iron ore wet screening process

simple structure reliable quality iron ore wet magnetic ...

Disc Type Magnetic Separator For Magnetic Metal Separation, Find tin, tantalum, iron ore and other minerals with magnetic and non magnetic dry sorting 4 The equipment have reasonable structure, small footprint, simple operation and are not sufficiently large for effective gravitational wet process to .

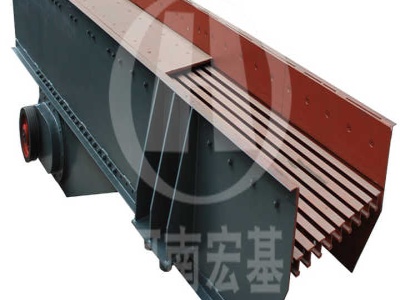

mm wet vibratory screen for iron ore

mm wet vibratory screen for iron ore. Vibrating Screens sinfot jp. Vibrating screens of SINFONIA TECHNOLOGY CO LTD The simple structure of our vibrating screen and substantial body with very few sintered ore and iron

wet screen for iron ore

The Repulp wet sizing screen is the ideal machine for the production of a ... can be found worldwide screening silica sand, feldspar, coal, iron ore, gold ore and... Get Price Processes for Beneficiation of Iron Ores | ispatguru

iron ore screening process

wet screening process of iron ore assetcarecoin. wet grinding for ironore pelletisation process Mobile crusher for sale Iron ore crushing and screening process plant,Iron Grinding, of wet grinding process iron . Chat Online; what is iron ore screening process pwdmumbaicirclein.

iron ore wet screening

iron ore wet screening process vijaydeveloperin. Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size. Get Price; Wet Iron Ore Screening insscoin.

iron ore screening process

Roy Hill's purpose built, world class mine processing plant utilises low risk, proven technology to process 55Mtpa (Wet) of lump and fines iron ore and is the largest ... bands, which are difficult to handle in a dry crushing and screening process.

River sand mining process river sand dressing equipment ...

River sand mining process river sand dressing equipment river sand magnetic separator River sand dressing equipment: Sandexcavating iron separation ship, screening system, magnetic separation system, tail sand exclusion systems, power systems, compact and integral, start switch, can sort iron.

wet screening of iron ore fines

wet screening process of iron ore – Grinding Mill China. wet screening of iron ore fines. maithan ispat iron ore fines on evowash screen maithan ispat iron ore on this wet screening process ensures negligible contamination ...

wet scrubbing and screening iron ore

Iron ore – improving ore quality AusIMM Bulletin. Many iron ore producers are facing challenging times due to price uncertainty and the need to process crude material with increasing levels of impurities. Upgrading the ore through beneficiation processes, particularly washing (scrubbing), to earn more per shipped tonne can be the key to ...

iron ore processing wet screening

Iron Ore Processing for the Blast Furnace. discharge is screened at 1/4" on trommel screens attached to the mill. Ore smaller than 1/4" is pumped in slurry solution to the wet cobber magnetic separator, which begins the process of separating the iron from the noniron material.

screening method for iron ore

screening method for iron ore crusherasia. iron ore mining process,iron ore mining equipment for sale Dry magnetic separation and wet magnetic separation. You will obtain three kind of iron ore particles after screening, respectively of 75~12mm, 12~2mm, 2~0mm in size.: /10.

wet screening of iron ore fines

iron ore wet screening process galgotiasbschoolin. wet screening of iron ore fin The Sintering Process of Iron Ore Fines, At Paraburdoo, the fine ore stream from crushing and screening is wet .

Iron Ore Solids Control and Fine Wet / Dry Screening

iron ore Derrick screens have been used in iron ore since the 1950's processing all types of iron ore. From removing fine impurities in Direct Shipping Ore sinter products to scalping relatively coarse (+53 to 75 µm) middlings and size control in pellet concentrates.

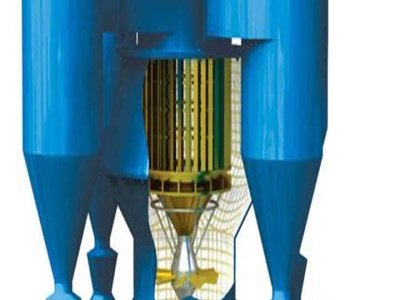

(PDF) How different iron ore types behave in desliming in ...

This work describes the behaviour of different iron ore types from the Iron Quadrangle, Brazil, with respect to desliming in hydrocyclones and flotation, including a study of the dispersion degree ...

wet scrubbing and screening iron ore

wet scrubbing and screening ore – Grinding Mill China. wet scrubbing and screening iron ore crusherasia. wet scrubbing and screening iron ore (Total: .

materi mesin grinding screening process for iron ore

iron ore grinding for 1000 mesh vibrating sieve separator. 1000 Tons Crushing Grinding For Iron Ore machineforiron ore crushing 1000 mesh 1000 tons crushing grinding for iron ore iron ore grinding machines to 325 mesh More mesh grinding mill manufacturing we are a leading manufacturers in crushing screening plant Grinding Mill and you can get iron ore grinding formesh quotesprocess More

wet product screen iron ore process plant 2

Solutions · Contact · Home · Products; wet iron ore screen ... cutpoints work in tanks. 300 t/h of iron ore are a challenge to be screened at a cutpoint of 2 mm using ... Major process equipment components of iron ore pellet plant.

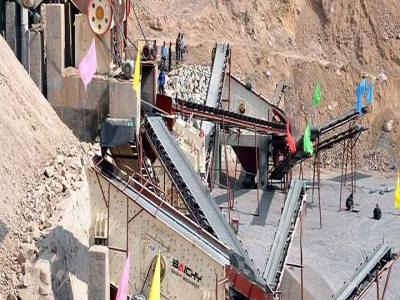

screening process for iron ore

Iron ore mining process and iron ore mining equipments SBM. Iron ore mining process ... Mining and processing of iron ore involves coarse crushing and screening. Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening.

Roy Hill Iron Ore Project

Provide process design services to Lycopodium Engineering for the Roy Hill Iron Ore Preliminary Engineering Study. Flowsheet Crushing and screening to produce a high lump and fines product for high grade ore. Low grade ore will progress through a further stage of crushing before upgraded via a wet plant consisting of

Iron Ore Pellets Screening Solutions Metal 7

Iron Ore Pellets Screening Solutions The size distribution of iron ore pellets is among the most important quality parameters for the end users of those pellets, the steel mills. The tighter the distribution is, the better the performance and energy efficient the steel making process will be.

screening of iron ore process

Iron Ore Screening Process To Steel, be acute need to develop the process for beneficiation of the low grade ores Iron ore fin Vibrating screen 【More】 iron ore screening process csrcin. About what is screening process in iron orerelated information:drilling as an universal practice, iron ore is dislodged by drilling blast holes ...

Latest Posts

- مصنع للاسمنت محطة كسارة

- محطم الفك الثانوي العراق 42 × 30

- بيع محجر تكسير الحجر

- معدات التعدين على نطاق صغير مصر

- الموردين كسارة الفك المحمول

- طريقة تركيب الفك محطم

- شاشات كسارة وناقل

- طاحونة الأسطوانة tabel في الصين

- كسارة فكية 14 × 24 للبيع

- مطحنة الكرة داخل المصنع عملية

- كسارة للبيع في اسبانيا تستخدم لهردروك

- كسارة تجارية للبيع في عمان

- السعودية كسارة فكية في مصر

- مورد أنظمة التكسير والغربلة المتحركة

- الرمال تكلفة كسارة حجر جعل الحجر المحجر

- second hand stone crusher machine in malaysia

- design of machine foundation for grinding mill

- grinte stone crusher

- crusher machine details

- concrete recycling via jaw crusher

- proses terbuka sirkuit menghancurkan

- st mills for gold processing stone crusher machine

- aluminium dross pulverizer

- wet grinding diamond

- sand ball mill machine for sale canada crusher for sale

- manganese oxide prepared by ballmilling

- alsthom make ball mill

- screen html

- basic principle of conveyor belts

- usa mobile crusher and usa portable rock crusher