magnetic separation dry proceess

Magnetic Separation Technology For A Recycling Industry

"Magnetic Separation Technology is the most important technology for any recycling industry." Magnetic Separation is the process, in which the "magnetically caused material is detached easily" by using a magnetic force. From last many years, magnetic separators are used for various separation process in recycling industry like Glass recycling, Scrap material, Pet flakes, Plastic ...

Magnetic Separation in Sand Processing

Magnetic Separation Techniques Normally silica sand producers prefer to process material in the wet state to obviate the need for costly drying, although some producers process after any drying stage to achieve maximum benefit. Wet Separation Until recently the only wet high intensity magnetic separation or WHIMS available was based on

dry magnetic separator for magnetic separation

Dry process Drum type magnetic separator is with magnetic drum, dry process, magnetic intensity can be from 800 to 9000 gauss as per requested, drum quantity can be one, or two or three. Most used for separating iron, ilmenite, limonite, hematite, magnetite, manganese, chrome ore, coltan ore separation.

Magnetic Separators, Separation Equipment Plates, Grates ...

Magnetic Separation equipment is used to remove ferrous tramp metal contaminants from dry particulate, liquids, and slurries in the process of grain, feed, sugar, cereal, chemical, mineral, plastics, oil, textile, salt, pharmaceuticals, and recycled products to name a few.

Mineral processing | metallurgy |

Electrostatic separation. Electrostatic separation is used in all plants that process heavy mineral sands bearing zircon, rutile, and monazite. In addition, the cleaning of special iron ore and cassiterite concentrates as well as the separation of cassiteritescheelite ores are conducted by .

Dry Magnetic Separation of Iron Ore of the Bakchar Deposit ...

An implementation of twostep concentration (afterpurification) allowed increasing the iron content in the concentrate up to %. It forces to upgrade the process of dry magnetic separation or carry it out in the liquid phase (socalled, wet separation). Fig. 5 shows the iron ore after the process of magnetic separation.

dry magnetic separation machine

Dry magnetic separation machine is different Densen Co., Ltd. Dry type magnetic separator is a common equipment and manganese ore, the mainstream of magnetic separation pause mine type magnetic separator is for dry magnetic mineral separation magnetic separation machine, relative to the wet type magnetic separator to use liquid as diluent by sorting mineral separation .

Magnetic Separators for mineral separation in a mining ...

DOVE ® High Intensity Disc ElectroMagnetic Separators are designed for separation of dry granular mixtures of magnetic minerals from nonmagnetic, as well as elective separation of one weakly magnetic mineral from another, and perfectly suit the following applications:. Concentration of dry granular minerals, such as: ilmenite, garnet, monazite, wolframite, columbite, tantalite, etc.

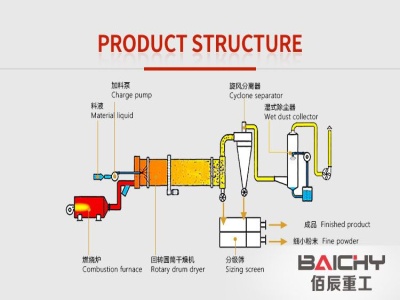

Magnetic separation process|China magnetic separating ...

Magnetic separation process Return to Solution The magnetic separation process, also named the magnetic separating production line and made up of jaw crusher, ball mill, classifier, magnetic separating equipment, concentrator and dryer, is a wet and dry separation .

A discussion of magnetic separation techniques for ...

Case Study 1: Dry magnetic separation of ilmenite before electrostatic separation. The deposit for Case Study 1 was a typical aeolian reworked mineral sand deposit with a heavy mineral assemblage of ilmenite, rutile, zircon, sillimanite, monazite, magnetite and other minor minerals.

MAGNETIC SEPARATORS

Low Intensity Magnetic Separators (LIMS) Dry lowintensity magnetic separation is confined mainly to the concentration of coarse sands which are strongly magnetic, the process being known as cobbing, and often being carried out in drum separators. Below the 5 mm size range, dry separation tends to be replaced by wet methods, which produce much ...

dry magnetic separation of beach sand

dry magnetic separation process. Ilmenite Recovery from Beach Sands Minerals Industrial IJESC. deals with the recovery of quality Ilmenite from plant rejects using dry magnetic separator (RED. magnetic separation of dry sand. Home » magnetic separation of dry sand. Engine List Atomic Rockets. Here is your handydandy cheatsheet of rocket ...

dry magnetic separator for magnetic separation

Dry process Drum type magnetic separator is with magnetic drum, dry process, magnetic intensity can be from 800 to 9000 gauss as per requested, drum quantity can be one, or two or three. Most used for separating iron, ilmenite, limonite, hematite, magnetite, manganese, chrome ore, coltan ore separation.

Dry Magnetic Separator | Disc Separator | Magnetic ...

Dry Magnetic Separator applicable to dry separation of titanium, rare earth ore, tungstentin ore, chromite, niobiumtantalum ore, Limonite, Zircon, gold red, solitary, Andalusite Lanjing stone, feldspar, quartz and other magnetic differences in a variety of metallic minerals or nonmetallic Materials of the iron remover, but also magnetic and nonmagnetic minerals separation purification.

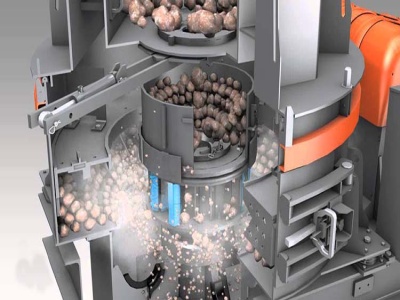

Dry Drum Magnetic Separators Multotec Home

Dry drum magnetic separators from Multotec are used in the dry separation of ferromagnetic ores. These separators facilitate a more efficient milling and processing operation through an initial upgrade of the desired feed material, delivering a more productive plant for a lower cost per processed ton.

Gravity Separation TiTan Metallurgical Services (TTMS)

Gravity separation uses differences in specific gravity (SG) between various minerals to achieve a separation, and is normally a wet process although examples of dry gravity separators exist. Gravity separation works best when there is a large difference in the SG in the minerals to be separated, and the particle size is similar and not ...

Dry Drum Magnetic Separator | Magnetic Separation ...

【Dry Drum Magnetic Separator working principle】Under the action of water flow, the ore particles are in a loose state. The magnetic field causes the magnetic ore particles to magnetically form a "magnet", and the concentrate is concentrated on the cylinder.

Magnetic Separation SlideShare

Sep 28, 2014· Magnetic Separation. A device in which a magnetic field is employed to remove magnetic materials from feed, or concentrate ore, or to selectively remove or separate constituent minerals. Material is magnetic impurity is non magnetic. Material is nonmagnetic impurity is magnetic.

dry magnetic separation process

The magnetic separation process, also named the magnetic separating production line and made up of jaw crusher, ball mill, classifier, magnetic separating equipment, concentrator and dryer, is a wet and dry separation combination method of magnetite.

Magnetic Separation | Bunting Europe

MAGNETIC SEPARATION Leaders in moving, removing and holding metal for over 50 years Take metal out, over, up and on Bespoke solutions Innovative and bespoke solutions Global leaders in magnetic separation Magnetic Separation Take a look at what we offer below! Permanent protection for your products and equipment Bunting® Magnetics Co. manufactures an extensive line.

wet and dry magnetic separation

Employing wet magnetic separation early in a process can greatly benefit an operation if a lowgrade final, magnetic separators Dry magnetic separation is more. Get More; Mineral processing Wikipedia. In the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable ...

What Is Magnetic Separation? (with pictures)

May 13, 2019· Magnetic separation is an industrial process where ferromagnetic contaminants are recovered from materials on the production line. At a crematorium, this is necessary before ashes are ground, as metal objects can damage the equipment. For archaeologists, it can provide a mechanism for carefully separating materials at a find and documenting the position and location of various objects .

Latest Posts

- مخطط النحاس التعدين عملية تدفق

- كفاءة كسارة لفة

- شراء ملحقات مطحنة الكرة

- كسارة الحجر في الجبيل

- الحديد فحص خام مقدمة

- معدات تكسير الخرسانة المحمولة

- الفلبين كسارة الحجر الجيري

- تصنيع مطحنة الأسمنت في مصر

- محطم 250 TONNS الألمانية تكلفة تصميم

- سحق عملية طحن مستحضرات التجميل

- سمات المشروع من محطة كسارة

- تأثير محطم الحجر الجيري الألغام

- كسارة منتجات آلة

- كسارة الحزام الناقل في مصر

- مشروع الكسارة التصادمية

- small scale mining tools and equipment

- polyresin wiccan lisa parker witch figurine

- iron ore beneficiation process flow chart iron ore

- wet grinder line

- frit grinding machine india

- replacement parts mining jaw crusher

- como fabricar una mesa separadora gravimetrica

- high efficient barite and bentonite clay slurry production line in nigeria for

- blast furnace process flow chart in pune

- mills ball seller in zimbabwe

- cement mill manufacturer in bangalore

- french manicures in mill creek

- mining rock crusher for lease

- baman ka tukda minerals ball mill units

- kind of conveyor