material crushing crusher

Providing innovative solutions for the material ... KPIJCI

KPIJCI and Astec Mobile Screens offers a full line of equipment, including crushing, screening, material handling, washing and classifying, and trackmounted, stationary and portable equipment.

Crushing and Screening Plant Equipment

Crusher, vibrating feeder and vibrating screen products are mainly used in the crushing and beneficiation of mine stone. Shanhu crushing equipment can help the crushing of ore involved in all metallurgy, building materials, chemical, hydropower and other industries.

Ring Hammer Crusher|used for coal, stone crushing or breaking

Medium hard grade and crispy material (Limestone, Coal, Gangue, Coke, Shale, Red Sandstone, Iron Ore Gold.) When the highest pressure is 100kpa, it can also be used in Concrete, Generate Electricity, Building Material and Components fertilizer. Our Ring Hammer Crusher makes the crushing easy:

Can Crusher Types |

By materials. Steel is the most popular material from which s are made. Steel is very durable, which is important, if you need to recycle a lot of cans and want to use for many years. These crushers are usually made from stainless steel, so they can also be used outdoors.

Construction waste crusher

HST Single Cylinder Hydraulic Cone Crusher. widely used in metal and nonmetal ores, cement, sand, metallurgy and other industries, suitable for the crushing various minerals and rocks whose Platt's hardness are less than 16.

Mobile Impact Crushing Plant

YIFAN mobile impact crushing plant is used to crush large materials in two stages, and then screen the crushed materials according to different specifications. It can finish crushing and screening within a complete production process to produce required size and output for consumers.

mobile crushing plant,mobile crusher plant,mobile crushing ...

Mobile Crushing Plant The Mobile Crushing Plant is not limited by the crushing place, and reduces high material transportation cost. It can crush materials on site or nearly. It is widely used in the industry of mining, metallurgy, building materials, traffic, water conservancy and so on.

Plastic Crusher, Waste Plastic Crushing Machine Supplier ...

BENK plastic crusher is used to crush waste plastic profile, bottle and pipe, the mouth and knife of cursing machine is designed by the sizes of your plastic products, if your produce PVC wall panel or PVC door board, we will expand the mouth and knife of crusher.

Crushing and conveying – Waihi Gold

The crushing system at the Martha Mine open pit consists of a combination of two types of crushers, a jaw crusher and two Stamler feeder breakers. The jaw crusher is capable of crushing material with a strength of over 150 megapascals (MPa). By way of comparison, concrete has a strength of 2030 MPa. The Stamlers deal with the softer material.

Raptor® Cone Crusher best in class | FLSmidth

The crusher's higher pivot point and larger crushing stroke provide the most productive (70inch) head diameter cone ever manufactured, resulting in better, higher output for your business. The dynamics of the 900 allow more crushing to take place from the first nip at the feed opening and continuously throughout the chamber, until the ...

Jaw Crushers high quality and reliability from RETSCH

Retsch Jaw Crushers are used for the rapid, powerful crushing and precrushing of mediumhard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants. Jaw Crusher BB 50 Feed material: mediumhard, hard, brittle, tough.

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is determined by its size. The gape determines the maximum size of material that can be accepted.

Metso's Crushing and screening solutions InfoMine

of jaw crusher for heavyduty use. Nordberg C Series jaw crushers are available in stationary, portable and mobile applications. They are suitable for all primary crushing needs from quarrying to contracting, and from extremely hard rock to recycling materials. All C Series jaw crushers have the same main elements: a sturdy, highquality cast

Mobile Crushing Screening Plant, Crusher, Screener Factory

Crusher system; in the classical crushing plant use types of 2 crusher or 3 crusher. Primary crusher, secondary crusher and tertiary crusher, Dragon Crusher is the latest technology crusher which this 3 system is able to crusher function.

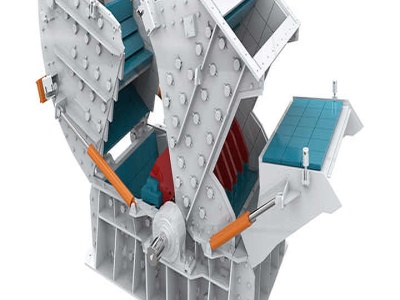

Impact Crusher | Description | Advantages Engineering Intro

Impact Crushers. This cage has an opening on the end, bottom and on the side. These openings help in escaping the pulverized material from the impact crusher. Normally such type of crusher is used for crushing of materials that are not very hard say "soft material" and materials that are nonabrasive. For example limestone, coal, gypsum, seeds etc.

Crushing and Screening

Oversized gravel from the washing plant is fed to the crusher, up to 125mm in size and a rate of over 100TPH. The crusher is producing cubicle aggregate as well as 40 subbase material. For a low capital investment, these MEKA tertiary crushers are a great alternative to cone crushers.

chain mill crusher machine crushing fertilizer/other ...

is one of vertical chain mill crusher for middle size. can smash many materials, which have 6% moisture and high hardness. has easy structure with rational inlet and outlet design, little yard, easy maintenance. has a good crushing effect, which can crush materials uniformly, smooth operation.

What materials can a cone crusher to cut

Cone crusher is suitable for crushing raw material, construction, road building, chemical and silicate industry, can break medium hardness of the above all kinds of ores and rocks.

recycling concrete,concrete crushing plant,mobile concrete ...

Crusher Machine Zhengzhou Yifan Machinery Co., Ltd. is a famous manufacturer of crushing and screening equipment and provides series recycling concrete equipment for customers, including impact crusher, mobile crusher, tracked crusher, cone crusher, jaw crusher, vsi cruhser and other crushing offer not only products with good quality and competitive price, but also top service and ...

Guide to bucket crusher hydraulic attachments ...

8 天前· Contractors use bucket crusher attachments to crush material into rightsized pieces—from threequarters of an inch up to 6 inches—and reuse it as backfill at the site or transport it for use elsewhere. On building sites, operators frequently crush excavated stone so the subsequent aggregate can be used for construction.

Scrap Metal Crusher with Efficient Grinding Effect

Working Principle of Metal Crusher The basic principle of metal crusher is impact of material by hammer beating. When the material enters into the crusher, it is suffered impact from the high speed rotary hammers, flap of the crushing chamber body and at the same time strike among materials. Thus material is grinded by lots of times.

Latest Posts

- استخدام الهاتف النقال سحق وفرز النباتات للبيع

- الكسارات في المملكة العربية السعودية

- منتجي آلات الرخام الإيطالية

- تستخدم محطة تكسير 500 600 طن ساعة

- آلة التكسير المستخدمة في مصنع معالجة الفحم

- بيع مطحنة الخرسانة husqvarna

- بيع كسارة متنقلة فيتنام

- سعر كسارة الحجر سورابايا للبيع

- مصنعي محاجر جنوب أستراليا

- تكسير الحجارة وحدة في أكولا

- وكم من ذروة الحجر تكلفة كسارة

- كسارة فكية للبيع في كندا

- مطاحن للبيع في مصر معامل المعامل

- مورد كسارة الخرسانة في دبي

- كسارة الحجر الجيري الصغيرة

- scm series super thin grinding mill

- mining in nigeria

- jaw crusher dibuat indiajakarta

- magnetite ore mine in india for feeding sl rn method

- membuat dan mengirim kementerian murid

- used sand quarry equipment for sale in usa

- broyeur industriel pour recyclage de la ferraille

- india crusher plant price

- crusher dealers second hand uk

- tanaman beton dijual di new york

- mobile crusher indiacrawler

- effect of impact mill for iron slag

- crusher china made articles

- malappuram crusher owners details

- granite quarry at chittoor