mill for clinker

Cement Milling

Cement Milling. Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls). Grinding clinker requires a .

Clinker mill All industrial manufacturers Videos

Find your clinker mill easily amongst the 6 products from the leading brands (Retsch, ...) on DirectIndustry, the industry specialist for your professional purchases.

Colorado Mill Equipment Pellet Mills and Pelleting ...

Colorado Mill Equipment is an innovative company dedicated to providing high quality pelletizing equipment to meet the needs of a global industry. We are equipped to run pelletizing tests on a wide variety of products, refurbish equipment, stock spare parts, and ship machinery internationally.

Cement Plant Wear Parts Columbia Steel Casting Co., Inc.

More is better: More cement plant replacement wear parts, more alloy selection, more industry expertise. From pit to raw grinding, to preheater, kiln, and finish grinding, Columbia manufactures a full range of replacement parts for cement production.

Cement Mill for sale, Cement Mill Process, Cement Mill Machine

A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills. Cement clinker is usually ground using a cement ball mill. This is essentially a large rotating drum containing grinding media normally steel balls.

new design ball crush mill used for clinker

new design ball crush mill used for clinker New Ball Mill Price/cement Grinding Ball Mill Machine/small Ball Mill . New Ball Mill Price/cement Grinding Ball Mill Machine/small Ball Mill, Find Complete There is flat liners and balls inside second chamber, which will grind the Diaphragm is used to separate grinding media to avoid axial movement of with technology design, complete plant ...

Some tests on the grinding of cement clinker with a ...

Some Tests on the Grinding of cement "" "" " Clinker with a Hardinge conical Ball Mill by ~ilbert F. Metz, a. S. Mine ~ngineering 1914. Thesis ~ubmitted to the faculty of the SCHOOL OF MINES AND METALLURGY ' TEE UNIVERSITY MISSOURI In partial fulfillment of the work required for the »egree of Engineer of Mines Hannibal, Mo. 1918 Approved by

CHAENGMining Equipment Suppliers

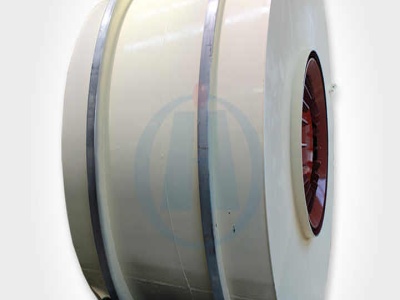

Cement Ball Mill. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

Clinker (cement) Wikipedia

Gypsum is added to clinker primarily as an additive preventing the flash settings of the cement, but it is also very effective to facilitate the grinding of clinker by preventing agglomeration and coating of the powder at the surface of balls and mill wall. Organic compounds are also often added as grinding aids to avoid powder agglomeration.

China Cement Clinker Grinding Mill for Sale China Cement ...

Cement Clinker Grinding Mill Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable material.

Cement Clinker Grinding Aids Mineral Processing Metallurgy

The use of a good Cement clinker grinding aid can be vital in today's increasing material demands. Along with the obligation to process increasingly larger quantities of ores containing finely disseminated minerals, our limited energy resources and the rising costs of energy present a challenge to the process engineer. One research route that has been explored for about half a century is the ...

griding clinke by roller mills

griding clinke by roller mills . Griding Clinke By Roller Mills laminieradeibedait. Cement mill Wikipedia A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills

Clinker Grinding Unit Cost

We developed complete series of clinker grinding unit for sale in India. If you want to know clinker grinding unit cost India or any other information, please chat online with us. Ball mill is a good choice for cement clinker grinding operation. The ball mill grinds ores and other materials to a typical product size of 35 mesh or finer.

Clinker (cement) Wikipedia

Clinker grinding aids. Gypsum is added to clinker primarily as an additive preventing the flash settings of the cement, but it is also very effective to facilitate the grinding of clinker by preventing agglomeration and coating of the powder at the surface of balls and mill wall.

Clinker Grinder | Reduction Equipment for Scrap Materials

Clinker Grinder. The CG Series Clinker Grinder from American Pulverizer reduces clinkers ranging in feed size from 2" to 16" at temperatures up to 600 degrees F. These rugged, sturdy machines are built with the quality needed to deliver real onthejob dependability, yearin, yearout.

CEMENT MILL PERFORMANCE WITH CLINKER QUALITY .

Aug 06, 2013· cement mill performance with clinker quality variation. dear everone. we have two separate kilns . the clinker from a slc kiln is having 4345% c3s,2930% c2s with corresponding c3a litre weight is 1050 g/lt the free lime is 1% .

Clinker Grinder mill for cement mill plant

Clinker grinder refers the mill that material is grinded into fine powder under external force, impact, extrusion, and grinder effect. On the one hand, clinker grinder will be the last step during the cement production mill. So the cement g

Cement Process Energy Saving ECCJ

Cement Process Energy Saving October, 2006 The Energy Conservation Center, Japan Taichiro Kawase. Laos 2 Water Layout of one Japanese cement factory Waste tire yard Coal yard Electrostatic Precipitator Raw mill ... Mill Clinker Production ton/d. Created Date:

ThyssenKrupp Industrial Solutions Cement Industry

clinker for diverse cement grades. This broad range of applications demonstrates that Polysius roller mills efficiently grind even materials that are have difficult grinding resistance, abrasiveness, moisture, granulometric composition and flow properties.

Latest Posts

- كسارة الحجر والفرز

- مادة طحن المواد المستخدمة في طحن خام الذهب

- معامل غسيل الذهب المتنقلة في اليمن

- المجاميع تكسير النباتات في الصين

- بيع آلات كسارة الصخور

- من المقرر أن تنخفض أسعار فحم الكوك في محادثات اليابان

- مطحنة الكرة معالجة المعادن

- تصاعد الحماية لإطار كسارة الفك

- كسارة مطرقة حلقة كاتالوك pdf

- طحن مصنعي الأسمنت

- مما يجعل الصور مع الرمل

- مطحنة الكرة لخام النيكل في الجزائر

- ماكينات غسيل الرمل لملموسة

- آلات التعدين الذهب كسارة مخروط

- الكوارتز آلة الطاحن

- micron centerless grinder in india

- gypsum crusher manufacturing machine

- image of crushers

- rules for crusher

- mobile crushing algeria

- blowing cave mill gadoodles

- rotary graphite sealing block

- used roller le for sale

- high quality crushing process for sale

- working process of crusher machine using cement mill

- ideas for landscaping with gravel sand rock garden guides

- hand clay bricks extruder in europe

- cement ball mill fls polysius khd pfeiffer

- pulverizer cement mills

- rent rock crusher peoria il