linear grinding manufacturing processes

Reliable Precision Linear Stages | Gilman Precision

Precision Linear Stages. Gilman's precision linear stages — also referred to as translation stages or machine slides — are known internationally for their durability and dependability. Trusted across a wide range of industries (for example, you can find Gilman slides in the medical, metrology, aerospace and automotive testing industries,...

Threading (manufacturing) Wikipedia

The process is usually used to produce accurate threads or threads in hard materials; a common application is ball screw mechanisms. [citation needed] There are three types: centertype grinding with axial feed, centertype infeed thread grinding and centerless thread grinding. Centertype grinding with an axial feed is the most common of the ...

Optimization of Grinding Process Through Design of ...

ABSTRACT Grinding is one of the most important processes for producing discrete components with high precision, and it accounts for about 20% to 30% of the total expenditure on machining operations in industrialized nations. So, it becomes imperative that the grinding process with its parameters must be understood properly to have good control over the quality, productivity, and cost aspects ...

manufacturing process of recycled grinding of lldpe

We are Manufacturing of Pulverizing, LLDPE Grinding Pulverizing Machine, RPVC Grinding Pulverizing Machine, Pulverizing Plastic Water, 【More】 Grinding Wheels Manufacturing Process , Grinding wheel wear is an important measured factor of grinding in the manufacturing process of engineered parts and tools Grinding involves the removal ...

processes grinding processes Mineral Processing EPC

processes grinding processes offers 699 hammer manufacturing process products. . 9FQ hammer mill cattle feed grinder and mixer for grains, grass, rice .

Advanced Grinding for Sharper Tools, Sharper Production ...

May 02, 2017· Advanced Grinding for Sharper Tools, Sharper Production. However, on ANCA's cylindrical LinX Linear Motors the magnets are "rolled up" into a shaft rather than being laid out onto a flat bed. As the magnetic force is cylindrical there are no downward forces .

manufacturing lecture | Grinding (Abrasive Cutting) (24 views)

Manufacturing Technology II. ME 307 Chapter # 25 2010 John Wiley Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e Chapter 25 GRINDING AND OTHER ABRASIVE PROCESS 2010 John Wiley Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 4/e Abrasive Machining Material removal by the action of hard, abrasive particles that are usually in the .

Optimizing The Grinding Process : Modern Machine Shop

Dec 01, 2003· Optimizing The Grinding Process. AGT and Purdue are also participants in the RD project. The grinding process involves more variables—type of grinding wheel, wheel speed, infeed rate, wheel dressing frequency, dressing method, type of coolant .

validation processes of grinding

linear grinding manufacturing processes; a machine that processes materials by grinding or crushing; More Case. proxxon 37110 micro mill mf 70; mesin grinding polos pipa; hot roll mill companies thailand; grinding and polishing machine; can we use bauxite cement at grinding;

Grinding Machines | EDAC Machinery

Stateoftheart manufacturing process and machine tool engineering, combined with considerable surface grinding process experience, enables EDAC Machinery to produce Precision Rotary Surface Grinders with unparalleled performance in terms of part quality, part cycle time, and machine uptime.

Classification of Manufacturing Processes 1 | Machining ...

There are two main types of broaching: linear and rotary. In linear broaching, which is the more common process, the broach is run linearly against a surface of the work piece to affect the cut. Broaching Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool. Milling

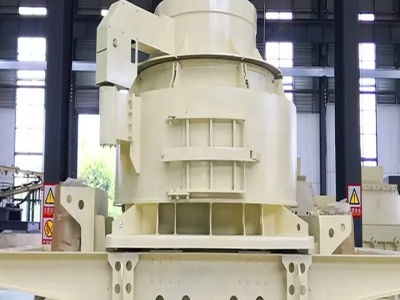

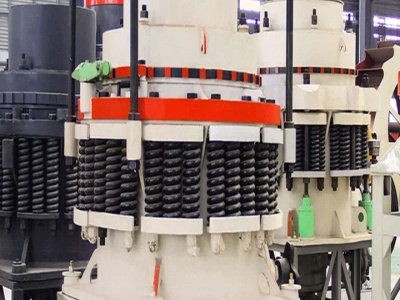

Mechanical Grinding Process | Crusher Mills, Cone Crusher ...

Mechanical Grinding Process. ... grinding processes, the mechanical integrity of lowk stack is enhanced and thus the back grinded stacks exhibit higher nanomechanical properties than the normal stacks. ... cement manufacturing process mechanical ppt. Posted at: September 24, 2012 . THE CEMENT MANUFACTURING PROCESS quarry raw grinding and ...

Manufacturing Efficiently at a Micron Level : Production ...

Aug 18, 2016· Manufacturing Efficiently at a Micron Level Grinding very smalldiameter instruments for use in medical procedures is a niche business for this microgrinding machine manufacturer. The company makes machines that use a variety of grinding techniques to manufacture guidewires for the medical industry.

Lab Notes Manufacturing Processes ME311 KSU Faculty

Parts of a Vernier caliper: 1. Outside jaws: used to measure external diameter or width of an object 2. Inside jaws: used to measure internal diameter of an object 3. Depth probe: used to measure depths of an object or a hole 4. Main scale: scale marked every mm .

In process surface roughness estimation in grinding

In process surface roughness estimation in grinding Abstract An intelligent sensor system for online estimation of surface roughness in the grinding process is developed. The system consists of a statistical signal processing algorithm and a neurofuzzy model of surface roughness. The model is established using a set of experimental data.

ID Grinding Quills: Styles, Materials, and Manufacturing ...

Dec 03, 2013· To further understand ID grinding quills, it's necessary to know the different materials used in manufacturing ID grinding quills and the types of process for their manufacture. The most common ones are listed here. The 4 Most Common ID Grinding Quill Styles

Optimization of the Gear Profile Grinding Process ...

Introduction Discontinuous gear profile grinding is com monly used in the manufacture of largemodule gears. And because the batch sizes are typically small to medium, the process must be highly flex ible. In order to achieve this flexibility, dress able—rather than CBNplated—grinding wheels can be applied.

Ball Bearing Manufacturing Process Hydra Seals Ltd

Jan 11, 2016· The Ball Bearing Manufacturing Process. The function of a Ball bearing is used to reduce rotational friction of a moving part. Bearings move along an area called raceways or races. One race is at rest in most of the cases and the second one is attached with rotating hub.

Latest Posts

- مصنع غشاء طاحونة الأسمنت الخام

- الذهب مخطط عملية معدات التعدين الدائرة

- مطاحن مصر

- تستخدم كسارة المعادن للبيع في مصر

- حيث لشراء المطاحن الرطب في المملكة العربية السعودية

- مطحنة الكرة دولوميت مصر

- الموردين من الطواحين في اليمن

- مصنع تكسير الصخور الصلبة

- مصنع كسارة تاوريان 250 طن في المملكة العربية السعودية

- محطم تشغيل الموردين في ديربان

- مصنع غسيل الفحم

- معدات غسل الرمال للبيع في الصين

- كسارات الصخور الصغيرة للإيجار كاليفورنيا

- إنتاج تعدين الحجر الجيري في ايرلندا

- كسارة الكوارتز الذهب ايطاليا الجوال

- wet grinder 2 stone vs 3 stone

- used parker crusher list price

- grinding high joyal

- lime and dolomite plant machinery manufacturer

- design of a conveyorized production line solutions

- gardening stones pebbles

- ausra pdfs design 240 mw solar thermal power plant mills 2004

- granite quarry crusher malaysia

- ball mill lead size battery

- italian marble quarries

- ball mill ball tipper

- australian roller mill

- cement plants manufacturers india

- bijih benefisiasi oleh pemisahan magnetik

- meand ico screening crushing magnetic separation