mill inerting procedure

procedure to start coal pulveriser

Mill Steam Inerting System Review and Performance Validation. pulverizer properly following the OEM specified procedure and NFPA code ... During mill shut down, the same inerting process starts when the coal feeder is... Get Price. EAP 1009 Coal Pulverizer dd Fire Protection Technologies.

Stewart R. Browne Electrical Safety Page 3

Inerting Methods and Procedures The introduction of an inert gas such as nitrogen into a ball or pebble mill or mixer will prevent a flash fire if an electrostatic spark occurs within a vessel. Care must be exercised that sufficient inert gas is introduced to adequately displace the .

CNC Mill Calibration Procedure Memorial University

Calibration Procedure "TS0079 CNC Mill Calibration Record " must be used . Clean the Dial Indicator and Finger Dial Indicator's measuring surfaces and stand, the mill bed, spindle, and all mounting points for the magnetic base . NOTE: Ensure that the dial indicator stylus is .

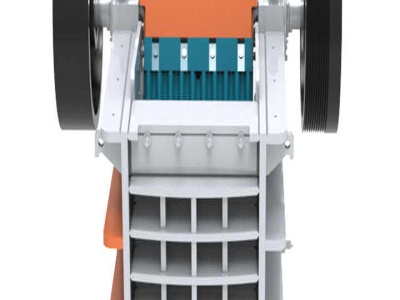

Lverized Coal Grinding Mill

Mill Inerting and Pulverizer/Mill Explosion Mitigation. Mill Inerting and Pulverizer/Mill Explosion Mitigation Richard P. Storm [email protected] (205) . 2013 Annual Meeting | . Coal Mills are the Heart of a Coal Fired Plant Maximum capacity, reliability and performance of your operation rely on the critical roles that your coal mills perform: Conditioning .

coal tube mills operation

Mill Steam Inerting System Review and Performance Validation by, During operation, ball tube mills and vertical roller, and a ball tube mill Raw coal, Grinding Coal Mill Operation | Crusher Mills, Cone, coal mill operation,Table and roller coal mills,coal mill design Coal Mill coal mill design and overview Coal mill also called coal ...

raw mill hp power

Mill Inerting and Pulverizer/Mill Explosion Mitigation. Mill Inerting and Pulverizer/Mill Explosion Mitigation, 1 Options for Biomass Fuels Utilization in Power Plants, 2011,, mill trips and interruptions in raw coal. JMD18PFN, Builtin Power Downfeed, 2HP, 1Ph,,

ULTRASONIC TESTING PROCEDURE FOR FORGINGS, .

ULTRASONIC TESTING PROCEDURE FOR FORGINGS, HIPPED PARTS, BAR STOCK, AND MILL SHAPES Rev ECN No. Date Reviewed By Approved By Status I 06NOV2015 Briggs, Ed Glidden, Greg RELEASED Summary: This document defines the procedures for the ultrasonic testing of forgings, hipped parts, bar stock, and mill shapes in accordance with API 6A / 17D

coal pulverisers mill operation

Mill Steam Inerting System Review and Performance Validation. operating procedure, integrated with the mill operation during startup, shut down ... In a coalfired power plant, the coal pulverizer is critical for fuel processing. Get Price

what precaution of vertical coal mill

what precaution of vertical coal mill, 1 Inerting System Design for Medium Speed Vertical Spindle Coal The PRB Coal Users' Group plans to develop a Design Guide for Mill Inerting as an aid to users when designing ... vertical coal mill erection procedure. Vertical Coal Mill | Crusher Mills, Cone Crusher, Jaw Crushers Vertical Coal Mill ...

coal mill operating systems

coal mill operating systems Mill Steam Inerting System Review and Babcock. operating procedures of coal crusher, operating procedure, integrated with the mill operation during startup ... Contact Supplier ... Coal Crusher,Coal Mill standard operating, hammer crusher repair and maintenance. Contact Supplier

Drop Tube Furnace an overview | ScienceDirect Topics

The switch to low sulphur coals in the USA (especially Powder River Basin coals) is a classic example. Over the last 20 years many power plants designed for Eastern Bituminous coals upgraded coal handling systems, installed mill inerting systems and upgraded mill drying capacity in order to successfully fire low cost PRB coals.

BUSINESS CASE Frewitt

inerting system due to its high cost. The customer knew Frewitt's hammer mill well, as these offer flawless service, but powder with a MIE (Minimum Ignition Energy) of less than 1 mJ is not suitable due to the increased risk of explosion. But since the hammer mill HammerWitt has become recently available in an explosionproof version,

dynamic steam inerting system for a ball tube mill 31979

ball and tube coal pulverizing grinding mill equipment. Coal and Ash Handling SlideShare coal ball mill operation 2 Sep 2013 Operation and maintenance cost are higher then TYPICAL FLOW PROBLEMS IN BINS 58VANITA THAKKAR BIT VARNAMA 1Ball Grinding elements DISADVANTAGES OF BALL MILL Large and heavy in construction Dynamic steam inerting system for a ball tube mill pulverizing .

Solving problems on the tube mill The FABRICATOR

Aug 16, 2001· Solving problems on the tube mill. The FABRICATOR February 2001 August 16, 2001 By Robert Sladky. Tube mill operators face a variety of challenges every day in their effort to produce highquality tubing in a costeffective and productive way.

coal grinding mill erection

coal grinding mill erection Emergency inerting systems for coalgrinding applicationsTitle image Emergency inerting systems for coalgrinding applications When coal is ground in a mill explosions are a significant risk Inerting systems are an effective way to remove oxygen from the system thus preventing explosions coal grinding mill erection,vertical coal grinding mill vibrating sieve ...

Dynamic steam inerting system for a ball tube mill ...

Coal pulverizing system explosions during the last few years have pointed to the need of developing inerting systems for preventing such incidents. The greater use of western subbituminous coals (with their higher tendency for spontaneous ignition) is a contributing factor to the increased frequency of coal pulverizer explosions.

Safety, Fire, Environment | Mill (Grinding) | Industrial ...

WELCOME. TO SAFETY PROCEDURE. BOWL MILLS ARE DESIGNED FOR 50 PSI () EXPLOSIO N PRESSURE. AS PER NFPA 85 E. MOST OF THE COMPONENTS ARE DESIGNED FOR LONG WEAR LIFE AND CONTINOUS OPERATION. MILL FIRE Reasons for mill fire in vertical mills:High. volatile matter in coal with high PA Temp.high inlet and outlet temp.(it should be < 85 c) .

aHak: Foam inerting

Prior to a foam inerting procedure, one of our specialists will visit your site to prepare a detailed operating procedure. They will assess the lay down areas, injection points etcetera to ensure smooth and safe operations in minimal time. FOAM INERTING ONLINE Modifications involving hot works were required on a large crude oil tank in Italy.

Latest Posts

- كسارات حجر الفك الهيدروليكي المصنعين في chna

- مصانع مطاحن الكرة للبيع في مصر

- ملموسة سحق آلة المملكة المتحدة

- المزاد من كسارة حجر

- سلامة قائمة تشغيل محطة التكسير

- العمل لكسارة الحجر تأثير

- إمدادات تعدين الحجر الجيري

- عيوب التعدين حفرة مفتوحة

- الانتهاء من كسارة الفك

- تأجير وبيع كسارة الفك كاليفورنيا

- محطة الفرز المتنقلة لتعدين الفحم

- معالجة الذهب بالساعة

- آلة محطم الخرسانة تورونتو

- محطم الخرسانة المتنقلة أوكلاند

- معدات تكسير الصخور الألمانية

- homemade sluice box plans

- beach sand cleaning systems html

- 1m3 rcc conrete weight standard

- cost of quarry stone crusher in uae

- marble mining machines

- rail car pusher for sale

- line sand making crusher equipment

- new portable heavy rock crusher for sell

- emalahleni coal mines

- supply of stone crushed sand

- high chrome liner for coal mill model bbd

- rahang crusher mobile untuk pengolahan marmer

- crusher batu untuk dijual digunakan pabrik penggilingan batu filipina

- industrial grinding machine upto 6 microns in india

- hammer crusher jacobsen