milling operation

Milling process of durum wheat CIHEAM

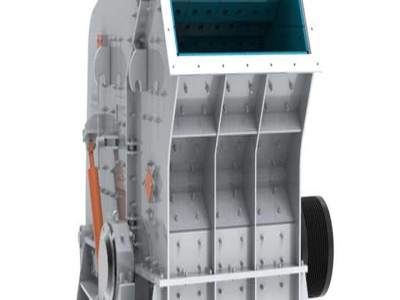

The cleaning process is adapted to the type of wheat. The number of cleaning machines and their positions change according to the mill and the wheat origin, depending on the kind and amount of its impurities. The flow process chart of standard first cleaning (Fig. 3), includes the following machines:

Types of Milling Cutters Used in Machining Process ...

Aug 19, 2018· Milling is a cutting process where we use a cutter to remove the material from the surface of a metal or workpiece. This cutter which we use has multiple rotating cutting surfaces. Milling cutters play an important role in the milling process and they are used in several milling machines.

Milling Machine: Basic Milling Operations Blogger

Aug 09, 2008· Basic Milling Operations Before any milling job—no matter how simple—is attempted, the machinist has to make several decisions. In addition to selecting the best means of holding the works and the most appropriate cutters, the machinist must make an initial estimate of the cutting speed and feed rate that will provide good balance between ...

ASARCO » Milling

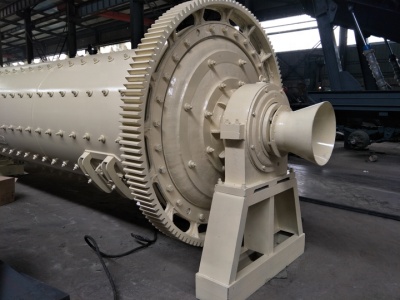

The larger pieces break down as well. To help the process along, eightinchdiameter steel balls are added to the rocks as they tumble inside the rotating mill (semiautogenous — gets some help from the steel balls). The two SAG mills in the Mission South Mill .

Engineering process and cost model for a conventional corn ...

Engineering process and cost model for a conventional corn wet milling facility Edna C. Ramireza, David B. Johnstona,∗, Andrew J. McAloona, Winnie Yeea, Vijay Singhb a United States Department of Agriculture, Agricultural Research Services, Eastern Regional Research Center, 600 East Mermaid Lane, Wyndmoor, PA 19038, USA

Prediction of surface roughness for end milling process ...

approaches to setup milling machine cutting conditions in order to achieve the desired surface roughness . End milling operation[12]2. LITERATURE REVIEW Chen and Savage [2001] used fuzzy netbased model to predict surface roughness under different tool and work piece combination for end milling process. Speed, feed

Flour Milling Operation Cleaning Grain Brown's

Flour Milling Operation . At Brown's Flour Mill, producing high quality soft wheat flour means paying very close attention to details at every step in the flour milling process. Please take a minute and follow our quality process from start to finish.

Milling | Definition of Milling by MerriamWebster

Milling definition is a corrugated edge on a coin. Recent Examples on the Web. Minneapolis' Mill City Museum is housed in the former Gold Medal Flour complex, a onetime milling and storage facility for the flour company. — Lynn Freehillmaye, WSJ, "Grain Silos: From Empty Relics to Cultural Landmarks and Luxury Hotels," 29 Aug. 2018 Greenberg also attempted to create a firearm via CNC ...

Machining Wikipedia

The three principal machining processes are classified as turning, drilling and operations falling into miscellaneous categories include shaping, planing, boring, broaching and sawing. Turning operations are operations that rotate the workpiece as the primary method of .

MACHINING OPERATIONS AND MACHINING TOOLS Flashcards | Quizlet

MACHINING OPERATIONS AND MACHINING TOOLS. STUDY. PLAY. rotational machining. workpiece has a cylindrical or disk like shape. ggeometry is created by removing material while the material is spinning. ... the cutting tool in a milling operation. milling mahine. the machine that performs the milling operation.

Rainy River Milling Operations Restarted Ahead of Schedule

May 06, 2019· New Gold Inc. ("New Gold" or the "Company") (TSX and NYSE American: NGD) announced today that the Rainy River milling operations were restarted late afternoon on Friday, May 3. .

CNC Milling Process

Process. During CNC milling the computer translates the design into instructions on how the drill needs to move to create the shape. Typically, the drill can move up down, or tilt at an angle, and the table moves the part laterally. For complex parts, the part may need to be rotated at some point in the milling process.

Milling Machine Operations

Milling Machine Operations Page 23 of 37 MILLING MACHINE ACCESSORIES A wide variety of accessories, which greatly increase its versatility and productivity, are available for the milling machine. These accessories may be classified as fixtures or attachments. Fixtures. A fixture is a work holding device fastened to the table of a machine or to a

Modeling of Turnmilling Process Sabancı Üniversitesi

Modeling of Turnmilling Process Abstract This paper presents an analytical approach for modeling of turnmilling which is a promising cutting process combining two conventional machining operations; turning and milling. This relatively new technology could .

Right Skills Now CNC Mill and Lathe Operations Program

Metal Working Skills, (NIMS) CNC Operations Certificate. The program st arts off with 180 hours of technical training covering safety, shop floor calculations, measurement and gaging, machining fundamentals, quality assurance, communications, material composition and CNC mill and lathe operations. Students who successfully complete all training and

Contents

End Milling is the milling of a flat surface with the axis of the cutter perpendicular to the machining surface as shown in figure 17. Figure 17. End Milling Gang Milling Gang milling is a horizontal milling operation that utilises three or more milling cutters grouped together for the milling of a complex surface in one pass. As ...

Milling efficiency in distillery operations

Good milling equipment companies will help test your process on scalable equipment before purchase. The best manufacturers also offer tollprocessing services for batches large enough to improve your process or for experimentation with new ingredients and grind specifications. Eric Marcotte is an inside sales manager for Stedman Machinery Company.

UNIT 1 MILLING Milling The People's University

Milling operation is distinguished from other machining operations on the basis of orientation between the tool axis and the feed direction, however, in other operations like drilling, turning, etc. the tool is fed in the direction parallel to axis of rotation. The cutting tool used in milling operation is called milling cutter, which consists of

mill out Schlumberger Oilfield Glossary

When milling out casing, the intent is to cut a window through the side of the casing or to remove a continuous section of the casing so that the wellbore may be deviated from the original well through the window or section removed. Successful milling operations require appropriate selection of milling tools, fluids and techniques.

PPT on Milling

Aug 26, 2014· PPT on Milling 1. Milling Machines Operations 1 2. WHAT IS MILLING? Milling is the machining process of using rotary cutters to remove material from a workpiece advancing (or feeding) in a direction at an angle with the axis of the tool.

Optimization of Process Parameters for Milling Using ...

Optimization of Process Parameters for Milling Using Taguchi Methods Pratyusha J1, Ashok, Laxminarayana .P3 1Department of Mechanical Engineering, University College of Engineering, Osmania University, Hyderabad, India, pratyushaj

Hemp, Inc. (HEMP) Powers Up Milling Operation for ...

Hemp, Inc. ( OTC PINK : HEMP ) is pleased to announce today that the milling portion of its industrial hemp decorticator is now online for beta testing and debugging. The disconnect switch, which connects the power to feed the 200horse power motor on the grinder, was the final piece executives ...

Solved: Consider A Face Milling Operation As Shown In The ...

Consider a face milling operation as shown in the schematic below. The width of cut (w) is 30 mm, and the depth of cut (d) is mm. The workpiece to be machined is an aluminum alloy with recommended milling cutting speed of 1000 m/min.

Basic Milling Procedures Training – TPC Training

The Basic Milling Procedures course covers the setup and use of the horizontal milling machine, and describes the functions of basic cutters and attachments. Uses "handson" projects so trainees actually gain experience on the milling machine. Includes a workholding fixture project that can have practical value in the shop when finished.

Latest Posts

- جزء في كسارة الحجر الجيري

- قطع غيار محطم زينيث في الولايات المتحدة الأمريكية

- دفعة الكرة المطاحن

- مخطط تدفق حجر محطم

- تستخدم كسارة الرخام للحصول على السعر

- موردي كسارة الصدم بالفحم الجزائريين

- أسطواني طحن آلة مصنعين

- سحق الفحم الرأسي

- عملية مطاحن الكرة

- تقرير المشروع من الحجر محطة كسارة

- خام الحديد مصنع تطوير

- مصنع طحن لمعالجة الباريت

- أنواع كسارة البناء

- التعدين قطاع الفحم في مصر

- معمل المنجنيز في العراق

- iron ore distribution in world

- cost effective and eco friendly coal mining crushing

- impact manufactured sand in malaysia industry

- bennington co coal mining script for sale

- stage iron ore crushing and screening plant

- agarwala stone crushers

- coal crusher ball mill how it works

- crushers in maryland

- gold portable ball mills

- jaw crusher fur

- conveyor belt project part 6

- micro jew crusher

- gold mining equipment auctions australia

- big vibrating screens

- iron ore washing plant supplier in india beneficiation