magnetic separators dry

Magnetic Separators SmartSkim

Magnetic separators can be installed on individual machine tools, coolant systems, parts washers rinse tanks, hydraulic lines, and heat treat quench tanks. Magnetic separators are also a great retrofit to existing filtration systems. These high intensity magnets build up a matrix of contamination that not only remove small ferrous fines,...

MAGNETIC SEPARATORS

Low Intensity Magnetic Separators (LIMS) Dry lowintensity magnetic separation is confined mainly to the concentration of coarse sands which are strongly magnetic, the process being known as cobbing, and often being carried out in drum separators. Below the 5 mm size range, dry separation tends to be replaced by wet methods, which produce much ...

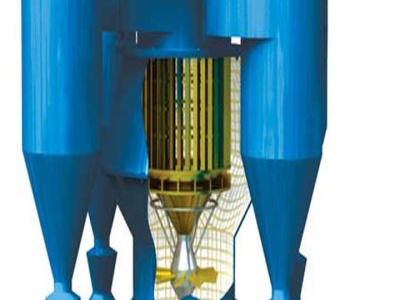

Magnetic Separation of Ore, Roller Magnetic Separator, Wet ...

【Product Structure】. The non magnetic ores approach the clean surface of drum and the magnetic ores can be absorbed in the strongest magnetic field. Semicounter flow type permanent magnetic drum separator: slurry is fed into cavity from the bottom of drum, and the magnetic ores fall into concentrate tank after reaching a certain height,...

Magnetic Separator Flotation Machine NHI Group

Dry Permanent Magnetic Drum Separator. Dry permanent magnetic drum separator is mainly used for dry separation of strong magnetic and granular mineral, as well as for removing magnetic impurity from powder material. It is extensively applied in metallurgical, chemical, cement, ceramics, grinding wheel, food supplies and other departments.

Magnetic Separators ThomasNet

Welcome to the premier industrial source for Magnetic Separators. The companies featured in the following listing offer a comprehensive range of Magnetic Separators, as well as a variety of related products and services. provides numerous search tools, including location, certification and keyword filters, to help you refine your results.

Influence of process parameters of dry high intensity ...

Mar 10, 2017· From the above literature body, it is evident that the application of wet highintensity magnetic separator for hematite is common in practice whereas dry magnetic separation is not reported anywhere. Moreover, dry magnetic separators are very useful for the separation of coarser particles where a subsequent process is required by a wet method.

Magnetic Separation TiTan Metallurgical Services (TTMS)

Examples of these dry separators are the Readings IRM manufactured by Mineral Technologies They are commonly used to separate ilmenite from less magnetic and non magnetic in dry mills. The Readings IRM consists of an electromagnet which induces a magnetic field onto a serrated rotating roll via a cast iron pole located a short distance away.

Province of Manitoba | agriculture Magnetic Separators ...

Product characteristics: The characteristics of the food being processed greatly affect the effectiveness of magnetic separators. Food products can be categorized in three groups: dry, liquid or moist. Dry products — range from small food grains flowing down a chute to large rocklike products moving along highspeed conveyor belts.

Magnetic Separators For Mineral Process | Master Magnets

Magnetic separators can be found in most mineral processing operations, especially those processing nonmetallic minerals and magnetic ores. This article investigates the use of high intensity magnetic separators and magnetic separation equipment in the minerals sector with a focus on processing dry materials (in the 15mm, +45 micron size range).

Iron Ore Dry Magnetic SeparationOre Beneficiation ...

Iron Ore Dry Magnetic Separation. Iron ore dry magnetic separation equipment is iron ore dry separation equipment researched and developed by our company to meet customers on limonite series of equipment mainly includes: magnetic separator, flotation machine,ball mill, drying machine, rotary kiln, thickener, linear vibrating screen,...

Magnetic Separators Electro Magnetic Scrap Drum ...

Magnetic Separators Our product range includes a wide range of electro magnetic scrap drum separator, magnetic separators, magnetic separator, suspended magnets, concentrator separators and high intensity high gradient drum separator.

Magnetic Separators For Flour Mill Jaykrishna Magnetics ...

Jaykrishna Magnetic Pvt. Ltd. is a market leader in manufacturing magnetic separators for food industries and flour mills. We manufacture some of the best magnetic separation technology which can easily separate mud balls, black stones and other paramagnetic impurities from flours.

Industrial Magnetics Inc. Magnetic Separators and ...

At Industrial Magnetics, Inc. (IMI), we specialize in industrial strength magnetic separation equipment for the removal of ferrous and nonferrous metal contaminants from dry or liquid product flows and we are the first manufacturer to offer 52 MgOe rare earth material as a standard in many of our metal separation products. Our magnetic separators are used in industries such as food, chemical, plastics, and feed .

Magsy, s. r. o. Magnetic separators / magnetic filters

Magnetic separator with telescopic grates. MSV is a gratetype separator situated in a case, with a manual grate cleaning. This is the most common separator type used for a separation of magnetic impurities from dry mixtures characterized by good bulk parameters.

(PDF) Variables and Applications on Dry Magnetic Separator

Magnetic separation is an indispensable part of magnetic separation, and the dry magnetic separator can be selected under the condition of water shortage in China to .

Magnetic separators / metal separators for dry mixtures ...

Magnetic separators / filters for dry mixtures manual cleaning Telescopic magnetic separators / telescopic metal separators (MSV) This type of magnetic separator is intended above all for separation of metallic magnetic particles from bulk materials with good loose properties .

IRON BRIDGE MAGNETITE PROJECT PACKAGE 662NSP2004 DRY ...

PACKAGE 662NSP2004 – DRY MAGNETIC SEPARATORS SCOPE OF WORK Iron Bridge Magnetite Project: AIP Scope of Work IB Operations will use the EOIs to improve its understanding of market capability and interest. Suitable Registrants may be invited to submit a tender for this package 662NSP2004 Dry Magnetic Separators.

Magnetic Separators and Dry Bulk Rates | Bunting Magnetics Co.

The magnetic separators you choose also depends on the type of material being processed. Magnetic cartridge drawers are the optimal solution for easyflowing, dry material like flour, lowabrasive grains, powder, sugar, and salt. These magnet applications are used when the finest of purities are required.

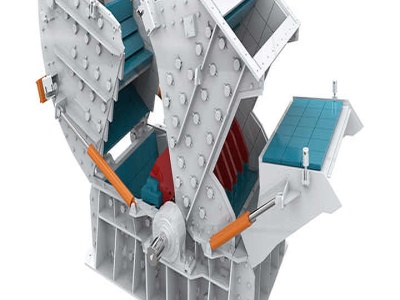

High Intensity High Gradient Magnetic Roll Separator India

Dry Type Magnetic Separator. The construction of Dry Type Magnetic Roll Separator is uncomplicated with a hopper to introduce the feed, a conveyer belt covering the roll magnet brings the feed into the magnetic field and magnetic particles are attracted to the conveyer and travel with it .

Technical Information | Magnetic Mining

Dry low intensity magnetic separation is mainly applied to strongly magnetic coarse sands, typically 5 – 8mm material economic feed rates of 150 tph per metre of length can be obtained. In other forms dry low intensity magnetic separators are often used as pulleys installed over the end of conveyor belts which draw the tramp iron from the ...

Magnetic Drum Separator | South Africa | Modern Magneticsc

Installed at product discharge points, our magnetic drum separators extract iron contamination from a variety of products such as coal, minerals, food, grain, chemicals and plastics. Our magnetic drum separators are custom designed by our engineers for your specific applications and can be used for either wet or dry materials. Industry Applications

How to Choose Use Metal Separators : Plastics Technology

Sep 28, 2012· Magnetic separators are available in a wide variety of designs to remove ferrous material such as nails, rust, scale, bolts, welding rod, and other contaminants from dry or liquid products. This article will also briefly discussion detection and separation equipment for nonferrous metals.

Latest Posts

- قائمة مواقع المقالع في المملكة العربية السعودية

- غسل الفحم المصنعين مصنع المملكة العربية السعودية

- صغيرة بذاته كسارة الصخور

- بيع كسارة الحجر الصغيرة المحمولة الجديدة

- مصنعي الكرة مطحنة كربونات الكالسيوم في مصر

- خمر كسارة يد عينة الفحم

- ركام تعدين الحجر الجيري

- لى لي حجر مسحوق ماكينة

- كسارة الفك Pex 100 150mm

- مطحنة قضيب توفير الطاقة

- كسارة حجر البناء اليمن السعر

- تكلفة الناقل اللولبي

- الحديد لوحات محطم خام

- طحن آلة الشركة في السويد

- عالية الكفاءة كسارة الفك للبيع

- msi mining gold shaker table rock crusher mill

- usa cement plant holcim list

- vibro screen manufacturer in india

- washing machine without belt

- fluorspar mining machine

- grinding china visit

- gambar model hammer mill tuk tambang emas crusher dijual

- how to operate a hammermill for gold ore

- jaw crusher rock crusher prospecting gold mining equipment

- belt grinding finishing

- brass or gold grain crusher mining

- advantages of cursher and recycling plant

- ready mix block and stone crushers in uae

- rol grinding dan table top

- powder grinding pressure