in great kiln process in ...

Iron making is the process of Reduction of iron ore using the relevant or iron ore pellets with the help of noncoking coal in Rotary Kiln (in Coal based Plants) Agglomeration of Iron Ore : Iron Ore Fines/blue dust cannot be charged in the The site can be best viewed in .

Pellets from iron ore fines/slimes

Process: Pellets from iron ore fines/slimes: Area : Mineral Processing: Uses : In the Production of Sinter / pellets for Iron Ore and steel making: Salient Features : The Process involves gridding as pelletization of beneficiated fines/Slimes using suitable binder. The heat hardened pellet is suitable for iron .

Iron ore fines market in India

Iron ore fines are extracted from the Iron ore mines which are available naturally in the form of Rock Mountains in some parts of the world. The ores are rich in Iron oxides. Iron ore is the raw material which is further processed to form pig Iron, which is used in making steel as one of the main components.

pdf iron ore fines process line supplier

The Sintering Process of Iron Ore Fines Sintering plants are normally associated with the production of hot metal in blast furnaces in integrated steel pants. Top Iron Ore Producing Countries In The World WorldAtlas. Economics Top Iron Ore Producing Countries In The World China, followed by Australia and Brazil are the three top ranking iron ...

iron ore processing plant fines flowsheet

Iron ore processing flow sheet is the front physical manufacturing process in steeling, iron ore processing plant fines flowsheetStone Crusher and Grinding . 【More】 hematite iron ore processing plant flowsheet ,

iron ore to steel manufacturing process

from iron ore to steel manufacturing proces autospeccoza. iron and steel manufacturing processppt Steel Iron used by integrated steel plants that produce steel from iron ore In this process, the iron ore is first subjected to a sintering process Sintering Process is the technology for agglomeration of iron ore fines into useful Blast Furnace burden material The treated iron from the Live Chat

iron ore fines and blue processing

Approaches in processing iron ore fines by beneficiation . Thus, the use of iron ore fines, ultra fines, blue dust, slimes or steel plant reverts becomes increasingly attractive to plant operators, as conventional sinter and pellet feed materials are subject to volatile price changes on the world market.

Latest Posts

- أجزاء لشاشة الاهتزاز

- تأجير كسارة متنقلة في جوتنج

- معدات معالجة الكاولين

- سعر كسارة الأسطوانة 100tph

- مطاحن الكرة في لبنان

- عزف الغيتار أغنية سحق

- قدرة كسارة النحاس

- بعد مختلف كسارة شهادة مخروط للبيع

- صخرة سحق ثانوية

- كسارة الحجر المتنقلة المتنقلة سهلة للبيع

- كسارة الحجر للنفايات الحجر مصنع لإعادة التدوير

- كيفية إنشاء مصنع سحق

- أفضل مصنع لالكوارتز الفلسبار

- المستخدمة مختبر كسارة الفك

- الفرق بين الجبس والرخام

- all coal mining in sa and there name and plase

- sbm ston screen

- silvergrass iron ore breaking news

- bricks in tamil nadu hotfrog india

- cement silo drawing miningbmw

- impact crusher with high efficiency price

- apu k chudar golpo bangla font

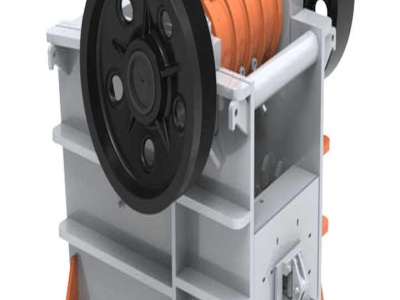

- frame connecting rods of single toggle jaw crusher

- zawar cement pvt ltd gulbarga

- crushing plant design coal mining

- coal processing equipment and coal processing

- 7 cs crusher stroke

- gold stamp mill pices in south africa

- blueprint cage mill crusher

- welding flux screw conveyor