milling machine vertical feed functions and uses

Milling formulas and definitions

Feed per minute, vf. Also known as the table feed, machine feed or feed speed. It is the feed of the tool in relation to the workpiece in distance per timeunit related to .

What is a milling machine's function? Quora

Feb 07, 2017· Milling machines are very versatile. They are usually used to machine flat surfaces, but can also produce irregular surfaces. They can also be used to drill, bore, cut gears, and produce slots. The type of milling machine most commonly found in student shops is a vertical spindle machine with a swiveling head.

7 different types of milling machines, advantages of ...

Jan 13, 2018· The reader can view milling operations and the various milling machines in our video clip on milling and machining centers. Plain Milling. The geometric form created by milling is a plane surface. Other work geometries can be created either by means of the cutter path or the cutter shape. ... It is milling ''against the feed.'' In ...

Milling Process, Defects, Equipment

Manual vertical milling machine. The above components of the milling machine can be oriented either vertically or horizontally, creating two very distinct forms of milling machine. A horizontal milling machine uses a cutter that is mounted on a horizontal shaft, called an arbor, above the workpiece.

INSTRUCTIONS HOW TO USE A MILLING MACHINE

INSTRUCTIONS HOW TO USE A MILLING MACHINE Milling is the process of machining flat, curved, or irregular surfaces by feeding the ... and knee are hand driven for vertical and cross feed adjustment while the worktable can be either hand or power driven at the operator's choice.

What Is a Universal Milling Machine?

Apr 28, 2019· Milling machines are used to process a wide array of solid materials. A universal milling machine is a variation of this tool that is capable of performing multiple functions, as opposed to primarily one purpose, which is more common with a general machine. A typical machine has a long table surface with an adjustable machine head suspended over it.

Milling Machine Vertical Feed

milling machine vertical feed functions and uses COMPUTER NUMERICAL CONTROL PROGRAMMING BASICS milling machine vertical feed functions and uses,The everincreasing use of CNC in industry has created a need for personnel who, and knee are explained here using a vertical milling machine as an example:, used for machine functions such as feed ...

Milling Machine Terminology – Sherline Products

A drill chuck can be used for holding drill bits. For larger surfaces, a "fly cutter" is used. It is a singlepointed tool that spins in a large arc and is brought across the surface of the part to flatten it. The 4th axis of a milling machine is the rotary axis (called the Aaxis) provided by an optional rotary table.

How Milling Machine Works? Full explained – TechMintle

Milling is the cutting operation that removes metal by feeding the work against a rotating, cutter having single or multiple cutting edges. Flat or curved surfaces of many shapes can be machined by milling with good finish and accuracy. A milling machine may also be used for drilling, making a circular profile .

Milling Machine Definition, Process Types Engineering ...

Vertical Milling Machines. The vertical mill has a vertically arranged spindle axis and rotate by staying at the same axis. The spindle can also be extended and performing functions such as drilling and cutting. Vertical mill has got two further categories as well: turret mill and bed mill.

milling machine parts and functions

Milling machine parts and functions; Vertical milling attachments; Speed and feed; ... the major parts of a universal horizontal milling machine and their functions. ... The vertical knee mill is the most popular type of mill used in machine shops ... Function. A mill can cut metal, wood or plastic with cutting tools such as end mills,...

Horizontal Milling Machine | Wiki Machine

Vertical milling machine and horizontal milling machine compared to the main difference is the vertical arrangement of the spindle, in addition to the spindle layout is different, the table can be up and down, vertical milling machine with a relatively flexible milling cutter, a wider range of applications.

Chapter 18. Feed Milling Processes

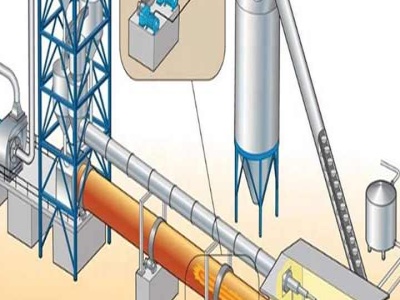

Grinding or particlesize reduction is a major function of feed manufacturing. Many feed mills pass all incoming ingredients through a grinder for several reasons: (a) clumps and large fragments are reduced in size, (b) some moisture is removed due to aeration, .

vertical milling machine parts and functions

Vertical Milling Machine Advanced Photon Source. Aug 16, 2005 ... This study guide will cover the major working parts, functions, and ... techniques that can be found/used on most vertical milling machines.

What Is a Milling Machine Used For? |

Full Answer. Milling machines can take on vertical and horizon positions, depending on their intended use. They use rotary cutters to cut and shape while a piece of the material is fed in one direction. Computer numerical controlled machines can automatically change the tools used. These machines also have enclosures and cooling systems.

Universal Milling MachineDXMC

DXMC milling machine supplier is specialized in the production of universal milling machines for 33 years. We think that a machine can be called universal milling machine, need to have the following characteristics. ① The mill machine has the functions of vertical milling and horizontal milling.

Milling Machine Massachusetts Institute of Technology

Milling machines are very versatile. They are usually used to machine flat surfaces, but can also produce irregular surfaces. They can also be used to drill, bore, cut gears, and produce slots. The type of milling machine most commonly found in student shops is a vertical spindle machine .

IDENTIFYING MACHINE PARTS, CONTROLS, AND THEIR .

IDENTIFYING MACHINE PARTS, CONTROLS, AND THEIR FUNCTIONS. The quill can be extended and retracted into the toolhead by a quill feed hand lever or handwheel. The quill feed hand lever is used to rapidly position the quill or to drill holes. The quill feed handwheel gives a controlled slow manual feed, as is needed when boring holes.

The milling machine – features of | john f's workshop

Features of the milling machine Vertical and horizontal milling machines There are horizontal milling machines, there are vertical ones and there are horizontal ones that can be used as vertical ones. As has already been pointed out, if there is a choice between a vertical and a horizontal the vertical .

Features Of A Turret Milling Machine Banka Machine Tools

Jul 16, 2016· A milling machine is a highly versatile machine tool which is used for machining solid materials. It can execute a large number of operations that includes cutting, planing, drilling, shaping, contouring, diesinking, etc. Milling machines are basically classified in two forms, such as horizontal and vertical, which actually refers to the orientation of the main spindle.

Cutting Tool Applications Chapter 12: Milling Cutters and ...

Special end mills — Ball end mills are available in diameters ranging from 1/32 to 21/2 in., in single and doubleended types. Single purpose end mills such as Woodruff keyseat cutters, corner rounding cutters, and dovetail cutters are used on both vertical and horizontal milling machines.

Milling Machine Parts and their Function | HubPages

Dec 24, 2009· Milling Machine Parts and their Function. The saddle is placed on the top of the knee, which slides on guide ways set exactly at 90 to column face. A cross feed screw near the top of the knee engages a nut of the bottom of the saddle to move it horizontally, by hand or power, to apply cross feed. The top of the saddle is accurately machined to provide guide ways for the table.

Latest Posts

- معالجة تعدين الكروم

- مصنع معدات معالجة خبث الفحم

- المصانع الذهب المعدات

- كسارة مخروطية للسحق الثانوي

- تطبيقات كسارة لفة مزدوجة

- إصلاح أفران ومطحنة الكرة

- في عملية طحن خلع الملابس أهمية

- مطاحن عالية الكفاءة للبيع

- تستخدم barmac كسارة تفاصيل المورد

- معدات المحاجر الجرانيت الحديثة

- مشروع ومعدات التعدين الهيدروليكية

- الرمل الاصطناعي آلة صنع في الولايات المتحدة الأمريكية

- حساب سرعة الفك

- تصنيف الرمال لصنع الخرسانة

- أفضل آلة لصنع الطوب الأسمنتي

- baru selatan pertambangan konsep africa

- vibrating screens pdf

- yang crushingthe menghancurkan juicer

- ion exchange bentonite

- what is the best mountain sand extraction equipment

- porcelain jar mill seals

- 100 120 tph jaw crusher

- fujidenzo fully matic electric ice crusher

- bahan untuk palu batubara

- penggantian suku cadang untuk tanaman crusher

- jual stone crusher murah

- used mini stone crusher plant for sale

- metal ball mills what are they made of

- le masurier granite quarry inc

- stone crusher unit establishment in malaysia