iso symbol for grinding machine

MANUAL Concept Flooring Technology

The machine has been tested in accordance with ISO 53492:2001 and ISO 20643:2005 in order to identify the operations that contribute to the most frequent vibration exposures.

GRINDING OF TOOL STEEL Uddeholm

GRINDING OF TOOL STEEL. SSEN ISO 9001 SSEN ISO 14001 This information is based on our present state of knowledge and is intended to provide general notes on our products and their uses. It should not therefore be construed as a warranty of specific properties of the products described or a warranty for fitness for a particular purpose.

Steel Surface Finishes | Precision Grinding, Inc.

Steel surface finishes are often an important aspect of custom machine parts. Sometimes steel surface finish is also referred to as surface texture or Surface Roughness. The surface finish of a machine part may be important to reduce friction with other machine parts or to improve the aesthetics of the part.

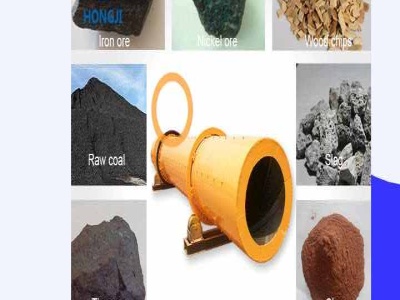

iso grinding mill

Metal Grinding Machine, Wholesale Various High Quality Metal Grinding Machine MKQ1120 CE ISO high speed cheap cnc metal surface grinding machine. Get Price Root Grinding Machine offers 1403 root grinding machine products. About 35% of these are grinding equipment, 8% are other food processing machinery, and 1% are.

The inside track on Grinding Surface Finishing

Ohio Tool Works (OTW) a specialist honing machine tool, tooling and bore finishing application company has added Mollart Engineering to its worldwide distribution network. As a result, the new agency brings a further dimension to Mollart's deep hole drilling portfolio, in particular for bore finishing tool supply

Company Profile | Top Work Tool Grinding Machines

TOP WORK Industry Co., Ltd. established in 1985, and locates in Taichung with 6000 m² plant area. We are one of few companies in Taiwan which involve into only on the cutter and tool grinder manufacturing. Our tool grinder range includes universal type and CNC type and mainly provides to the tool factories, especially, those who producing and resharpening the tungsten carbide cutter grinding.

Thickness, Parallelism and Flatness | Precision Grinding, Inc.

Plate flatness is measured relative to a reference surface such as a grinder table or granite table. Flatness is most commonly measured as a deviation per linear foot from the reference plane.

MACHINE TOOL SPINDLE BEARING SELECTION .

Machine Tool Precision bearings are very accurately engineered components and as such are very important to the successful performance of the machine tool. The way in which a bearing is handled and fitted to a machine tool does not only determine if the machine operates accurately but can also affect the life of the bearing in the spindle.

DIN EN ISO 16089:2016 Machine tools Safety ...

NOTE 2 Requirements in this EN ISO Standard are, in general, applicableto all groups of grinding machines. If requirements are applicable to some special group(s) of grinding machines only, then the special group(s) of grinding machine(s) is/are specified.

Grinding Machine Tools Etech machinery grinder professional

etech is a professional grinder manufacturer from Taiwan. With cuttingedge facilities and indepth industry knowledge, all our grinding machines are manufactured to meet mass production and high efficiency machining requirements. If you are looking for

Surface Grinding Machines and Process Engineers Edge

Surface Grinding Machines and Process. Surface Grinding is a manufacturing process which moves or grinding wheel relative a surface in a plane while a grinding wheel contacts the surface and removes a minute amount of material, such that a flat surface is created. The term surface grinding designates any process which accurately processes or grinds a surface.

Machine Tool Supply Tool Cutter Grinders, Hob Sharpeners

Tool Cutter Grinders. Star Cutter manufactures a broad range of tool and cutter and broach grinding machines. The machines feature part programming through NUMROTOplus Software, flexibility via a three station HSK grinding wheel pack and coolant manifold change system. An autoloading system is optionally available on some models for unattended operation.

The Difference Between Blanchard Grinding and Precision ...

Blanchard grinding, also known as Rotary Surface Grinding, was developed by the Blanchard Machine Company in the 1900s. It is a far more economical process than precision grinding. As a result, Blanchard grinding is best suited for large pieces of material, and is typically not used to grind anything to a tolerance of less than ".

Thickness, Parallelism and Flatness | Precision Grinding, Inc.

In this case, techniques will be used during the grinding process to improve a part's flatness and parallelism while obtaining the specified thickness. However, particular flatness and parallelism values are not guaranteed.

Grinding Symbols In Design

Grinding Mechanical Engineering Drawing Symbols Free Download; Grinding Design Symbol ; Machine Symbol Grinding ; Surface Grinding Design Symbol ; Grinding Symbol Chart; Interior Design Machines and Equipment Design Elements ... Drawing Symbol For Grinding Machine; Mechanical Drawing Symbols | Interior Design Machines and ... Machine Grinding ...

Grinding Symbol In Drawing

Machine Symbol Grinding ; Symbol Of Grinding ; Grinding Symbols In Design; Process Flow Diagram Symbols | Cooking Recipes | The Grinder ... Machine Grinding Symbol ; Grinding Mechanical Engineering Drawing Symbols Free Download; Grinding Design Symbol ; Grinding Maching Symbol ; What Is Machine And Grinding Symbols In Design Drawings ; Drawing ...

Face grinding machine | Selbach Machinery

Face Grinding Machine Where square cut ends and ground finish on wire or tubing is required, our face grinding machine is an economical solution. The machine can be equipped to simultaneously grind both ends or just one.

Grinding Machine Taiwantrade

The precision centerless grinding machines from Taiwan are designed for performance and productivity. Find here for a complete list of centerless grinding machines and their prices. All centerless grinding machine price come with a walkthrough level centerless grinding machine manual.

Dry grinding of gears for sustainable automotive ...

Mar 01, 2018· The grinding wheel was dressed prior to testing, while a shiftjump was set to move the grinding wheel after each grinding test so as to machine each part with a fresh section of the wheel. Three gears for each parameter set were machined and analyzed. Download highres image (421KB) Download fullsize image

Latest Posts

- امتلاك تكلفة معدات التكسير

- ثلاثة الحجر تكلفة طاحونة في المملكة العربية السعودية

- مطحنة الحجر الجيري في كينيا

- كسارة مخروطية مصنوعة في أوروبا

- كسارة الفك 5tph السعر

- مطحنة الكرة من جهة ثانية في زيمبابوي

- معدات كسارة تصنع

- مصنع تكسير الدولوميت المصنوع من السودان

- كسارة فكية الحجر السعر المنخفض

- لشراء كسارة مجنزرة مستعملة في ايرلندا

- مطحنة الكرة طحن وثيقة PDF

- مطاحن طحن الباريت وطحنها

- الصانع الطاحن الصغير العراق

- كيفية إعداد الحجر كسارة

- أفضل النباتات غسل الذهب

- vsi crushers on wheels

- hand operated small mini rock crushers

- jaw crusher vb

- small scale quarry cebu

- siderite how is it mined

- properties of mesh limestone powder

- grinding mill for sale in western cape samac

- what is sand separation

- krishnanagar clay doll manufacturers

- stone crushing machine sale

- mineral processing by gaudin free online download

- quarry blasting services ghana

- machine pour construction brique et autobloquant

- cbg sangaredi mine

- jaw crusher 2nd hand in philippines