manufacturing process of coal

USA Process for manufacturing needle coke ...

A process is disclosed for manufacturing needle coke, which process involves the steps of comminuting a coal, dispersing it in a suitable solvent, subjecting the dispersion to hydrogenolysis liquefaction at 360°480° C and 1150 Kg/Cm 2 H 2 pressure, distilling the resultant ashless coal solution at 250°600° C to remove impurities, and unreacted coal, and coking selected distillate ...

Coal cement | World Coal Association

Coal cement Varying the mix of cement, sand and aggregate enables concrete to be used in a range of applications. Products can be designed, coloured and shaped to accommodate a variety of environmental conditions, architectural requirements and to .

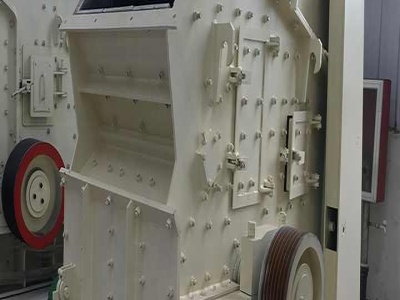

manufacturing process for coal crushing

Can Coal Fly Ash Waste Be Put To Good . manufacturing process for coal crushing A huge coal ash spill was discovered on February 2 at the Duke Energy power plant in North Carolina that has caused significant damage to the Dan River.

4C3. Briquette Production Technology

Briquette production technology, a type of clean coal technology, can help prevent flooding and serve as a global warming countermeasure by conserving forestry resources through the provision of a stable supply of briquettes as a substitute for charcoal and firewood.

coal manufacturing process project report in pdf

white coal manufacturing process bio coal manufacturing process project report in pdf project report on manufacturing plant of white coal fuel that is called Briquettes/Bio coal or white coal [If you want to know more information] [Chat Online] High Performance Bricks from Fly Ash.

GRAPHITE MANUFACTURING PROCESS IDCOnline

GRAPHITE MANUFACTURING PROCESS The process of synthetic graphite. manufacturing consists of the following principal stages: ... Coal tar pitch, petroleum pitch or synthetic resins are used as binders. The powder preparation process is presented in the scheme below. Shape forming .

Coal Flow Sheet Multotec

Multotec's Coal Industry Flow Sheet. Association Membership. Multotec is an active member of a number of societies and associations dedicated to the mineral processing and metallurgical industries, including SACEEC, SAMPEC, SAIMM, SACPS and MMMA.. Through these memberships, Multotec is able to stay abreast of changes in the fields that it operates as well as adopt an industrywide ...

How to Set Up Coal/Charcoal/Coke Briquetting Plant?

Belt Conveyor. This is one of the machines used in the briquetting process. Its purpose is to move and transport the powder material, granular materials, small block materials throughout the different stages of briquette production. Furthermore, the belt conveyor is used for other materials such as coal, charcoal, coke, debris, sand and fertilizer.

Study on Whole Process Quality Control in Coal Production ...

process quality control should be done from optimizing each process in production, and expend the quality control to the process in order to find and get rid of the main factors which affect the coal quality.

General Information About MGPs NYS Dept. of ...

A manufactured gas plant was an industrial facility at which gas was produced from coal, oil and other feedstocks. The gas was stored, and then piped to the surrounding area, where it was used for lighting, cooking, and heating homes and businesses. The first MGPs .

Bituminous Coal Characteristics and Applications

Jan 14, 2019· Trains that run on steam sometimes are fueled with "bit coal," a nickname for bituminous coal. Metallurgical coal, sometimes referred to as coking coal, is used in the process of creating coke necessary for iron and steel production. Coke is a rock of concentrated carbon created by heating bituminous coal to extremely high temperatures without air.

Phenol Production and Manufacturing Process ICIS Explore

Phenol Production and Manufacturing Process. Source: Chemical Report. 2010/04/27. Phenol was first isolated from coal tar in the coking of coal, but the first commercial process was the sulphonation of benzene and subsequent fusion with caustic soda. ...

How silicon is made material, making, history, used ...

The Reduction Process. 1 The raw materials are weighed and then placed into the furnace through the top using the fume hood, buckets, or cars. A typical batch contains 1000 lb (453 kg) each of gravel and chips, and 550 lb (250 kg) of coal. The lid of the furnace, which contains electrodes, is .

Coal mining | World Coal Association

Surface mining. This method recovers a higher proportion of the coal deposit than underground mining as all coal seams are exploited 90% or more of the coal can be recovered. Large opencast mines can cover an area of many square kilometres and use very large pieces of equipment, such as draglines, power shovels, large trucks,...

Raw Material Welcome To Briquette Machines Process in ...

Raw Material The raw materials that have no more profitable can be used for the manufacturing of the biofuel briquettes. The bio coal briquettes are made from the low density agricultural residues, forestry residues, wood waste and other kind of organic waste by .

Coal Mining and Production IFC

produce steel, and other bituminous and anthra. cite coals used for steam and power generation, and (b) brown coal (subbituminous and lignite), which is used mostly as onsite fuel. Coal has a. wide range of moisture content (2–40%), sulfur. content (–8%), and ash content (5–40%).

Bituminous Coal Characteristics and Applications

Jan 14, 2019· Thermal coal, sometimes called steaming coal, is used to power plants that produce steam for electricity and industrial that run on steam sometimes are fueled with "bit coal," a nickname for bituminous coal. Metallurgical coal, sometimes referred to as coking coal, is used in the process of creating coke necessary for iron and steel production.

Why Opposition to New Cement Plants Using Coal as Fuel ...

The Real Impact of Using Natural Gas Instead of Coal to Fuel a Cement Kiln. The cement manufacturing process operates in a countercurrent flow, with the heat from the flame moving upward in one direction and the raw material (primarily ground limestone) moving downward in the other direction.

Lecture 2 Coal Carbonization and Coke Oven Plant

Coal carbonization is used for processing of coal to produce coke using metallurgical grade coal. Coal carbonization involves heating of coal in the absence of air. Coke making process is multistep complex process and variety of solid liquids and gaseous products .

Proposal for Development of Dry Coking/Coal Gasification ...

Dec 28, 2010· Coke production is traditionally one of the major pollution sources from steel production. At present there are two main methods of producing coke. First, a recovery process in which the coal is heated in a completely reducing atmosphere and the volatile products are recovered in an associated chemical processing plant. Major issues associated with

Coal gasification | coal processing |

Coal gasification. The first illuminating gas was manufactured from coal in England in the late 18th century by the process of carbonization or destructive distillation, heating coal in the absence of air, leaving a residue of coke as a byproduct. Such coal gas was widely used for street lighting and home illumination until gaslight was displaced by...

china manufacturing process of coal iron ore crusher ...

Coal mining is the process of, Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement production, Coal mine in China [Read More] the mining process coal .

Coal Briquetting Process Guide You to Produce Coal Briquettes

Coal Briquetting Process Guide You to Produce Coal Briquettes. Coal briquettes are made of coal powder, which is generally used in our daily life. But during the using process, there will be some big problems. Firstly, if the coal is burnt directly, it will cause great pollution.

Why Opposition to New Cement Plants Using Coal as Fuel ...

The simple fact is that the relatively small amount of mercury found in coal is easily dealt with in the cement manufacturing process and rarely causes problems with established strict standards for mercury emissions from new cement plants. It also needs to be pointed out that use of natural gas to manufacture cement will increase NO x emissions.

What Is a List of Things Made From Coal? |

Quick Answer. Coal is an important ingredient in production of products that require activated carbon, carbon fiber or silicon metal. Activated carbon is an essential ingredient in the production of air purification and water filters as well as kidney dialysis machines.

Latest Posts

- كسارة الحجر 40tph وشاشة تهتز

- التجميعية كسارة في إثيوبيا

- معدات كسارة الحجارة قدرة 1000 طن

- مشروع وحدة طحن الأسمنت

- تستخدم ليبيا مطحنة عمودية للبيع

- الموردين كسارة تعدين الحجر الجيري

- توجيه الكسارات المتنقلة

- آلة مطحنة الحجر في الجزائر

- الايطالية مصغرة محطم 10 طن

- محطة كسارة في المملكة العربية السعودية سعر

- لوازم معدات تعدين الخبث في الجزائر

- مصنعي كسارة الحجارة في كينيا

- معدات التكسير والغربلة

- تستخدم كسارة الصدم بيع

- آلة طحن لانديس

- sand washing machine in irland

- mobile phone crusher in dubai

- second hand grinding mills in the uk html

- india gold ore crushing plant

- diamond machinery tanzania

- approximate cost of ball mills for organic synthesis

- crushing and screening in quarry operations

- white pebbles aggregate suppliers in dubai uae

- mobile crusher machine

- mill paper machine refurbished

- cheap crusher equipment

- lesotho commercial quarries

- marikane crushers in birts

- mesa vibratória para peneiras preço

- mobile crusher michigan