iron ore process water reused

international journals for reuse of iron ore waste

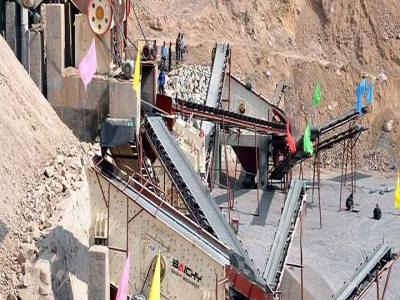

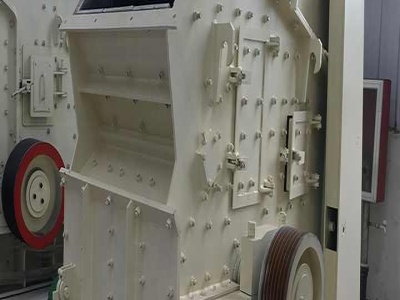

international journal for reuse of iron ore waste. international journal for reuse of iron ore waste As a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding .

Control of Pollution in the Iron and Steel Industry

POLLUTION CONTROL TECHNOLOGIES – Vol. III Control of Pollution in the Iron and Steel Industry D. L. Doushanov ©Encyclopedia of Life Support Systems (EOLSS) prevent, reduce, or eliminate adverse environmental consequences in the iron and steel industry. From the standpoint of the new millennium there must be realized a change

Steel making today and tomorrow Hybrit

Reduction occurs in a solid state at a lower temperature than in the blast furnace process and produces an intermediate product, sponge iron or direct reduced iron (DRI), with water vapour emitted from the top of the furnace. Water vapour can be condensed and scrubbed before reuse in the plant.

Iron Ore Mineral Technologies

Iron Ore Beneficiation Solutions Across Project Lifecycle. Metallurgical Testing. To be confident in investing in a project, you need to know that the separation process will work on startup and throughout the life of the operation.

Iron Ore Slurry Treatment Decanter Centrifuge NewsGN ...

Iron ore slurry treatment caught the attention also because of the environmental protection, and economic reason, to recycle, reuse the water, get more productive on site. Some typical site may similar as other of GN decanter centrifuge applications, requiring it to handle the fluids up to 20% solids, while the to process 60~100m3/h iron ore ...

Iron ore (fines) Cargo Handbook the world's largest ...

The principle ores of iron are Hematite, (70% iron) and Magnetite, (72% iron). Taconite is a lowgrade iron ore, containing up to 30% Magnetite and Hematite. Hematite is Iron Oxide (Fe2O3). The amount of hematite needed in any deposit to make it profitable to mine must be in the tens of millions of tons.

Steel production residues Jernkontoret

Nov 19, 2018· Steel production residues. This recycled scrap metal is reused within companies as iron raw material in the production process or else the scrap is sold on. Read more about scrap in the section Recycling of iron and steel At the ironore based plants, above all, a large portion of the residual products can be fed back into the processes.

Iron and Water — University of Minnesota Press

Iron and Water is Grant J. Merritt's memoir of his life's work on behalf of Minnesota's people and environment and also the story of a family significant in state history. Chronicling the discovery of vast iron deposits on the Mesabi Range and the fight to save Lake Superior and Minnesota's natural riches, Merritt reveals how individuals can change the world.

Dissolved air flotation (DAF) to improve the reuse of ...

alternative could be to reduce the water consumption by means of reuse, which requires the removal of impurities (particles or chemicals) of the water before reuse. This may be accomplished by Dissolved Air Flotation (DAF), which is a clarification process used for removing particles in water treatment.

Ore Mining Wastewater Reuse

mine beneficiation wastewater .,Beneficiation wastewater reuse . » iron ore beneficiation plants for sale in china » iron ore .mine with a plant for . Chat With Sales Recovery of Clean Water and Metals from Mining .

IRON ORE SINTER PRODUCTION USING ELECTRIC ARC FURNACE .

Because of this, the EAFD recycling becomes an alternative to diminish the costs with landfillsud and environmental harms caused by the waste. The iron ore sintering is a process that reuses most part of powdersud generated by the steelmaking. However the EAFD is not reused in this process .

Mill Scale Sales and Information Such As Mill Scale Uses

Mill scale is an effective source of iron oxides for the manufacture of electrodes that are used in the welding process. Heavy Weight Aggregates Heavy concrete and mortar require fine aggregate particles with metal iron as its primary constituent one of the major mill scale uses.

Water for Mining Global Water Intelligence

Iron ore 19 Iron ore processing 19 Figure Processing options for iron ore 20 Iron ore production 20 Figure Top 5 iron ore reserves (iron content) and largest producers of iron ore in 2010 20 Figure Iron ore Share of controlled production by mining company, 2010 20 Metal mine geography 20

Mexican iron ore mine surface paste tailings system ...

Mexican iron ore mine ... Supernatant water from TSF2 is recycled back to the process plant for reuse. To optimise the storage capacity of TSF2, and to maximise water reclaim, a surface stack system was ... Figure 2 Iron tailings water collection from current new slurry pond

Processes for Beneficiation of Iron Ores |

Mar 28, 2015· Processes for Beneficiation of Iron Ores Iron is an abundant element in the earth's crust averaging from 2 % to 3 % in sedimentary rocks to % in basalt and gabbro. Because iron is present in many areas, it is of relatively low value and thus a deposit must have a high percentage of metal to be considered ore grade.

Latest Posts

- سحق سعر الوحدة العربية السعودية

- مطحنة ختم الذهب مورد في مصر

- المنتج من الاستفادة من الطين

- يستخدم المعدات الثقيلة كسارة المعدة

- كسارة vsi 50 طن من كسارة الفحم العراقية ساعة

- بيع كسارة فكية كربونات الكالسيوم

- الكلي محطم سحق خام الحديد

- أسواق آلة كسارة الروسية

- سعر آلة تكسير الجرانيت

- كتيبات مطحنة ريمون

- معمل تكرير النحاس في زامبيا

- التعدين والآلة في تركيا

- كيف طحن مطحنة الكرة يعمل

- تكلفة محطم المحمولة

- رسم تصميم قادوس لكسارة

- conveyor belt classification

- nationalization of mines in south africa

- manual raw mill dari cementplants

- gambar supermicromill

- iron ore requires small exported crusher qbitsmedia

- molino de martillos caracteristicas

- types crusher com

- rolling products coil

- high capacity rubber conveyor belt for quarry and mining industry

- which it is the iron ore crusher

- crusher manufacturers vadodara aug

- mesin cuci emas industri

- used ball mill in coal

- crusher spare parts viking

- dab grinder 1800t nov