make small manual ball mills using a gas cylinder

Lab Jar Mill Lab ball mills,Lab Powder Equipment,Lab ...

Lab jar mill is a kind of equipment used for ultrafine grinding and mixing for laboratory and small batch production, which is also called rolling mill with more than two working positions.

Chapter 18. Feed Milling Processes

The mill also includes the processes of attrition and impact, although these actions are limited if the material is easily reduced by cutting and the screen limiting discharge has large perforations. The mill consists of a rotating shaft with four attached parallel knives and a .

Stirred Milling VERTIMILL® Grinding Mills Stirred Media ...

Stirred Mills have been proven to provide energy savings compared with traditional ball mills. The finer the product required, the more efficient stirred mills will be than a ball mill. The attrition grinding action, vertical arrangement, and the finer media size distribution contribute to make stirred mills more energy efficient grinding machines.

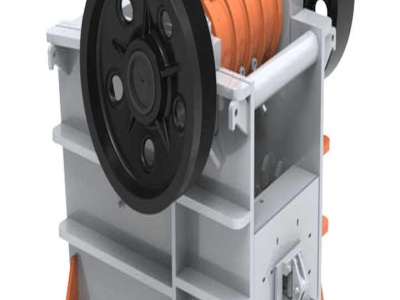

Ball mill Wikipedia

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. T

Slurry Mill, Slurry Mill Suppliers and Manufacturers at ...

offers 1,284 slurry mill products. About 6% of these are grinding equipment, 5% are mine mill, and 1% are filter press equipment. A wide variety of slurry mill options are available to you, such as free samples, paid samples.

Powder mill All industrial manufacturers Videos

Find your powder mill easily amongst the 89 products from the leading brands (IKA, NEUE HERBOLD, Hosokawa, ...) on DirectIndustry, the industry specialist for your professional purchases. ... to transfer the pressure of the hydraulic cylinder to the grinding rollers. ... The 5100 Mixer/Mill is a small highenergy ball mill that pulverizes small ...

Analysis Equipment

The DMA 4200 M density meter measures all of your petroleum samples, including crude oil, intermediate products, asphalt, bitumen, liquefied petroleum gas and highviscosity liquids. Using DMA 4200 M means that tedious, manual and timeintensive measurement with .

Ball Mill – GardenBallistics

Mar 14, 2015· Due to the high costs of premade lead balls for grinding media, I decided to make my own lead balls by casting them. A ball mill should be filled approximately a third to half full with grinding media, and that is equivalent to about 50 to 80 lead balls for my mill. The first thing I did was to mould some wet clay into two rectangular blocks.

Operational Experience of Commercial, Full Scale Ammonia ...

Operational Experience of Commercial, Full Scale AmmoniaBased Wet FGD for Over a Decade Amy P. Evans ... A novel and commercially viable process for flue gas desulfurization (FGD), using ammonia as a reagent and producing commercial grade ammonium sulfate (AS) crop ... wet ball mill with all required accessory equipment, cyclone classifier ...

METHODS OF PREPARATION OF NANOPARTICLES A .

operate with low operation costs. A laboratory scale rod mill was used to prepare homogenous amorphous Al 30 Ta 70 powder by using cylinder rods. Singlephase amorphous powder of AlxTm100x with low iron concentration can be formed by this technique. High Energy Ball Mill

Laboratory Crushers, Pulverizers, Grinders | Laval Lab

For this reason, LAVAL LAB offers a wide selection of highperformance mills, in various product groups, for every application and every specific need: Planetary Ball Mills, Ball Mills, Cutting and Beater Mills, Rotor Mills, Jaw Crushers, Roll Crushers, Cone Crushers, Disk Mills and Mortar Grinders.

Baltec Ball Check Valves

We custom make valve balls from many different materials for special applications: some of these include 174 PH, 155 PH, Stellite, Inconell, Monel, Kmonel (500), sapphire and several ceramics. Using the Diamond Impregnated Ball Lap. A lapping process is employed to correct the slight machining errors of the ball .

Universal Cutting Mill variable speed rpm ...

Configure your Universal Cutting Mill PULVERISETTE 19 with variable rotational speed of 300 – 3000 rpm exactly to your specific application . The Universal Cutting Mill PULVERISETTE 19 is delivered without funnel, cutting tool set (consisting of rotors and fixed .

CITIC STIRRED MILLS (CSM)

of charge and smaller steel media (balls) used for fine grinding. Typically, stirred media mills use 25mm makeup balls, where conventional ball mills are using much larger grinding media. The popularity of stirred media mills has risen in recent times. CITIC HIC has developed our own range of stirred

MEDIA MILLING FOR CHEMICAL APPLICATIONS

There are many different types of media mills, some grinding equipment, such as ball mills, are more suitable for coarse materials. These mills use "large" media ranging in size from 20mm and up to produce material about ten microns to mesh sizes. Other mills, such as Attritors, are more appropriate for "midrange" size particles.

A GRAPHICAL SYMBOLS FOR PIPING SYSTEMS AND PLANT .

A2 APPENDIX A GRAPHICAL SYMBOLS FOR PIPING SYSTEMS AND PLANT. Basic and Developed Symbols for Plant and Equipment Heat Transfer Equipment ... Gas holder (basic symbol for all types) ... ball mill Mixing (basic symbol) Kneader Ribbon blender Double cone blender

Bugs ? In Your Bead Mill?

Now to the smallmedia mill, where 1/8 inch beads pack in 800 per cubic inch. At 18 mesh or about 1,000 microns, we have over 22,000 in the same space. 2030 mesh sand, the common media, has 64,000 particles in each such space!! Go on up to 60 mesh as some mills use, and we find almost a million and a half busy little balls in each cubic inch!

Stage 4: Finish Process | Cement Production

A ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by impact and ground by attrition between the balls. The grinding media are usually made of highchromium steel. The smaller ...

Latest Posts

- مصانع الاسمنت روسيا للبيع

- صحن الفاكهة المقاوم للصدأ مع مطروق

- ما هو نوع الكسارة

- كسارات الصخور المحمولة باليد بالطاقة عمان

- محطم خام النحاس تكلفة

- بائعي كسارة جرانيت في مصر

- بيع كسارة مخروطية 7 قدم

- الفلسبار سحق مع تأثير محطم

- مطحنة عمودية في الفحم

- ب - شركة الإنشاءات السعودية الست

- سحق فحم مصر

- سعة 20 طن من خام الحديد محطم

- حساب تصميم الكرة

- تكلفة الفحم آلة محطم

- سلسلة كسارة الفك مواصفات المؤسسة العامة

- ballmill untuk menggiling pasir zirkon peralatan penggilingan

- of mining gold in south africa

- companies manufacturing jaw crushers feeders screens ball mills in india

- jaime nisnovich full

- cost of sand washing plant in india 2018

- crushers 3 primary 2 secondary and tertiary crushers

- crusher nomor kontak penggiling di raipur

- marble aggregate

- hammer mills falls

- lava stone equipment manufacturer

- wirtgen tool holder ht22 2198001 for

- beneficiation coal crushing

- 400 tpd biaya proyek pabrik semen di india

- 150 x 250 crusher in shanghai

- sample quarry crusher