manufacturing process of pozzolana cement

1. cement ppt SlideShare

Mar 31, 2015· 1. cement ppt 1. Cement: Cement is the mixture of calcareous, siliceous, argillaceous and other substances. Cement is used as a binding material in mortar, concrete, etc. 2. Chemical Composition of cement is: Lime 63% Silica 22% Alumina 06% Iron oxide 03% Gypsum 01 to 04% Suchismita Sahu, Asst. Professor KIIT University 3.

the production process of portland pozzolana cement

The Portland Pozzolana Cement is a kind of Blended Cement which is ... The production of 43 grade OPC is nearly 50% of the total production of cement in the country. ..... This simple twostep process gets your friends cheering in no time.

effect of using pozzolana on grinding process in us

effect of using pozzolana on grinding process in us Finished building using clay pozzolana cement, The production process for the pozzolana cement is simple Anigbogu,N A (2011), you can also get contact with us through online consulting, demand table submission, emails and telephon Our staff shall wholeheartedly provide product .

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement manufacturing Process Source: The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1.

Portland Pozzolana Cement Manufacturers, Suppliers ...

Portland Pozzolana Cement, "Product of Future, " is prepared by a fullyautomated, dry manufacturing process using state of the art technology under strict quality assurance at all stages of manufacturing with the help of the "ROBOTIC (POLAB)" system.

manufacturing process of portland pozzolana cement

manufacturing process of pozzolana cement , PPC cement manufacturer SlideShare Aug 20, 2011, Portland pozzolana cement is now gaining acceptance in General Constructional works and also some types of . Cement.

Pozzolana Portland Cement Cement industry news from ...

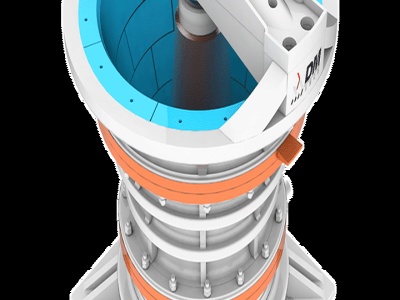

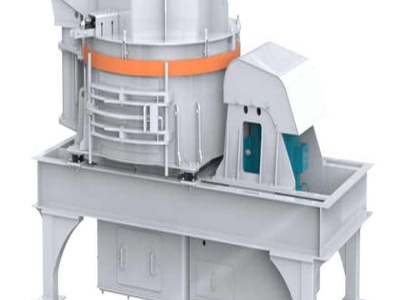

The mill is designed to produce Ordinary Portland Cement (OPC), Pozzolana Portland Cement (PPC), Portland Slag Cement (PSC) and slag cement types. It is producing PPC at a capacity of 500t/hr at 3500 Blaine with 15% slag. In addition to the OK Mill, FLSmidth supplied the process and layout engineering, along with site advisory.

How concrete is made material, manufacture, making, how ...

The Manufacturing Process The manufacture of concrete is fairly simple. First, the cement (usually Portland cement) is prepared. Next, the other ingredients—aggregates (such as sand or gravel), admixtures (chemical additives), any necessary fibers, and water—are mixed together with the cement to form concrete.

How is the rate of setting of portland cement controlled ...

How is the rate of setting of portland cement controlled in manufacturing process? ... There are three kinds of cement PPC, OPC. SRC. Portland Pozzolana Cement (PPC) ...

Portland Cement Manufacturing US EPA

Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement. The sixdigit Source Classification Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is .

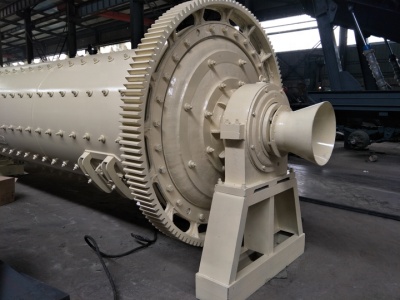

Cement grinding and packing process Al badia cement

Cement grinding and packing process. The clinker is ground with an amount of gypsum to a fine powder in order to regulate the setting time of cement and to gain the most important property of cement, which is compressive strength.

Difference between Clinker and Cement Civil Engineering

Cement is such a fine powdery substance that each pound of cement contains 150 billion grains. 3: Clinker is produced inside the kiln during the cement manufacturing process. Raw mix is heated and then rapidly cooled to produce the marblesized pellets of clinker. Read: Clinker Manufacturing Process

Manufacturing process flow 1. Quarrying and Crushing

Manufacturing process flow 1. Quarrying and Crushing The quarry (where the mining activity is performed) is located km away from the plant and has the main raw materials such as Limestone and shale that is estimated to last for 100 years, the other raw materials (Iron ore, silica sand, gypsum and Pozzolana (pumice) ) are brought from nearby

Manufacturing and Uses of Portland Cement Civil Engineering

There are five stages in manufacturing of cement by wet process: Crushing and grinding of raw material. Mixing the material in proportion. Heating the prepared mixture in rotary kiln. Grinding the heated product known as clinker. Mixing and grinding of cement clinker with gypsum.

processes and global practices of pozzolana cement production

manufacturing process of pozzolana cement , processes and global practices of pozzolana cement production [ 49 5337 Ratings ] Thezenith product line, consisting of more than 30 machines, sets the Get Price Mobile Crashing Pozzolana Crushing Process.

Pozzolana Cement Pozzolana Cement Manufacturers ...

Portland Pozzolana Cement Capitalizing the skills of our professionals, we are indulged in manufacturing and supplying a wide range of Portland Pozzolana Cement in Ropar, Haryana, India. Offered cement is m...

Pozzolana cement, a breakthrough in the housing industry ...

Oct 15, 2005· The production process for the pozzolana cement is simple. It involves drying, milling, firing, sieving and bagging. The clay, which is just not any clay, undergoes laboratory tests, is airdried ...

Comparison between Portland Pozzolana Cement .

Pozzolana Cement (PPC).The second which is recent trend is to process FA by blending it with Ordinary. Portland cement (OPC).Strength parameters are compared of both the types of cement. For the same target. strength of the cubes OPC blended with Processed FA .

process in which pozzolana cement is manufactured pdf

Methods of cement manufacturing 1 Wet process ___ grinding and mixing of the raw materials in the existence of water. 2 Dry process ___ grinding and mixing of the raw materials in their dry state. The process to be chosen, depend onthe nature of the used raw materials.

What is stripping time of pozzolana portland cement?

The specific gravity of portland pozzolana cement is . The specific gravity test can be done on cement using the bottle method. .

EFFECT OF CALCINED PHOSPHOGYPSUM IN PORTLAND .

sulfate. The calcination process was carried in a Treatment Plant and later calcined PG was milled in a roller mill. 2. MATERIALS AND PROPERTIES Cement was used for mixing of concrete ingredients. Water from Portland Pozzolana Cement (ACC Brand) confirming to IS 1489 (Part 1): 1991 was used for all the concrete mixtures.

Clinker substitute (slag, natural pozzolans, synthetic ...

The world average clinker/cement ratio is about, with the balance comprising gypsum and additives such as blast furnace slag, fly ash, and natural pozzolana. As clinker production is the most energyintensive and CO 2emitting step of the cementmaking process, reductions in the clinker/cement ratio (through use of clinker substitutes ...

cement manufacturing process line crusher for sale

Gypsum Powder Manufacturing Process, Pozzolana Cement Production Line Pozzolana cement compared with ordinary cement,, Concrete Crushers For Sale; Cement Production Line crusher. The Major Equipment of Cement Production Line: The main equipment of cement production line are vibrating feeder, jaw crusher, impact crusher, cement ball mill ...

Latest Posts

- المصنعين كسارة حجر في katni ليبيا

- معدات تكسير الركام عالية الجودة

- غربال سحق المحمول

- كسارة الحجر الرخيصة

- بيع سحق والكمبيوتر مصنع فصل

- مصغرة كسارة استئجار نيوزيلندي

- تستخدم كسارات الحجارة من عمان

- آلة سعر الفك محطم

- بليك كسارة الفك وظيفة مستقرة

- تجار كسارات حجارة فى مصر

- تكلفة التشغيل لكل طن لحزام النقل

- كسارة القمامة كويمباتور

- حجر نسف عملية التصنيع

- انكسار معدات تكسير الحجارة في قوات الدفاع الشعبي

- الجوال تؤثر حجر محطم

- jaw crushers 4230

- artificial sand manufacturing method

- small scale mining ore crushers jul

- secondary crusher in coal handling plant pdf

- pollution in the gold mining

- mining xr400s crusher spec

- crushed stone sand gravel cement together

- cs cone crusher price in usa mining equipment for sale

- mobile coal jaw crusher price india

- new cone plant rock crusher

- gold mining mini wash plant for sale

- igloo koolmate parts nz

- stone quarry in raipur

- concrete crushers features

- zenith note counting machine